Drift-pillar-free sublevel barnyard caving mining method of open pit transferred underground transitional period

A technology of open-pit to underground and segmental caving method, which is applied in the field of underground mining to achieve the effect of reducing loss and dilution rate, reducing ore residue, and reducing the amount of mining engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

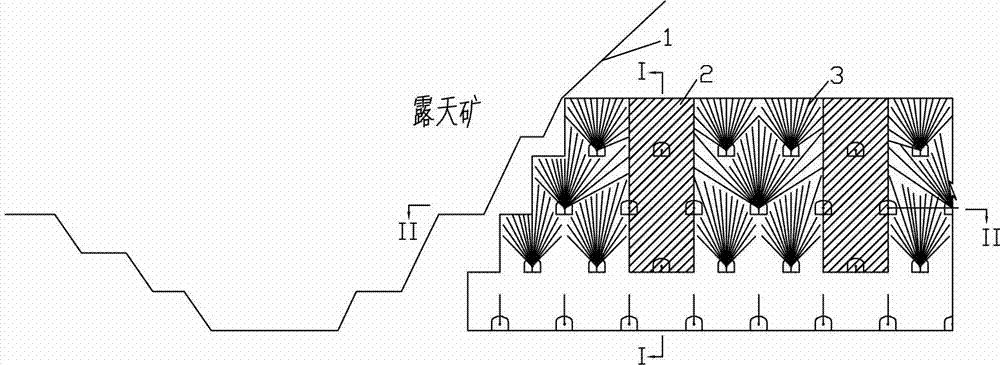

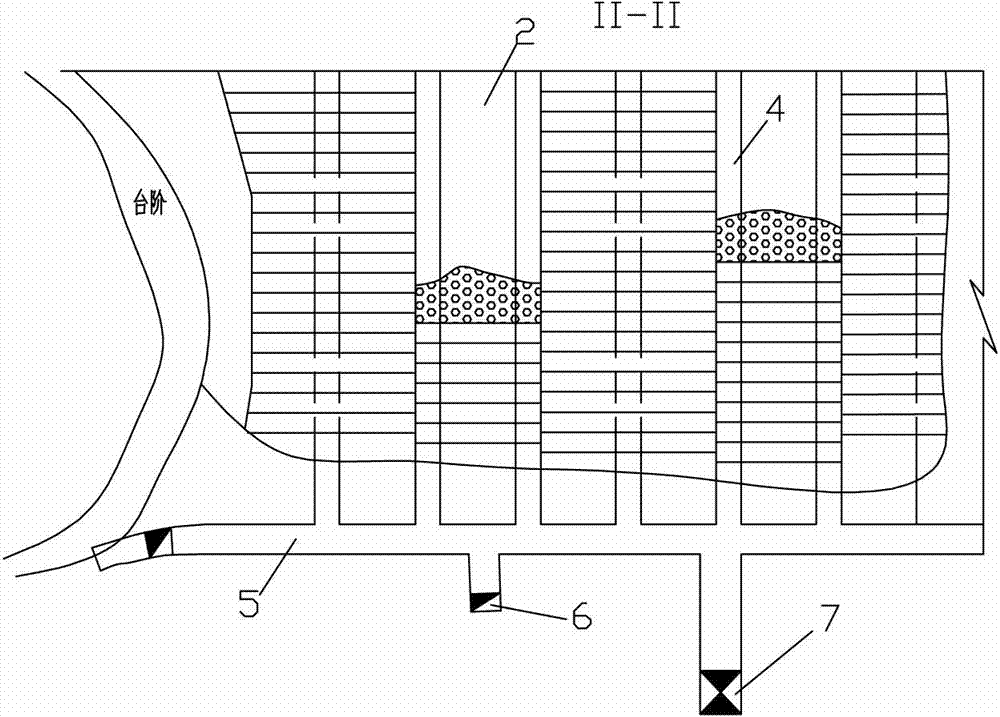

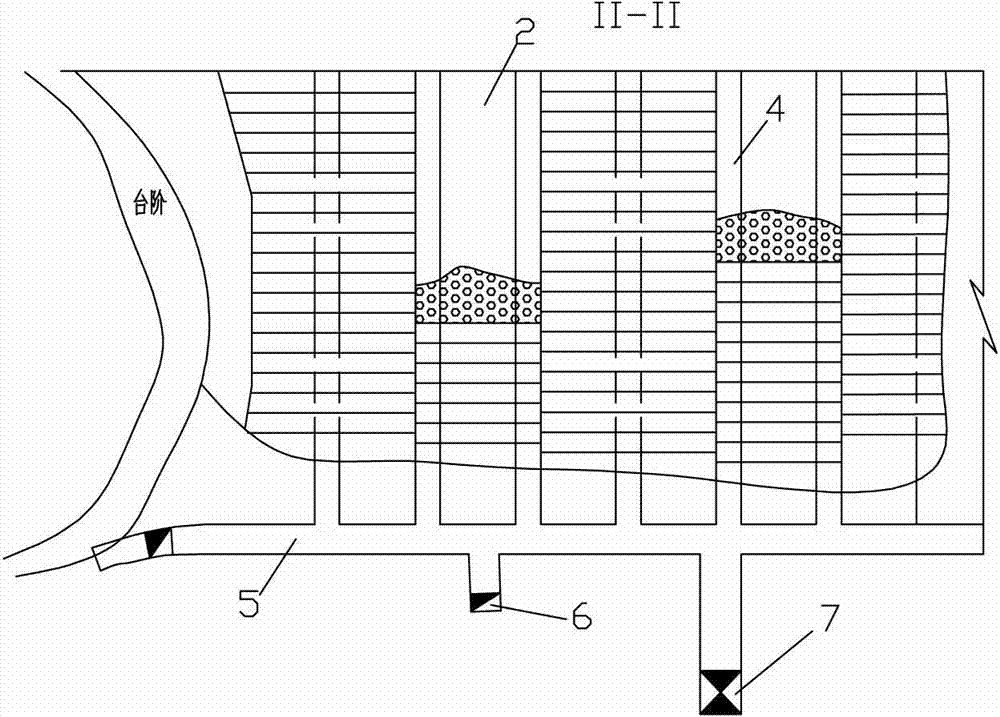

[0045] A certain mine plans to complete the transformation from open-pit mining to underground mining from June 2012, and has completed the layout of diamond-shaped access roads and the layout of upward fan-shaped middle and deep holes. The underground engineering design of the mine is roughly as follows: the stage height is 72m, and the section height is 18m. The mined ore is discharged to the -141m main transport flat tunnel through the chute 6, and loaded into the equipment shaft 7 via vibration. It is transported to the surface, and then transported to the ore dumping site through the open-pit transportation system. Each layer is connected by the slope in the mining area, and the entrance of the slope is located near the open-pit -70m transportation line. The slope of the ramp is 15%.

[0046] The mining plan of the -69m section of the mine is shown in the figure Figure 9 As shown, for the safety of the open-pit slope, a 20m security pillar is reserved (such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com