Prefabricated reinforced concrete side anti-collision guardrail connected with bridge, and construction method thereof

A technology of reinforced concrete and connecting steel bars, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of very high installation accuracy of sleeves, affect the safety performance of guardrails, and large cast-in-place space for bridge decks, so as to reduce the overall overturning The risk, simple structure, and the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

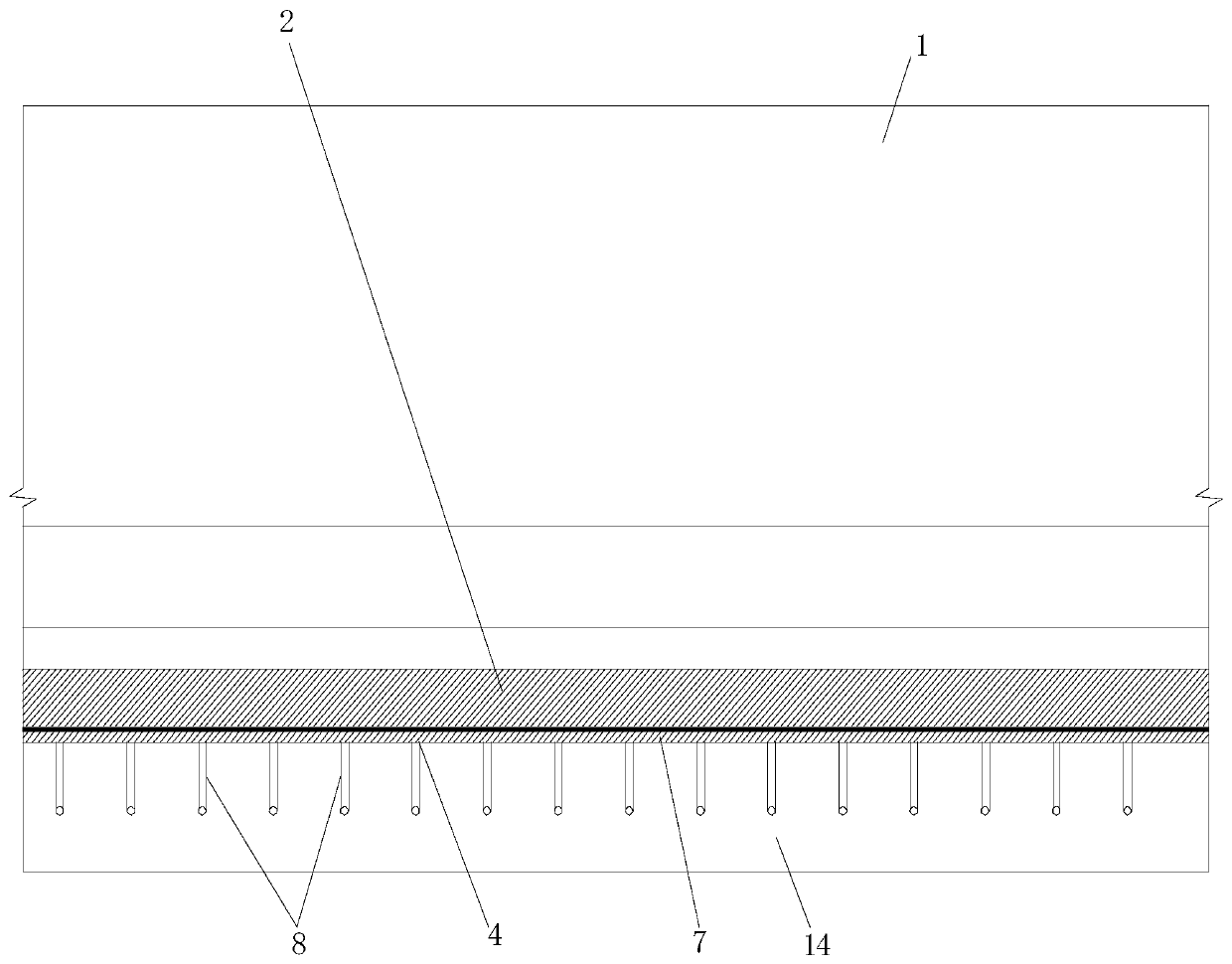

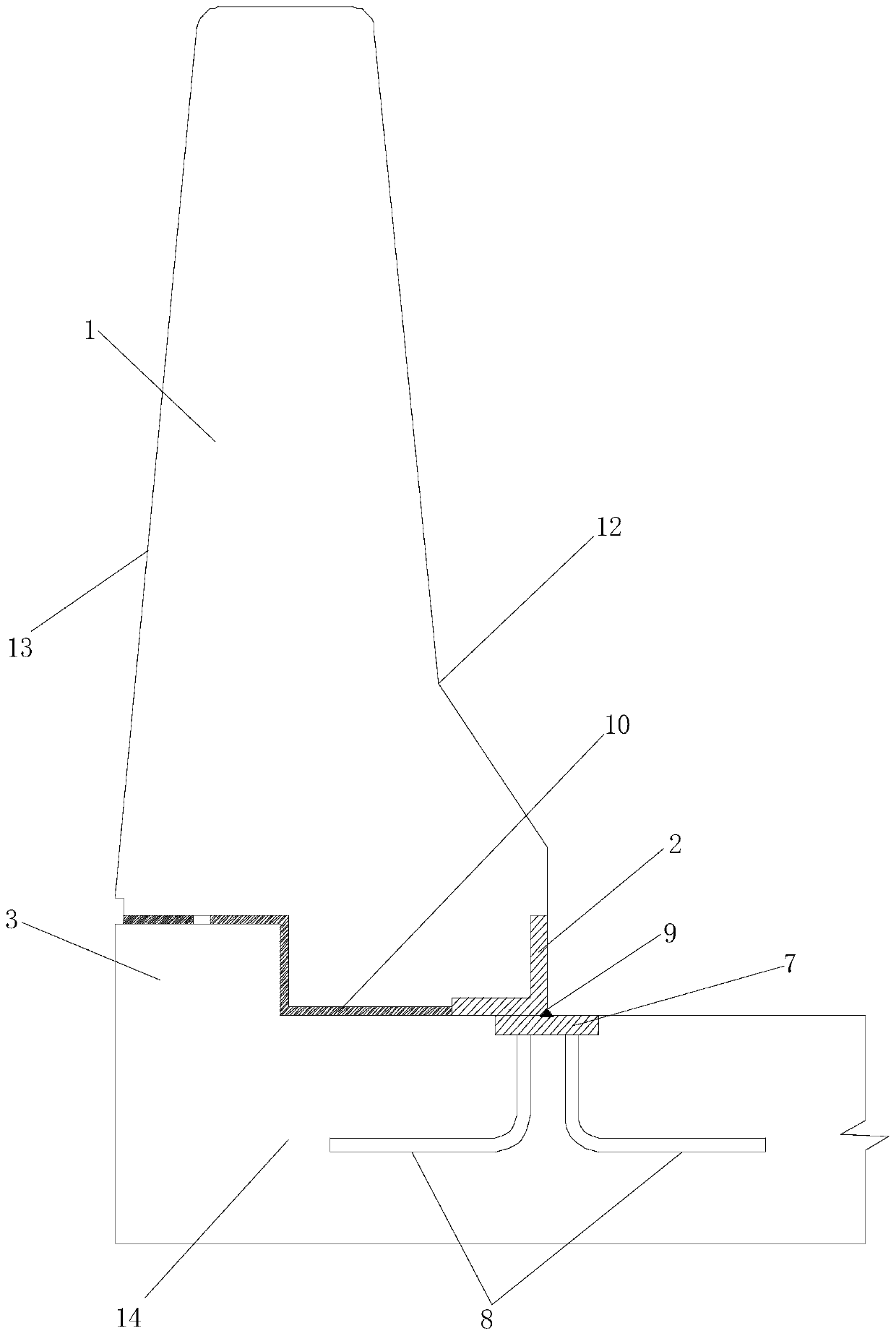

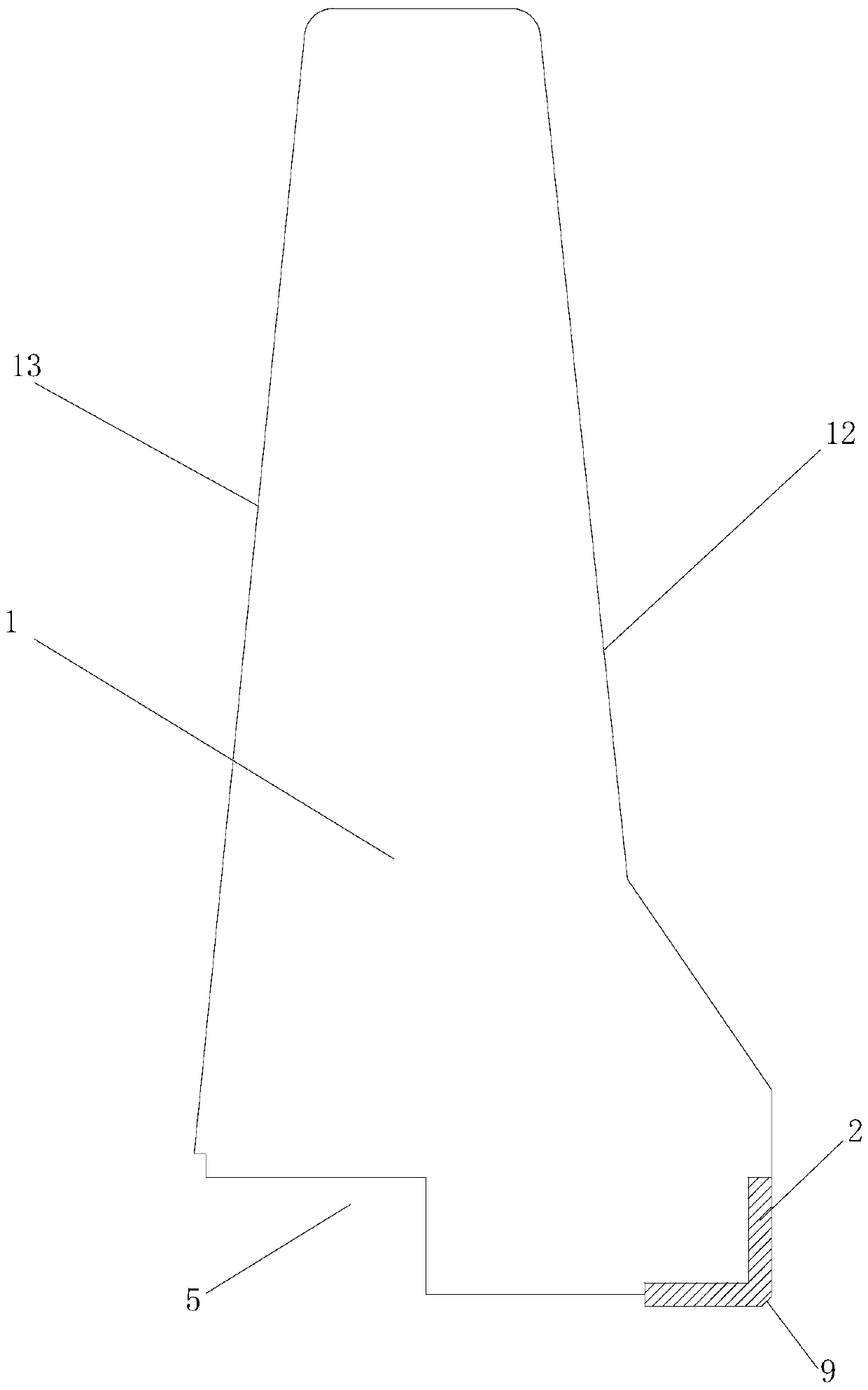

[0046] Such as Figure 1 to Figure 5The assembled reinforced concrete side crash guardrail connecting the bridge shown includes guardrails, angle steel, stoppers fixed on the bridge deck and pre-embedded parts embedded in the bridge. The two sides of the guardrail are facing The collision surface and the back collision surface, the lower end of the guardrail is provided with an embedding groove, and the embedding groove is clamped to the stopper; the bottom surface between the embedding groove and the collision surface of the guardrail and the collision surface of the guardrail The lower ends of each are equipped with connecting reinforcement, which is welded to the two inner sides of the angle steel; the embedded parts include steel plates and curved embedded reinforcement, the embedded reinforcement is fixed in the bridge, and the steel The upper end of the steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com