Mobility-adjustable shielding putty and preparation method and application thereof

A fluidity and putty technology, applied in the field of nuclear radiation protection, can solve the problems of inability to fill the gap, the fluidity of the shielding putty cannot be adjusted, etc., and achieve the effect of short dry time, good shielding performance and bonding strength, and excellent shielding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

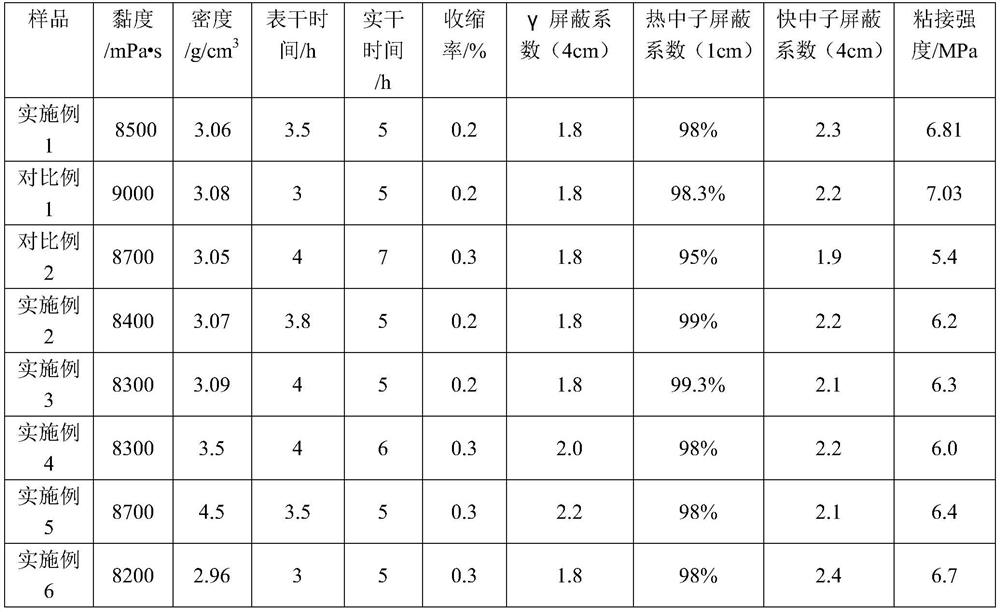

[0039] One kind of mobility adjustable shielding putty, in weight percent, consists of the following components:

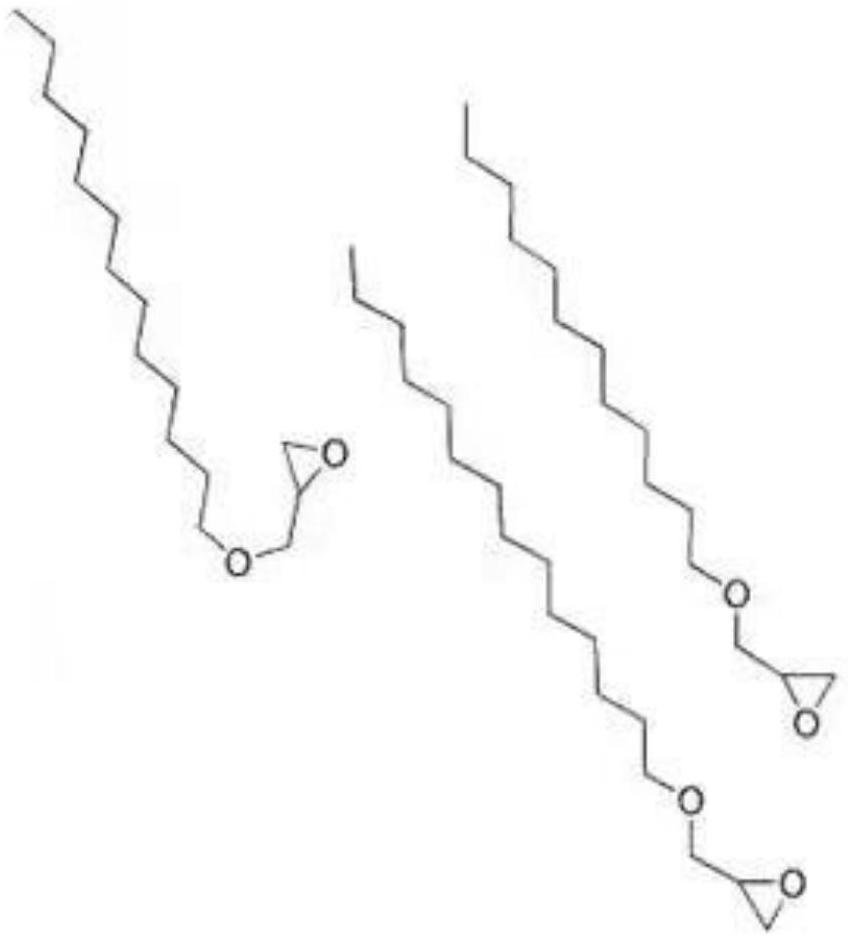

[0040] Epoxy 14.60wt%, aluminum hydroxide 14 wt% boron carbide 5.11wt%, lead powder 60 wt% reactive diluent having an epoxy group is 1.75%, cycloaliphatic amine curing agent 4.54wt%.

[0041] Preparation of the present embodiment is as follows:

[0042] A weight proportion of the epoxy resin and shown in the reactive diluent is added at the rate of the mixer 30r / min stirring 10min, A is the mixed component; will lead powder, aluminum hydroxide, boron carbide is added to the mixer 30r rate / min was stirred 15min B is the mixed components. The A, B two parts are mixed at a rate 30r / min of stirring 20min, component C was added (cycloaliphatic amine curing agent) uniformly mixed, and stirring was continued at a rate 70r / min to 60min.

Embodiment 2

[0050] One kind of mobility adjustable shielding putty, in weight percent, consists of the following components:

[0051] Epoxy resin 14.6 wt% of aluminum hydroxide 10 wt% boron carbide 9.11wt%, lead powder 60 wt% reactive diluent having an epoxy group is 1.75%, cycloaliphatic amine curing agent 4.54wt%.

Embodiment 3

[0053] One kind of mobility adjustable shielding putty, in weight percent, consists of the following components:

[0054] Epoxy resin 14.6 wt% boron carbide 19.11wt%, lead powder 60 wt% reactive diluent having an epoxy group is 1.75%, cycloaliphatic amine curing agent 4.54wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com