A kind of FRP pultruded radome for 5G base station and preparation method thereof

A fiberglass and radome technology, applied in the field of radome, can solve the problems of increasing the construction cost of 5G base stations, high manufacturing cost of plastic radome, and inability to meet the requirements of 5G base station construction, so as to optimize product appearance, improve anti-aging performance, and high The effect of excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

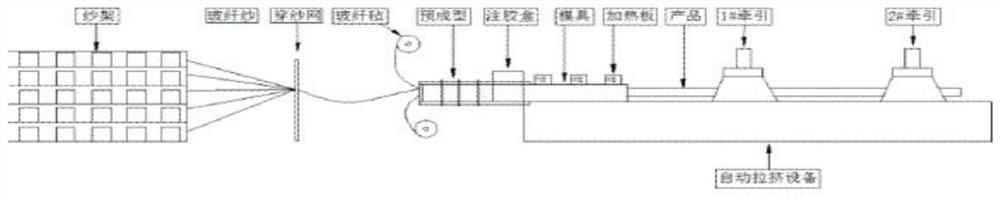

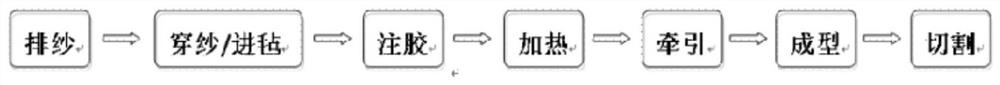

Method used

Image

Examples

Embodiment 5

[0030] Embodiment 5G base station uses fiberglass pultruded radome and preparation method thereof

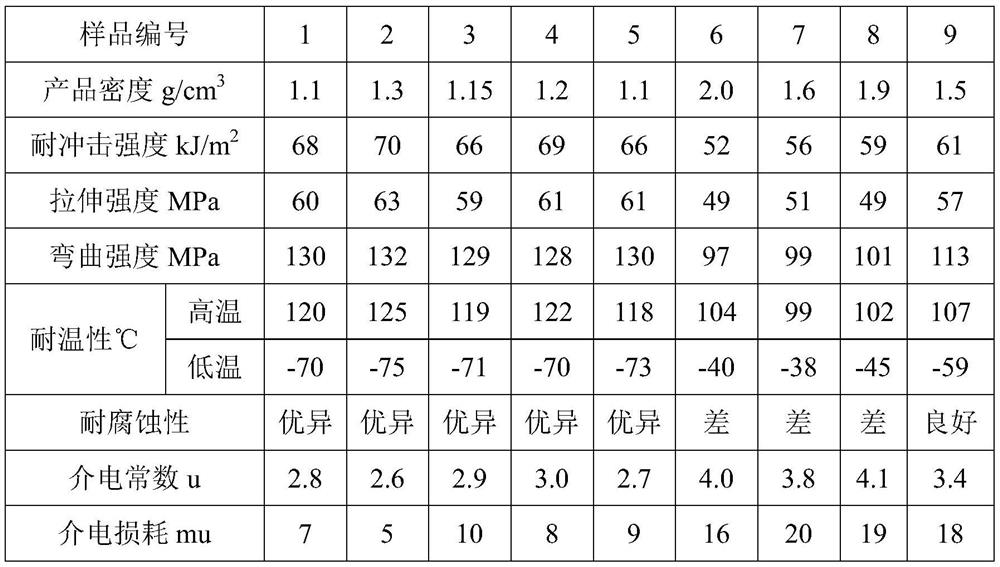

[0031] Table 1 lists the parts by weight of each component in the FRP pultruded radome for 5G base stations prepared in Examples 1-5 of the present invention.

[0032] Table 1 Formula of FRP pultruded radome for 5G base station

[0033] components Example 1 Example 2 Example 3 Example 4 Example 5 glass fiber 55 58.3 60 65 70 unsaturated polyester 40 5 45 55 60 flame retardant 0.25 0.4 0.3 0.35 0.5 Aluminum hydroxide 40 43 45 48 50 filler 3 3.6 3.2 3.8 4 PE powder 3 3.5 3.2 3.8 4 UV absorber UV-2 0.4 0.5 0.45 0.55 0.6 Antioxidants 0.4 0.5 0.45 0.55 0.6 Release agent 0.5 0.63 0.55 0.7 0.75 tert-butyl peroxybenzoate 0.5 0.65 0.55 0.7 0.75 Dibenzoyl peroxide 0.5 0.7 0.6 0.65 0.75 4-Cyclohexanediperoxydicarboxylate 0.12 0.15 0.14 0.16 0.18

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com