Method for calculating resistivity of residual materials in continuous drawing single crystal rod pot

A calculation method and resistivity technology, which is applied in the field of calculation of the resistivity of the remaining material in the pot for continuous drawing of single crystal ingots, and can solve the problems of affecting the yield rate, large deviation in resistivity estimation, scrapped head resistivity at the tail, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as drawing phosphorus-doped N-type single crystal, the segregation coefficient is 0.38, and the method for calculating the resistivity of the material in the pot by the method of the present invention and the confirmation process of the calibration coefficient a are as follows:

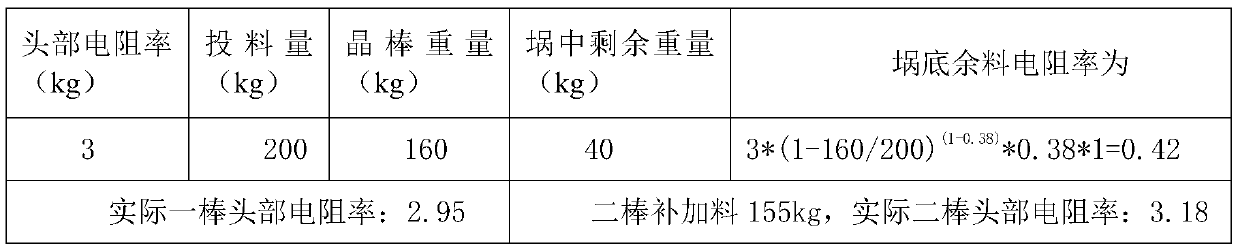

[0037] 1. The first furnace: the first rod and the second rod are drawn by casting pure polycrystalline, the resistivity of the remaining material in the crucible of the first rod is calculated according to formula 1, the default calibration coefficient a=1, and the resistivity of the head is controlled by 3, as follows surface:

[0038]

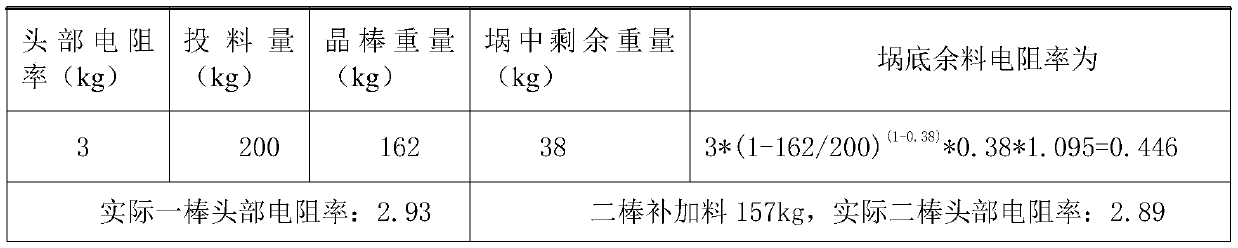

[0039] The difference in the actual head resistivity of the two rods is farther from the setting than that of the first rod. Because the cast is pure polycrystalline, the difference in the resistivity of the two rods is mainly caused by the inaccurate resistivity of the material in the remaining crucible. Use the actual resistance of the second rod Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com