Jasmine flower fragrant rice and processing method and device

A processing method and technology of a processing device are applied in the directions of food ingredients as odor modifiers, functions of food ingredients, food ingredients containing natural extracts, etc., and can solve the problems of complex production operation of fragrant rice, waste of raw materials of jasmine flowers, long production time and other problems. , to achieve the effect of saving equipment cost, reducing fragmentation and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

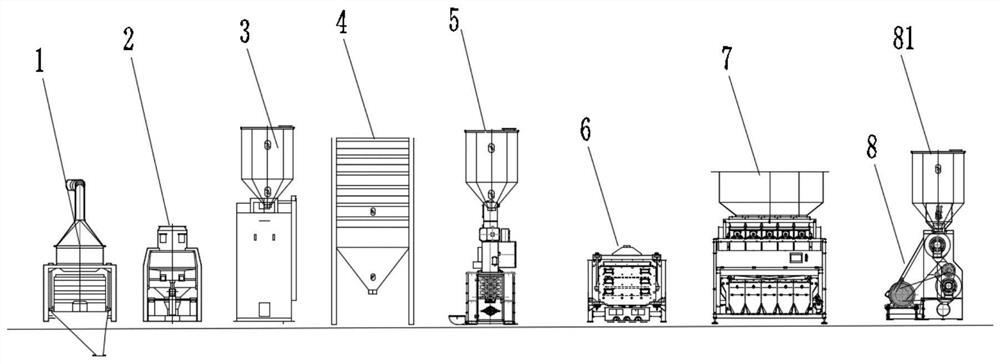

Image

Examples

Embodiment 1

[0072] The processing method of the jasmine fragrant rice described in the present embodiment, comprises carrying out following steps successively:

[0073] S1. Select clean organic rice, use drum initial cleaning sieve and vibrating sieve to carry out preliminary cleaning of rice, and remove weeds, branches and leaves in rice;

[0074] S2. Use a destoner to remove the soil and gravel mixed in the rice;

[0075] S3. Adopt magnetic separator to remove the iron-containing impurities mixed in the paddy;

[0076] S4. Use a six-layer circulation dryer to dry the paddy until the moisture content is 10%-15%;

[0077] S5. Using a huller to dehull the paddy to obtain hulled rice with a husking rate > 85%;

[0078] S6. Use a separation sieve to separate the complete grains of the hulled rice from the incomplete grains, and select the complete grains for standby;

[0079] S7. The complete rice grains will be selected, and the color sorter will be used to remove the different-colored g...

Embodiment 2

[0086] The processing method of the jasmine fragrant rice described in the present embodiment, comprises carrying out following steps successively:

[0087] S1. Select clean organic rice, use drum initial cleaning sieve and vibrating sieve to carry out preliminary cleaning of rice, and remove weeds, branches and leaves in rice;

[0088] S2. Use a destoner to remove the soil and gravel mixed in the rice;

[0089] S3. Adopt magnetic separator to remove the iron-containing impurities mixed in the paddy;

[0090] S4. Use a six-layer circulation dryer to dry the paddy until the moisture content is 10%-15%;

[0091] S5. Using a huller to dehull the paddy to obtain hulled rice with a husking rate > 85%;

[0092] S6. Use a separation sieve to separate the complete grains of the hulled rice from the incomplete grains, and select the complete grains for standby;

[0093] S7. The complete rice grains will be selected, and the color sorter will be used to remove the different-colored g...

Embodiment 3

[0098] The processing method of the jasmine fragrant rice described in the present embodiment, comprises carrying out following steps successively:

[0099] S1. Select clean organic rice, use drum initial cleaning sieve and vibrating sieve to carry out preliminary cleaning of rice, and remove weeds, branches and leaves in rice;

[0100] S2. Use a destoner to remove the soil and gravel mixed in the rice;

[0101] S3. Adopt magnetic separator to remove the iron-containing impurities mixed in the paddy;

[0102] S4. Use a six-layer circulation dryer to dry the paddy until the moisture content is 10%-15%;

[0103]S5. Using a huller to dehull the paddy to obtain hulled rice with a husking rate > 85%;

[0104] S6. Use a separation sieve to separate the complete grains of the hulled rice from the incomplete grains, and select the complete grains for standby;

[0105] S7. The complete rice grains will be selected, and the color sorter will be used to remove the different-colored gr...

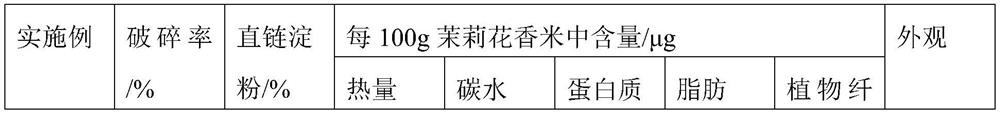

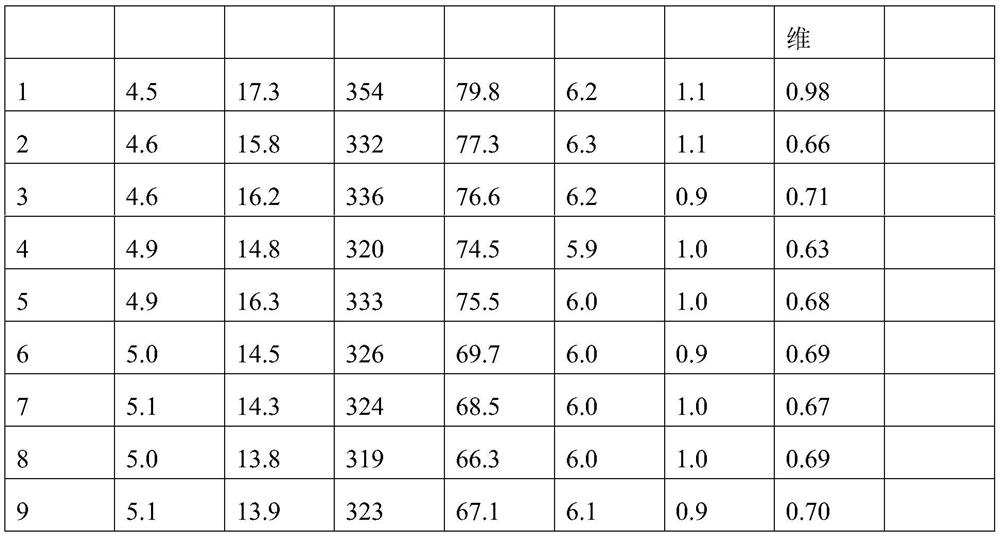

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com