A casting method of large-size lead-free free-cutting aluminum alloy cast rod

An aluminum alloy, large-scale technology, applied in the field of aluminum alloy casting, can solve the problems of poor extrusion processing performance of free-cutting aluminum alloy cast rods, deterioration of mechanical properties of free-cutting aluminum alloys, and coarse second-phase compounds of composition segregation. Improve the uniformity of structure and composition and extrusion processing performance, eliminate hot cracks, and facilitate the effect of composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

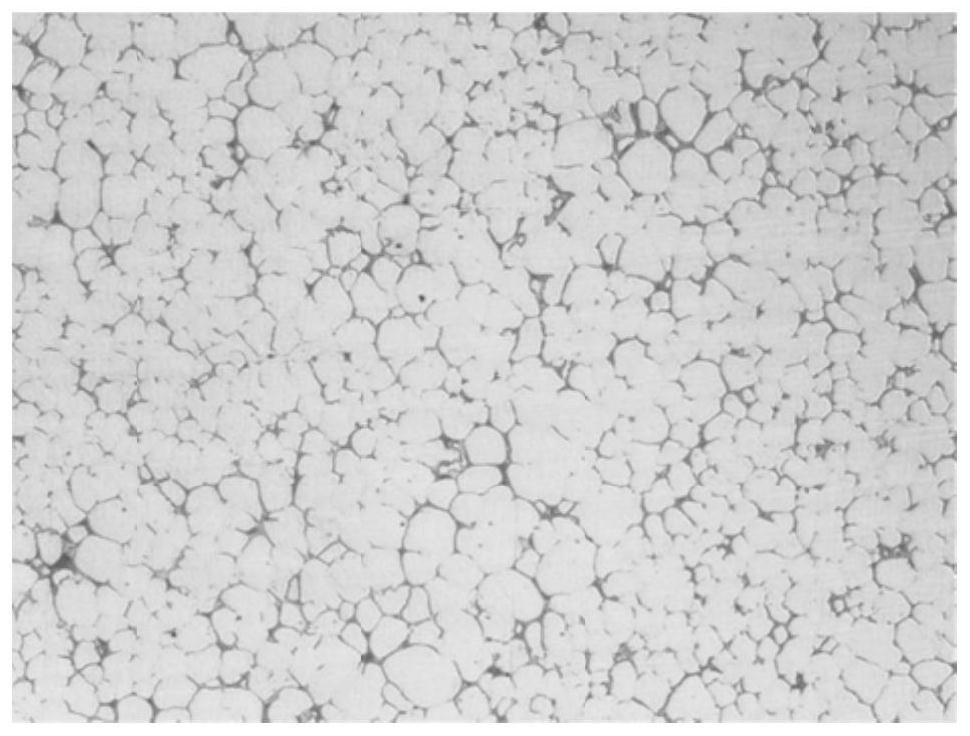

Embodiment 1

[0060]A lead-free-cut aluminum alloy cast rod consisting of a percentage of mass: Cu 4.82%, Mg1.43%, Si 1.18%, Sn 0.71%, BI 0.19%, Mn 0.17%, Zr 0.015%, C 0.003 %, BA 0.1%, Fe0.13%, margins are Al and inevitable impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount of impurity element is ≤0.15%.

[0061]The lead-free-cutting aluminum alloy cast rod casting method includes the steps of:

[0062](1) According to the composition and mass percentage of the aluminum alloy cast rod, the aluminum content of 99.85% is selected from 99.9%, the magnesium content is 99.9%, the tin ingot, the ingam content of 99.9%. Ingots, Al-50Cu alloys, Al-20Si alloy, Al-10MN alloy, Al-10ba alloy and Al-5ZR-1C alloy are ingredients for raw materials;

[0063](2) The melting aluminum furnace is heated by the furnace bottom electromagnetic stirring function to heat the aluminum ingot at 785 ° C, then add magnesium ingot, tin ingot, bismuth ingot, Al-50Cu alloy, Al-20Si alloy, Al-10MN a...

