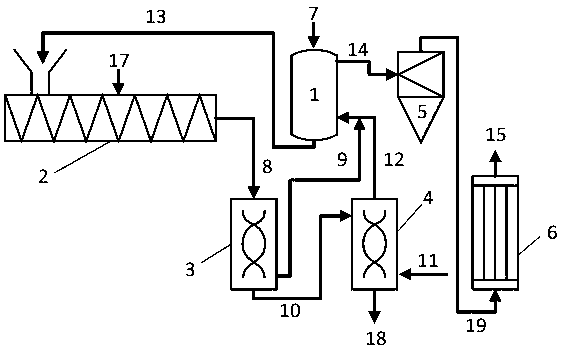

Biomass microwave pyrolysis gasification method and system

A technology of pyrolysis gasification and biomass, applied in gasification process, gasification catalyst, waste fuel, etc., can solve the problems of poor quality and low synthesis gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

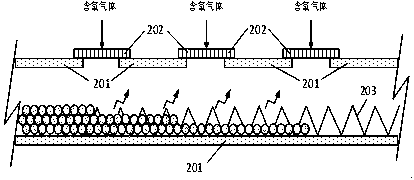

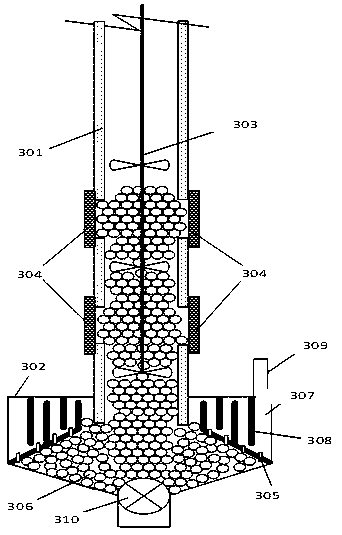

[0093] Preparation of ceramic filter membranes used in the system of the present invention:

[0094]According to the mass percentage, 5% nickel oxide, 5% titanium oxide, and 90% olivine are fully mixed to prepare coating powder. First, 1.5 parts of coating powder are mixed with acrylic acid to obtain acidic coating powder. Among them, the acidic coating powder is coated with Layer powder mass percentage is 90%, pore-forming agent mass percentage is 10%; Then get 1 part of coating powder and urea and mix to obtain alkaline coating powder, wherein the coating powder mass percentage in the basic coating powder is 90%, The mass percentage of the pore-forming agent is 10%; the acidic coating powder and the basic coating powder obtained above are prepared into a slurry with water according to the volume ratio of 3:1, and after 6 hours of ball milling, the pore size of 20-100nm is obtained. Acidic and alkaline coating slurry, then the multi-channel ceramic membrane soaked in ethanol ...

Embodiment 2

[0096] According to the mass percentage, 5% nickel oxide, 10% iron oxide, 10% titanium oxide, 20% aluminum oxide and 55% olivine are fully mixed to prepare coating powder. Firstly, 3 parts of coating powder are mixed with acrylic acid to obtain an acidic coating. layer powder, wherein the mass percentage of coating powder in the acidic coating powder is 90%, and the mass percentage of pore-forming agent is 10%; then get 1 part of coating powder and urea to mix to obtain alkaline coating powder, wherein The mass percentage of the middle coating powder is 90%, and the mass percentage of the pore-forming agent is 10%; the acidic coating powder and the basic coating powder obtained above are respectively mixed with water according to the volume ratio of 2:1 to prepare a slurry, and after 6 After hours of ball milling, 20-100nm acidic and alkaline coating slurries were obtained, and then the multi-channel ceramic membrane soaked in ethanol (pore diameter 50nm, porosity 48%, length 6...

Embodiment 3

[0098] According to the mass percentage, 25% aluminum oxide, 5% iron oxide, 2.5% titanium oxide, 5% nickel oxide, 62.5% olivine are fully mixed to prepare coating powder. layer powder, wherein the mass percentage of coating powder in the acidic coating powder is 90%, and the mass percentage of pore-forming agent is 10%; then get 1 part of coating powder and urea to mix to obtain alkaline coating powder, wherein The mass percentage of the middle coating powder is 90%, and the mass percentage of the pore-forming agent is 10%; the acidic coating powder and the basic coating powder obtained above are respectively mixed with water in a volume ratio of 1:1 to prepare a slurry, and after 6 After hours of ball milling, 20-100nm acidic and alkaline coating slurries were obtained, and then the multi-channel ceramic membrane soaked in ethanol (pore diameter 50nm, porosity 48%, length 600mm, outer diameter 40mm, each multi-channel Ceramic membrane area 0.5m 2 ) into the acidic slurry for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com