Ultra-fine grain hard alloy and preparing method thereof

A cemented carbide and ultra-fine grain technology, applied in the field of cemented carbide manufacturing, can solve the problems of reducing the strength and toughness of the alloy and weakening the performance of the alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

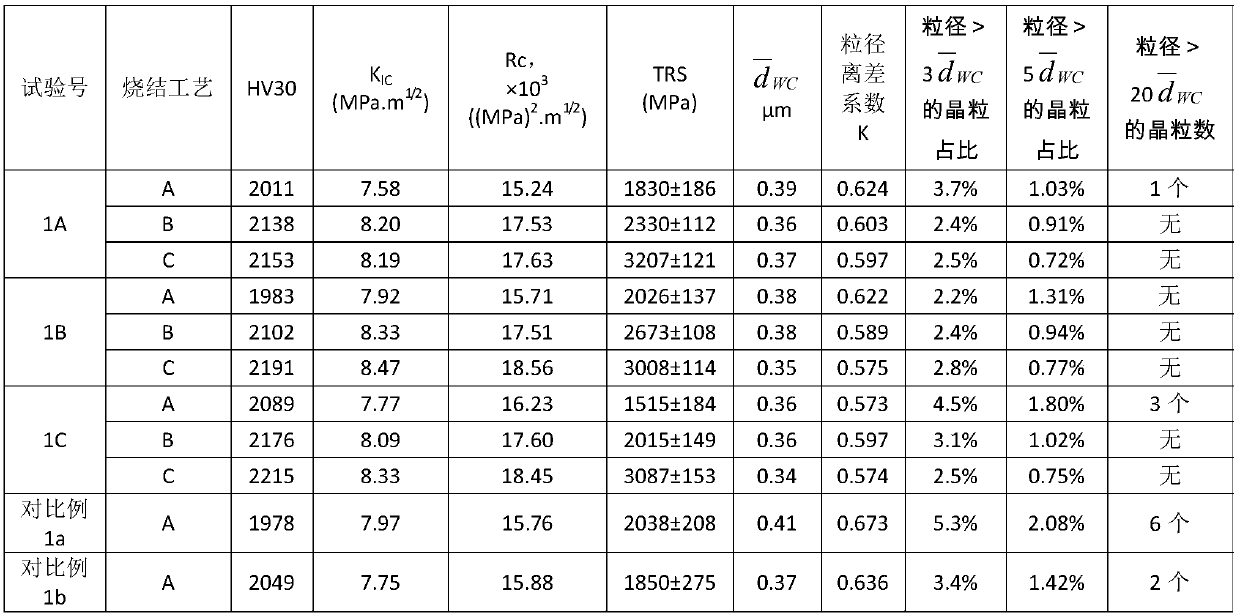

Embodiment 1

[0055] The weight percentage of prepared Co is 3.4%, and the average grain size The ultra-fine grain WC-Co cemented carbide is used in the manufacture of glass fiber, hardwood, CFRP, glass fiber and other cutting tools.

[0056] Step 1: Choose FSSS granularity 0.78μm (approximately the average grain size of the target alloy 2 times of ), WC powder with total carbon of 6.17%, fine-grained Co powder and fine-grained GGI powder (Cr 3 C 2 , VC, TiC) (the FSSS particle size is 1.76 μm, 1.85 μm, 1.33 μm, 1.42 μm) as raw materials;

[0057] Step 2: Put the WC and GGI powder raw materials into the ball mill according to the ratio in Table 1-1 for wet grinding and mixing, and at the same time add 5% paraffin wax according to the weight of the material, and use cemented carbide balls with a diameter of 10mm as the grinding body. The ball-to-material ratio is 10:1, the ball milling speed is about 75% of the critical speed, and after 70 hours of ball milling, it is unloaded and dried...

Embodiment 2

[0083] The weight percentage of prepared Co is 6.3%, and the average grain size The ultra-fine grained WC-Co cemented carbide is used to manufacture micro drills or micro milling cutters for PCB processing.

[0084] Step 1: Choose FSSS granularity About 0.56μm (about the average grain size of the target alloy 1.6 times of ), WC powder with total carbon of 6.14%, fine-grained nearly spherical Co powder and fine-grained GGI powder (Cr 3 C 2 , VC, TiC or Ti(C,N)) (the FSSS particle size is 1.76 μm, 1.77 μm, 1.53 μm, 1.18 μm, 0.86 μm) as raw materials;

[0085] Step 2: Put the WC and GGI powder raw materials into the ball mill according to the ratio in Table 2-1 for wet grinding and mixing. At the same time, add 4% paraffin wax according to the weight of the material, and use cemented carbide balls with a diameter of 6mm as the grinding body. The ball-to-material ratio is 8:1, the ball milling speed is 70% of the critical speed, after 64 hours of ball milling, it is unloade...

Embodiment 3

[0116] The prepared Co weight percentage is 14.6%, and the average grain size The ultra-fine grained WC-Co cemented carbide is used for end mills for efficient cutting of difficult-to-machine materials such as stainless steel and titanium alloys.

[0117] Step 1: Choose FSSS granularity About 0.58μm (about the average grain size of the target alloy 1.2 times of ), WC powder with total carbon of 6.11%, fine-grained nearly spherical Co powder and fine-grained GGI powder (Cr 3 C 2 , VC, TiC) (the FSSS particle size is 1.98 μm, 1.85 μm, 1.33 μm, 1.35 μm) as raw materials;

[0118] Step 2: Put the WC and GGI powder raw materials into the ball mill according to the ratio in Table 3-1 for wet grinding and mixing, and at the same time add 3% paraffin wax according to the weight of the material, and use cemented carbide balls with a diameter of 6mm as the grinding body. The ball-to-material ratio is 6:1, the speed of ball milling is 70% of the critical speed, and after 48 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com