Force-induced responsive polymer with single hybrid network structure

A network structure and polymer technology, applied in the field of mechanoresponsive polymers, can solve problems such as inability to effectively prevent expansion, non-responsive mechanical force, and poor material toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

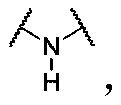

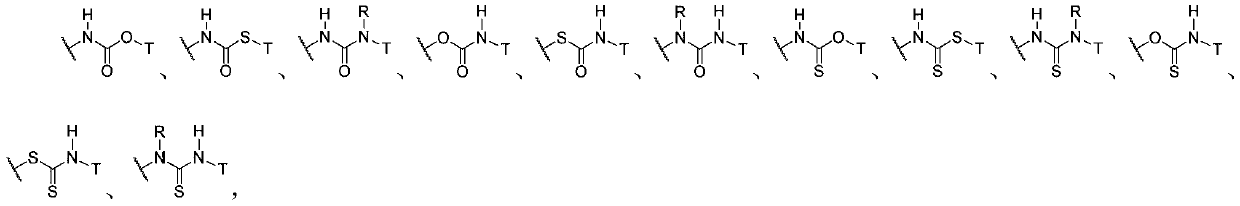

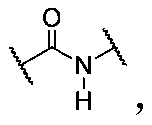

Method used

Image

Examples

Embodiment approach

[1917] In the present invention, the mechanoresponsive polymer may have one, two or more than two glass transition temperatures, or may not have a glass transition temperature. Among them, in a preferred embodiment of the present invention, at least one of the glass transition temperatures of the mechanoresponsive polymer is higher than 100°C, more preferably all of them are higher than 100°C, and the size of the resulting mechanoresponsive polymer Stability, mechanical strength, and high temperature resistance are good, and are suitable for application scenarios with high requirements for stress bearing and rigidity; in another preferred embodiment of the present invention, the glass transition temperature of the mechanoresponsive polymer is at least One of them is between 25 and 100°C, more preferably all of them are between 25 and 100°C, which is convenient for preparing polymer products in the form of ordinary solids, foams, and gels above room temperature, and is suitable ...

Embodiment 1

[1934]

[1935] Toluene is used as solvent, hydrogen-containing polysiloxane (a) (40% silicon-hydrogen bond content) and 4-acrylamidobutyric acid are used as raw materials, and xylene solution of Karstedt catalyst is used as catalytic system, and stirred at 85°C After 10 hours of reaction, polysiloxane (b) was obtained. Take 0.2 molar equivalents of polysiloxane (b) and 5 molar equivalents of compound (c), place them in a reaction vessel, dissolve them with an appropriate amount of dichloromethane, then add 25 molar equivalents of diisopropylcarbodiimide, 2.5 molar equivalents 4-Dimethylaminopyridine, stirred and reacted at room temperature for 16 hours, after the reaction was completed, impurities and solvents were removed to obtain a purified product; 15 g of the obtained product was swollen in 100 mL of ethanol, and then 20 mL of 0.2 g / mL zinc dichloride was added dropwise under stirring After the dropwise addition, 10 mL of triethylamine was added, stirred at room tempe...

Embodiment 2

[1937]

[1938] Using triethylamine as a catalyst and dichloromethane as a solvent, react compound (a) with excess acryloyl chloride to prepare diacrylate (b); take 5 molar equivalents of compound (b), 90 molar equivalents of compound (c ), 25 molar equivalents of compound (d), and 0.2 molar equivalents of AIBN were placed in a reaction vessel, dissolved with an appropriate amount of toluene, and then stirred and reacted at 70°C for 24 hours under a nitrogen atmosphere. After the reaction was completed, the product was placed in a mold, and Dry in a vacuum oven at 100°C for 6 hours, and then slowly cool down to room temperature to obtain a common solid polymer. Gradient changes in the mechanical strength and modulus of the polymer can be achieved by controlling the incident light intensity and the irradiation position, so that the polymer can have a gradual mechanochromic effect under the same mechanical force, which can be used as a stress warning Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com