Columnar workpiece paint spraying device for machining

A columnar workpiece, machining technology, applied in spray devices, liquid spray devices, spray booths, etc., can solve the problems of insufficient spray paint, inconvenient operation, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

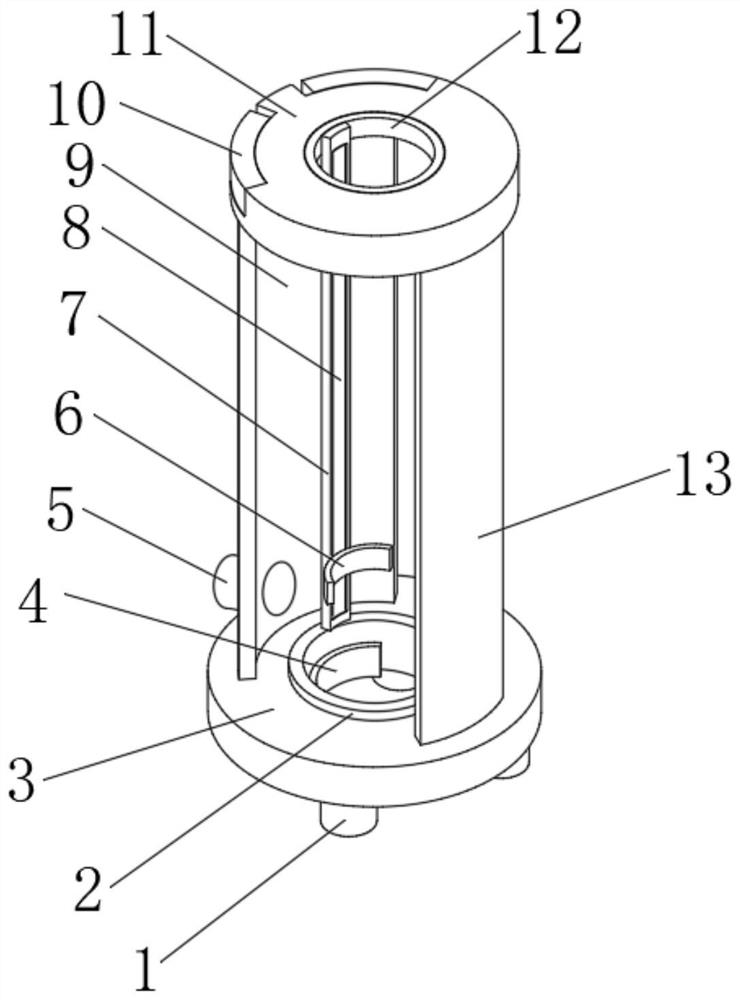

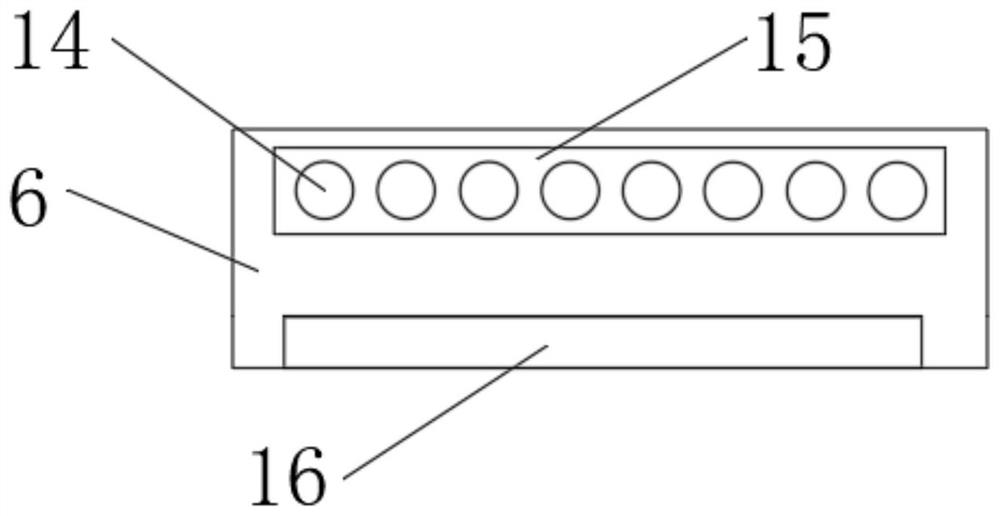

[0027] refer to Figure 1-4 , a columnar workpiece painting device for mechanical processing, comprising a first annular support plate 3 and a second annular support plate 11, the outer wall of the top side of the first annular support plate 3 is connected with an arc-shaped groove plate 9 by bolts, and the arc-shaped The top outer wall of the slot plate 9 is connected with the bottom side outer wall of the second annular support plate 11 by bolts, and the bottom outer wall of the arc slot plate 9 side is connected with the discharge pipe 5 by bolts, the second annular support plate 11 and the first The outer walls at both ends of one side of the annular support plate 3 are provided with first