Water-soluble minimum quantity lubricating liquid containing MoS2

A minimal quantity lubrication, water-soluble technology, applied in the direction of lubricating composition, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as inapplicability, large particle size, and difficulty in following lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

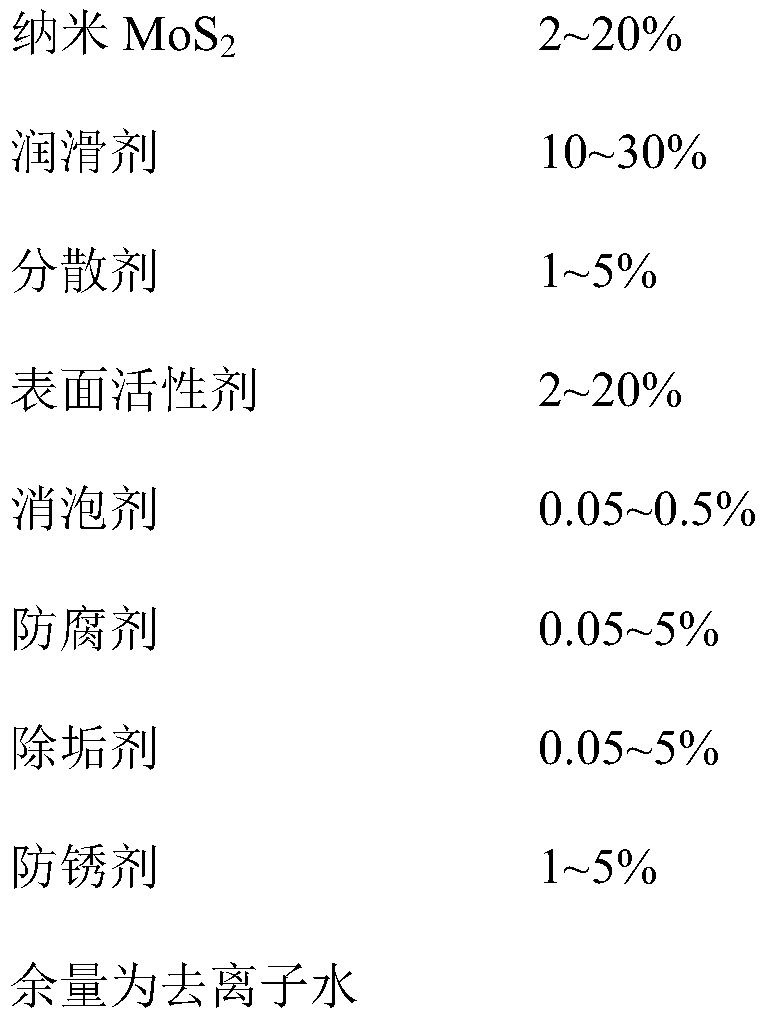

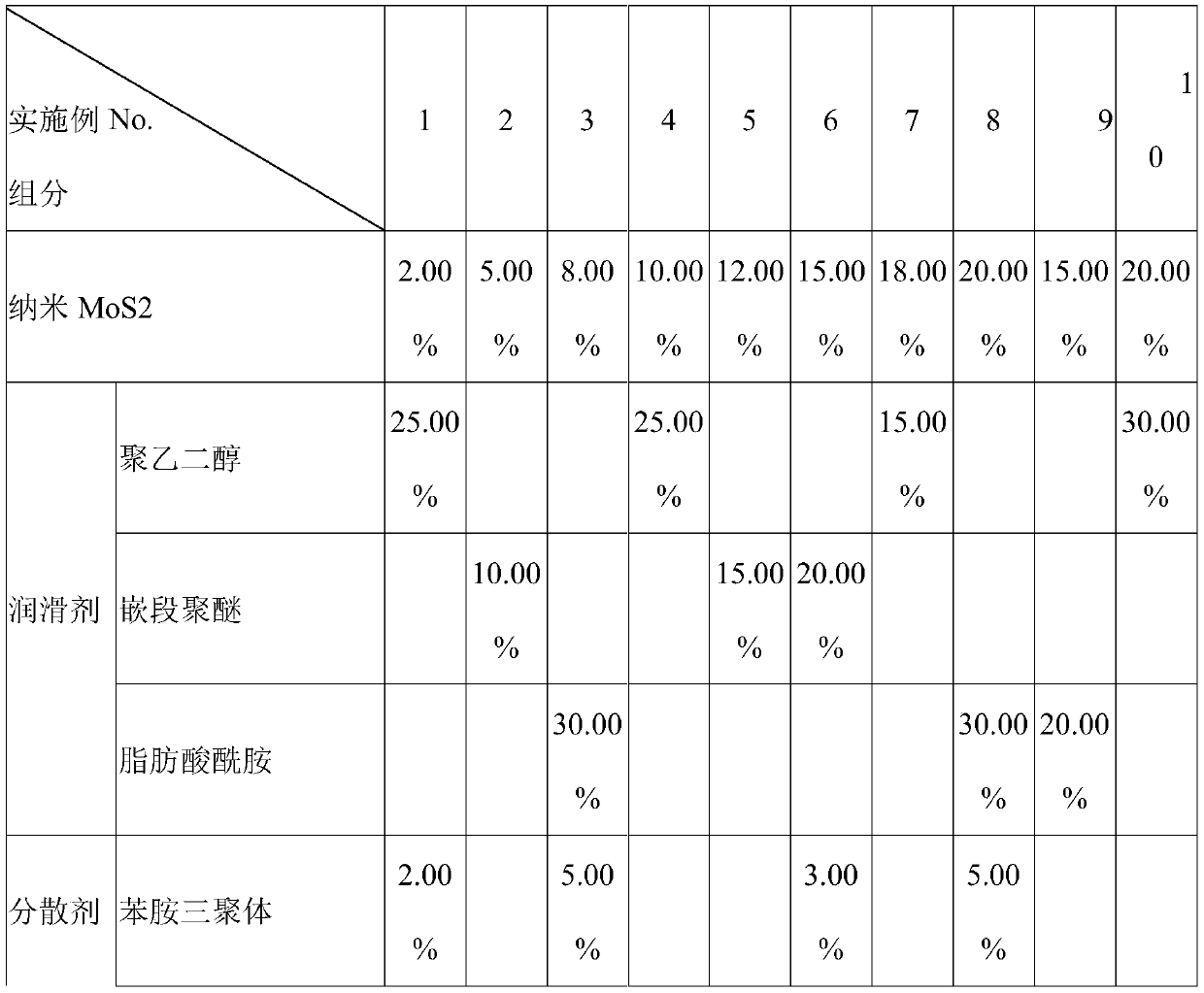

[0049] The invention provides a MoS-containing 2 The water-soluble micro-lubricating fluid comprises each component according to the weight percent of Example 1 in the above Table 1.

[0050] Among them, nano-MoS 2 The preparation method comprises the steps:

[0051] (1) Mix the prepared ammonium molybdate solution and ammonium sulfide solution in a three-necked flask with a molar ratio of 1:5, and use 95% ethanol as a dispersant and a surfactant;

[0052] (2) Put it in a constant temperature water bath at 90°C, drop hydrochloric acid into the mixed solution under continuous stirring conditions, make it evenly mixed and fully react;

[0053] (3) After the reaction is finished, filter the precipitate to obtain a brown paste precipitate, and then repeatedly wash the precipitate;

[0054] (4) Make a suspension with absolute ethanol, put it in a drying oven at 60°C and dry it for 6 hours to obtain molybdenum trisulfide;

[0055] (5) Grind the dried molybdenum trisulfide into f...

