Rice bran powder and processing method thereof

A processing method and rice bran powder technology, applied in the field of rice bran powder and its processing, can solve the problems of unfavorable nutrient absorption, reduced nutrient content, and relatively destructive nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

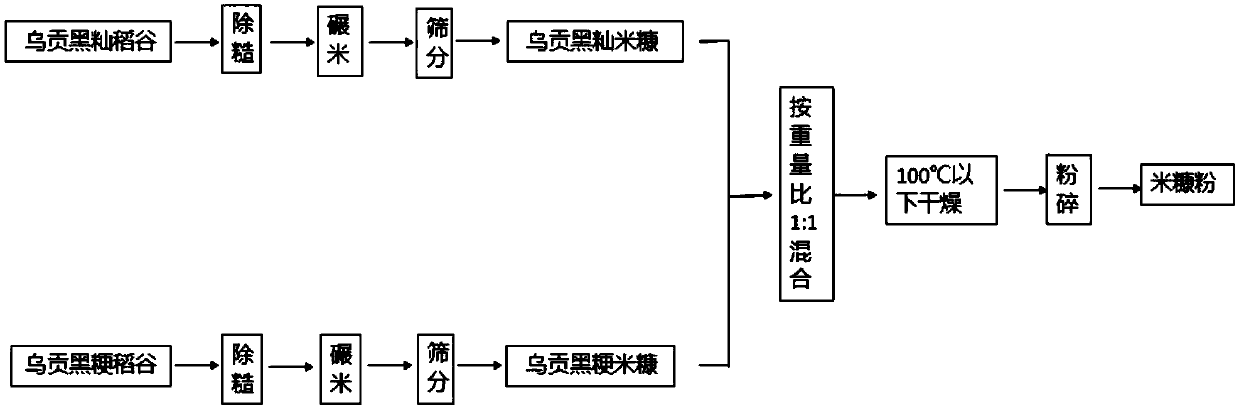

[0035] This embodiment is based on figure 1 Raw material rice was preliminarily processed as indicated, and Wugong black indica rice (purchased from Shanghai Shangnong Health Food Co., Ltd.) Brown and milled rice. Among them, dehusking is the process of removing the husks of paddy rice to obtain brown rice. Rice milling is the process of stripping the bran and grain of brown rice. However, a small amount of broken rice is mixed in the rice bran collected after peeling, and the rice bran containing a small amount of broken rice is called a rice bran mixture. It is then sieved using a vibrating sieve. The sieve hole size of the vibrating sieve is 20 mesh, and the rice bran or the rice bran mixture with a rice bran content of 70% is obtained through sieving. The vibrating screen is made of copper or stainless steel.

[0036] In this embodiment, the rice bran or the rice bran mixture is dried. The drying equipment is an electronic intelligent drying equipment that can contro...

Embodiment 2

[0042] This embodiment is based on figure 1 Raw material rice was preliminarily processed as indicated, and Wugong black indica rice (purchased from Shanghai Shangnong Health Food Co., Ltd.) Brown and milled rice. Among them, dehusking is the process of removing the husks of paddy rice to obtain brown rice. Rice milling is the process of peeling off the bran and grain of brown rice, but a small amount of broken rice is mixed in the rice bran collected after peeling, and the rice bran containing a small amount of broken rice is called a rice bran mixture. Then use a vibrating sieve to sieve. The mesh size of the vibrating sieve is 26 meshes, and the rice bran or the rice bran mixture with a rice bran content of 60% is obtained through sieving. The vibrating screen is made of copper or stainless steel.

[0043] In this embodiment, the rice bran or the rice bran mixture is dried. The drying equipment is an electronic intelligent drying equipment that can control temperature a...

Embodiment 3

[0049] The rice bran powder in this example is made from the rice bran of Wugong black indica brown rice and Wugong black japonica brown rice. The weight ratio of Ugon black indica rice bran and Ugon black japonica rice bran is 1:1. The resulting rice bran powder contained 7.4% (weight percent) anthocyanins. 10.6% (by weight) of the crude fiber in the original state remained in the rice bran powder. Rice bran powder also preserves 352mg / kg calcium, 71.1mg / kg iron, 58mg / kg zinc, 101mg / kg vitamin E and 1mg / kg vitamin B1. The content of total flavonoids in rice bran powder is 2510mg / kg. The starch content in the rice bran powder is 300 g / kg, the water content of the rice bran powder is 113 g / kg, and the fineness of the rice bran powder is below 200 mesh, preferably 200 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com