grooves, and the ends of the four first groove inner walls that are far away from each other are connected with support legs 10 through hinges, and the inner wall of the ring mouth of the second annular support plate 11 passes through An annular electric guide rail 12 is connected by bol...

Embodiment 2

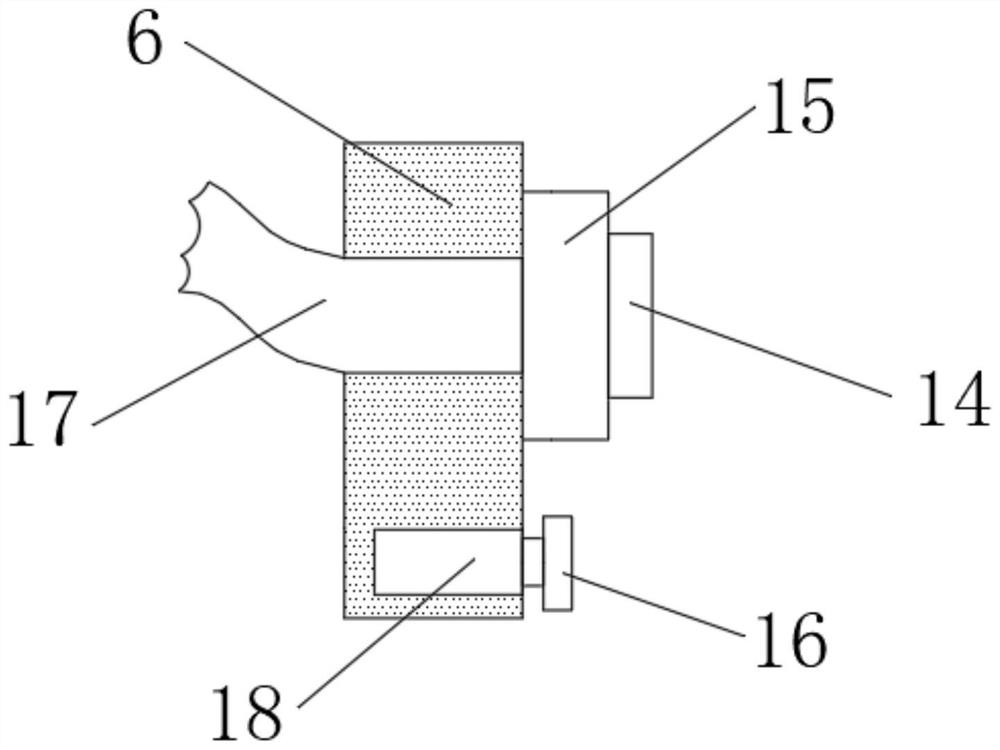

[0035] refer to Figure 1-5 , a columnar workpiece painting device for mechanical processing, also includes a rotating rod 23 installed horizontally on the inner wall of the liquid spray pipe 14 through bearings, and the outer wall of the middle part of the rotating rod 23 is connected with a sheave 22 by bolts.

[0036] Working principle: when in use, by setting the rotating rod 23 and the sheave 22 in the liquid spray pipe 14, the sheave 22 can roll on the columnar workpiece, which reduces the frictional force and ensures that the liquid spray pipe 14 is compatible with the columnar workpiece. The close proximity of the workpiece improves the adequacy of the painting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com