Special formula of grinding wheel for grinding automobile piston ring

An automobile piston and grinding wheel technology, applied in the grinding wheel field, can solve the problems of low service life of the grinding wheel, inability to adapt at the same time, and low overall quality of the grinding piston ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

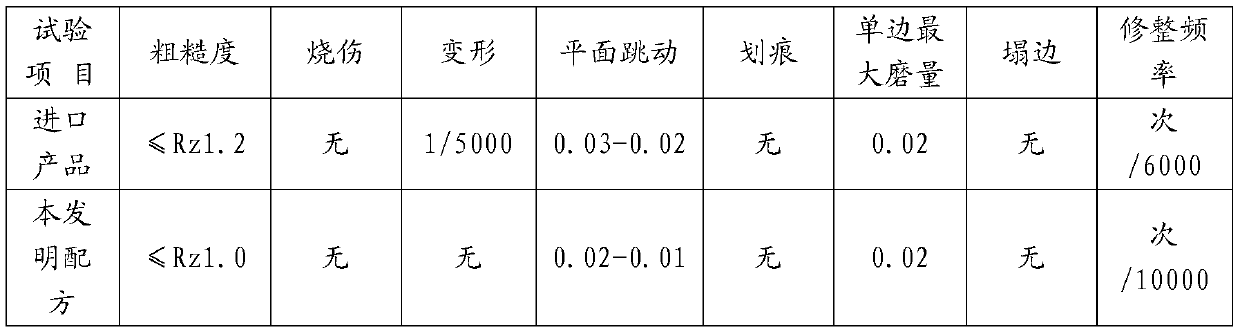

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment.

[0009] A special formula for grinding automobile piston ring grinding wheel, the main abrasive composition is as follows:

[0010] Abrasive composition formula table (the percentage of each abrasive to the total volume of the abrasive)

[0011] Abrasive name Abrasive size Percentage of the total volume of the abrasive % 41CC F220 45 SSA F220 25 32A F240 10 CA F240 20

[0012] According to the characteristics of the double-end grinding method used in piston ring processing, which is not easy to dissipate heat, and the grinding fluid is water-based and oil-based, a special binder formula is designed, and its binding force to the abrasive is controlled within a certain range, so that the grinding wheel It is resistant to aging and has a certain grinding force. Its binder formula is as follows:

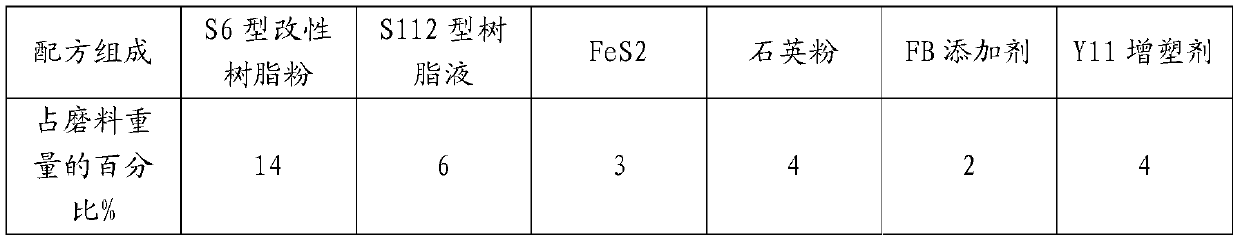

[0013] Binder formula composition table

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com