Embodiment 2

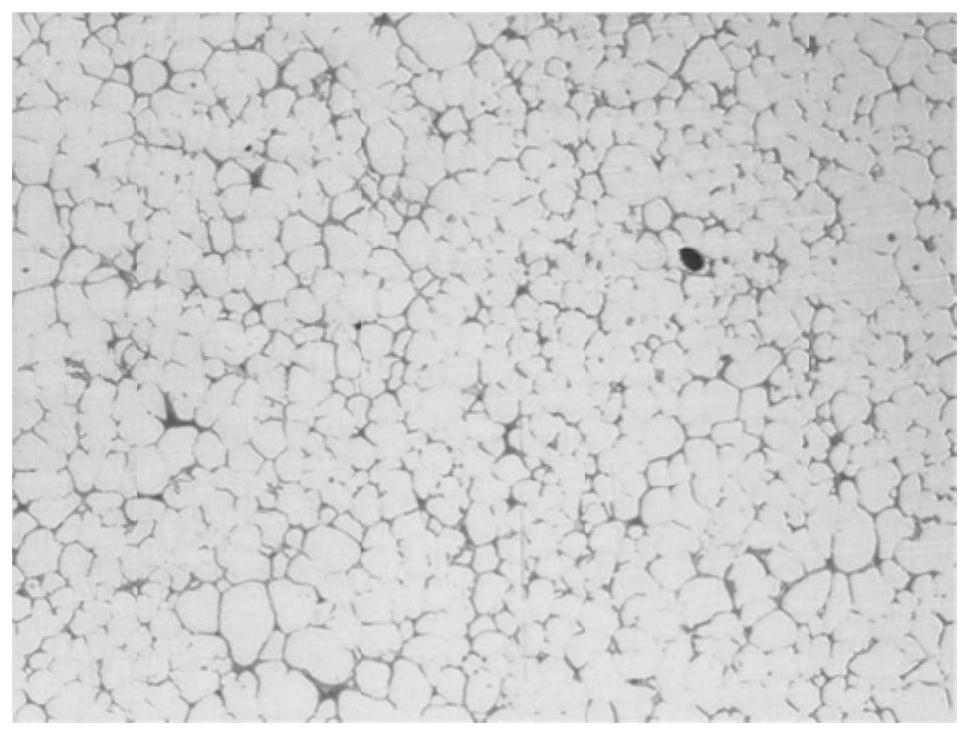

[0069]A lead-free-cut aluminum alloy cast rod consisting of a percentage of mass: Cu 4.78%, Mg1.47%, Si 1.14%, Sn 0.75%, Bi 0.15%, Mn 0.15%, Zr 0.01%, C 0.002 %, BA 0.12%, Fe0.14%, margin is Al and inevitable impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount of impurity element is ≤0.15%.

[0070]The lead-free-cutting aluminum alloy cast rod casting method includes the steps of:

[0071](1) According to the composition and mass percentage of the aluminum alloy cast rod, the aluminum content of 99.85% is selected from 99.9%, the magnesium content is 99.9%, the tin ingot, the ingam content of 99.9%. Ingots, Al-50Cu alloys, Al-20Si alloy, Al-10MN alloy, Al-10ba alloy and Al-5ZR-1C alloy are ingredients for raw materials;

[0072](2) The melted aluminum furnace is heated by the furnace bottom electromagnetic stirring function to heat the aluminum ingot at 780 ° C, then add magnesium ingot, tin ingot, bismuth ingot, Al-50Cu alloy, Al-20Si alloy, Al-10Mn allo...

Embodiment 3

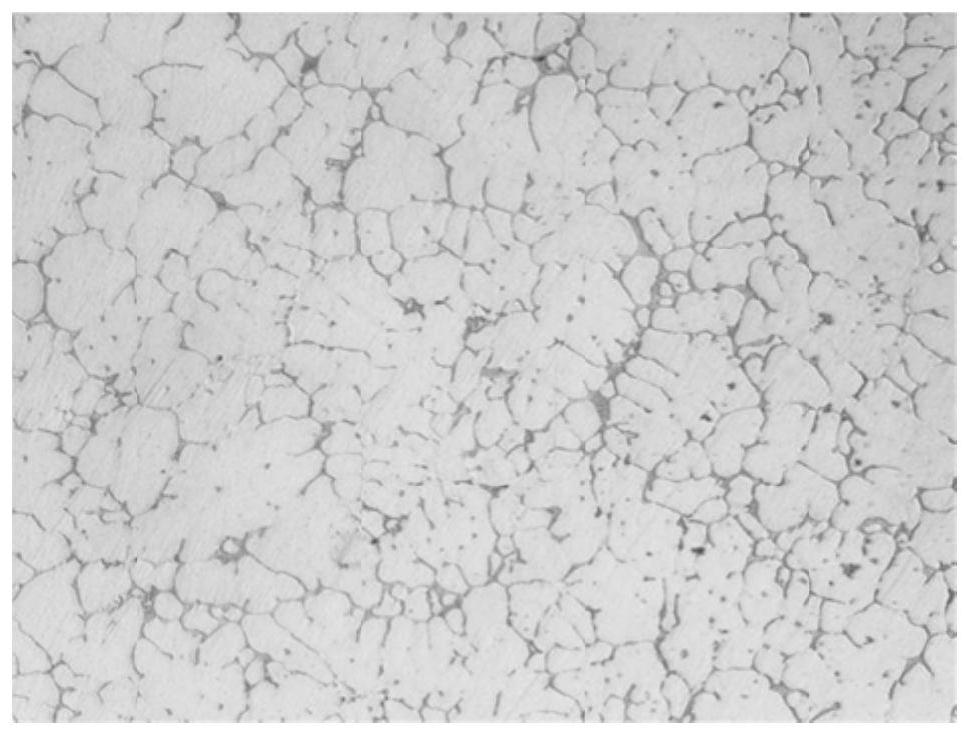

[0078]A lead-free-free-cut aluminum alloy cast rod consisting of 4.86%, Mg1.39%, Si 1.22%, Sn 0.65%, 0.25%, Mn 0.18%, Zr 0.02%, C 0.004. %, BA 0.08%, Fe0.11%, margin is Al and inevitable impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount of impurity element is ≤0.15%.

[0079]The lead-free-cutting aluminum alloy cast rod casting method includes the steps of:

[0080](1) According to the composition and mass percentage of the aluminum alloy cast rod, the aluminum content of 99.85% is selected from 99.9%, the magnesium content is 99.9%, the tin ingot, the ingam content of 99.9%. Ingots, Al-50Cu alloys, Al-20Si alloy, Al-10MN alloy, Al-10ba alloy and Al-5ZR-1C alloy are ingredients for raw materials;

[0081](2) The melting aluminum furnace is heated with a furnace base with an electromagnetic stirring function to heat the aluminum ingot at 790 ° C, then add magnesium ingot, tin ingot, bismuth ingot, Al-50Cu alloy, Al-20Si alloy, Al-10Mn alloy and Al- The 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com