An improved super-long steel sheet pile foundation pit cofferdam

An improved technology for steel sheet piles, applied in infrastructure engineering, construction, etc., can solve the problems of difficult transportation of ultra-long steel sheet piles, sinking with piles, and high risk, so as to shorten the customization time, reduce the impact of water flow, and facilitate transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

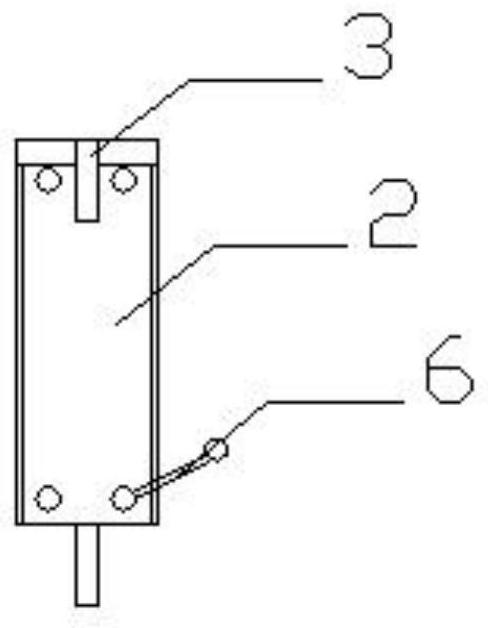

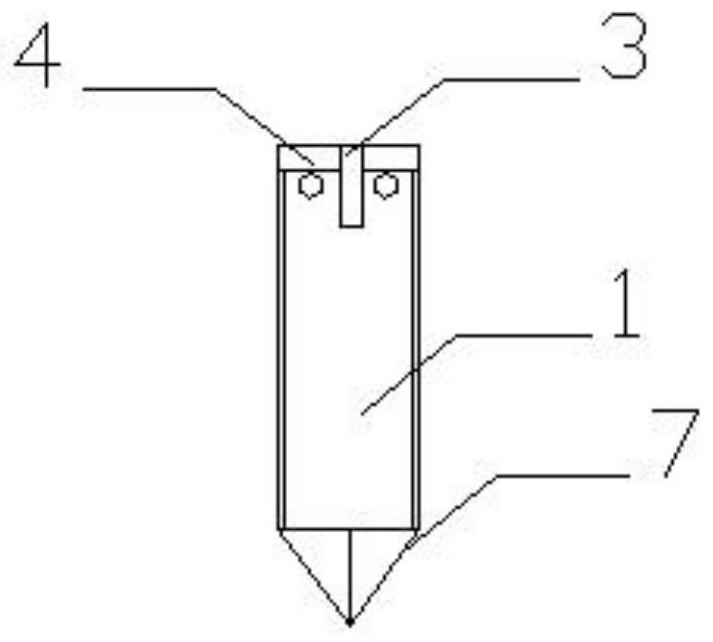

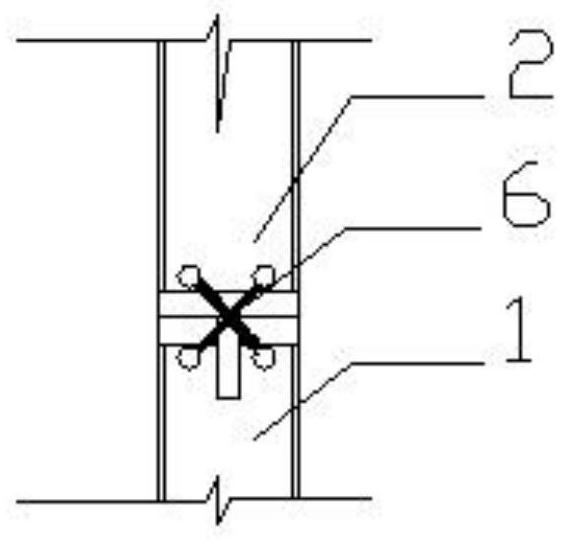

[0020] An improved ultra-long steel sheet pile, comprising a steel plate assembled at the pile head end and an assembled steel plate 2 at the pile body end, characterized in that: the bottom of the assembled steel plate at the pile head end is a reinforced pile head 7, and the assembled steel plate at the pile head end The upper part of 1 is provided with an assembled socket screw hole 3, and at least two locks are arranged on the upper part of the assembled steel plate at the pile head end, and a waterstop 4 is arranged on the top of the assembled steel plate at the pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com