Embodiment 2-10

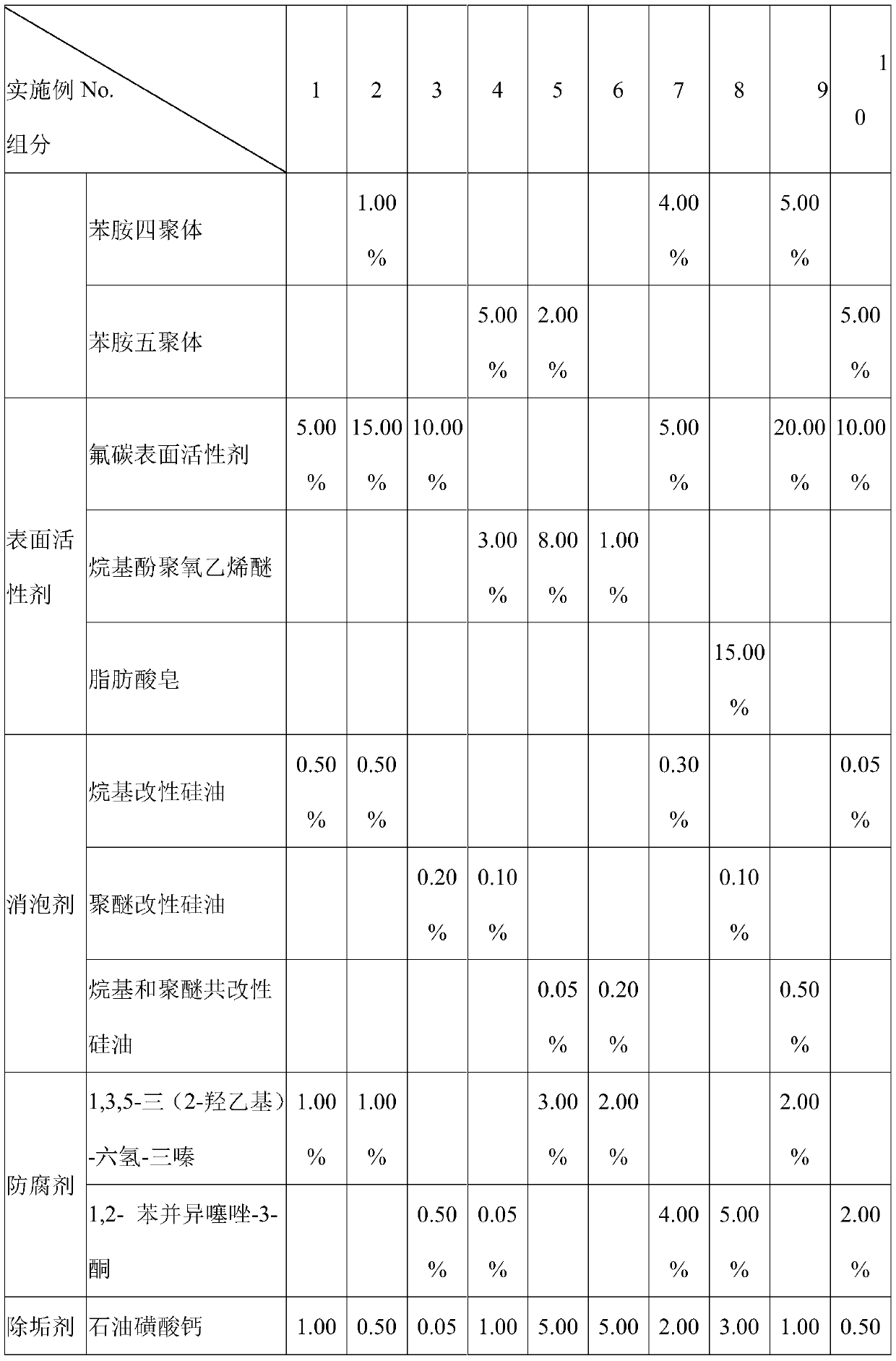

[0063] Each of Examples 2-10 contains MoS 2 The water-soluble micro-lubricating fluid comprises the components in the weight percentage of Examples 2-10 in the above Table 1, and the nano-MoS used 2 The preparation method and the preparation method of the water-soluble micro-lubricating fluid are consistent with those in Example 1.

[0064] Containing MoS for Examples 1-10 2 The method, procedure, and evaluation of the physical properties of the water-soluble microlubricating fluid are carried out in accordance with the standard GB / T6144-2010, and the results are shown in Table 2.

[0065] Table 2 MoS of Examples 1-10 2 Evaluation results of physical properties of water-soluble microlubricating fluid

[0066]

[0067] According to the above experimental data, the appearance, defoaming properties, surface tension and rust resistance of the water-based cutting fluids in Examples 1-7 all conform to the national standard of GB / T6144-2010.

[0068] In summary, the MoS-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com