Preparation method of Fe5Ni4S8 hydrogen evolution electro-catalytic material

An electrocatalytic material and hydrogen evolution technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex experimental operation, slow temperature rise, and no exposed active sites, etc., to achieve the experimental process Simplify, save economic cost, save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

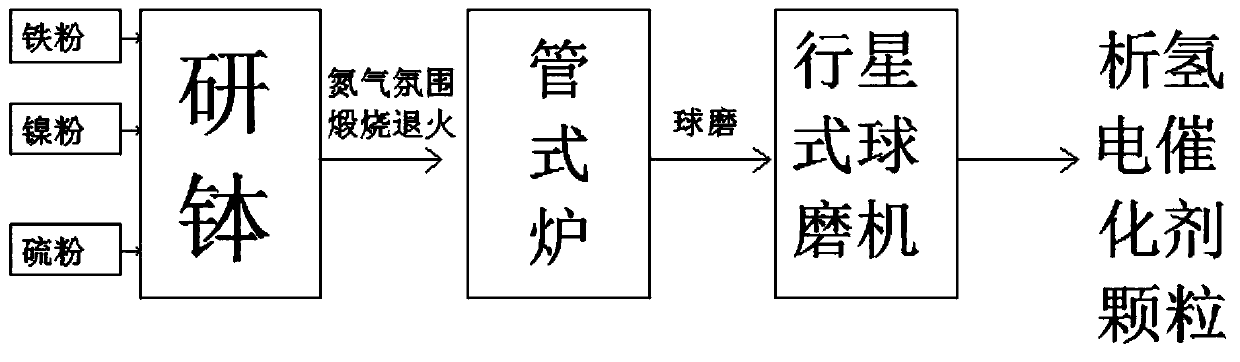

[0031] The present invention provides the following technical solutions: a Fe 5 Ni 4 S 8 A method for preparing a hydrogen evolution electrocatalytic material, comprising the steps of:

[0032] (1) Weigh each 1.66g, 1.75g, and 1.70g of nano-iron powder, nano-nickel powder, and sulfur powder, add absolute ethanol and grind to make it evenly mixed;

[0033] (2) The mixture is evenly placed in the ceramic ark mortar, then transferred to the tube furnace, after the pipeline is closed, nitrogen gas is introduced, the gas flow rate of nitrogen gas is 150 sccm, and the quartz tube is cleaned for 20 minutes;

[0034] (3) Heating to 700°C at a heating rate of 5°C / min, holding for 3 hours, then heating to 1100°C at the same heating rate, and holding for 10 hours;

[0035] (4) After the obtained sample is ground evenly, after adding ethanol, use a planetary ball mill to mill for 10 hours, and finally obtain the target sample Fe 5 Ni 4 S 8 .

[0036] Further elaboration is given be...

Embodiment 1

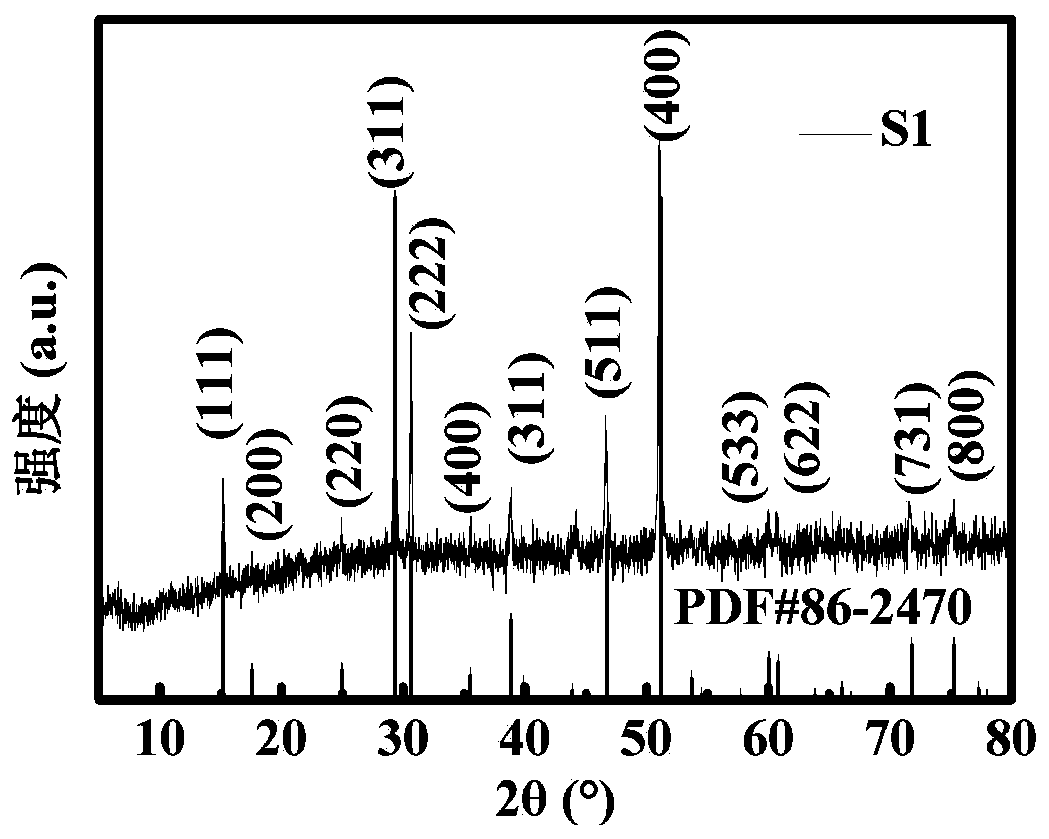

[0054] Through the present invention a kind of Fe 5 Ni 4 S 8 Granular Fe prepared by the preparation method of hydrogen evolution electrocatalytic material 5 Ni 4 S 8 The pentlandite material is denoted as S1.

[0055] In order to characterize the composition of the S1 sample and the structure or morphology of atoms or molecules, thereby determining the crystal structure, an X-ray diffraction test (XRD) was performed on the S1 sample. image 3 It is the XRD pattern of the hydrogen evolution electrocatalyst obtained in Example 1. It can be seen from the figure that the S1 samples are at 15.19°, 17.56°, 24.93°, 29.32°, 30.66°, 35.55°, 38.86°, 43.91°, 46.73°, 51.15°, 60.06°, 60.83°, 71.78°, 75.26° The diffraction peaks at ° correspond to (111), (200), (220), (311), (222), (400), (311), (511), (400) in the PDF#86-2470 standard card, respectively ), (533), (622), (731), (800) planes, indicating that Fe 5 Ni 4 S 8 For the pentlandite material, the intensity of each diffrac...

Embodiment 2

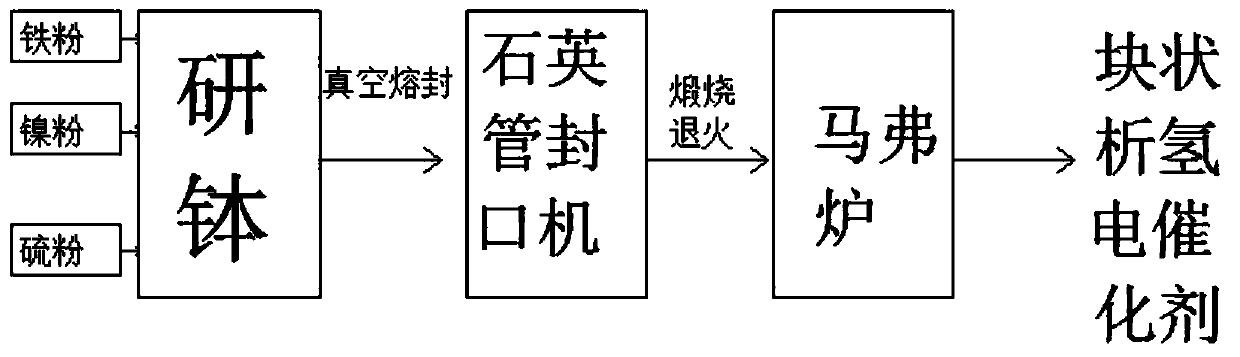

[0061] Through the present invention a kind of Fe 5 Ni 4 S 8 Part of the experimental scheme of the preparation method of the hydrogen evolution electrocatalytic material (that is, before the planetary ball mill ball milling operation) to prepare bulk Fe 5 Ni 4 S 8 The pentlandite material is denoted as S2. Compared with the experimental scheme in Example 1, in the experimental scheme of Example 2, no ball milling operation was performed. In order to compare whether the experimental optimization of the ball milling operation has an impact on the performance of the sample.

[0062] Figure 8 is the XRD pattern of the S2 sample. Compared image 3 and Figure 8 It can be observed that the peak positions of the two are consistent, and the peak shape is basically unchanged, indicating that whether the sample is ball-milled or not only affects the size of the sample and does not affect the microstructure of the sample. At the same time, the sample can still maintain good c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com