Chain machining method for uniform paint coating of chains

A processing method and chain technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of uneven paint on the chain, easy to produce defective products, etc., achieve sufficient paint, reduce waste, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

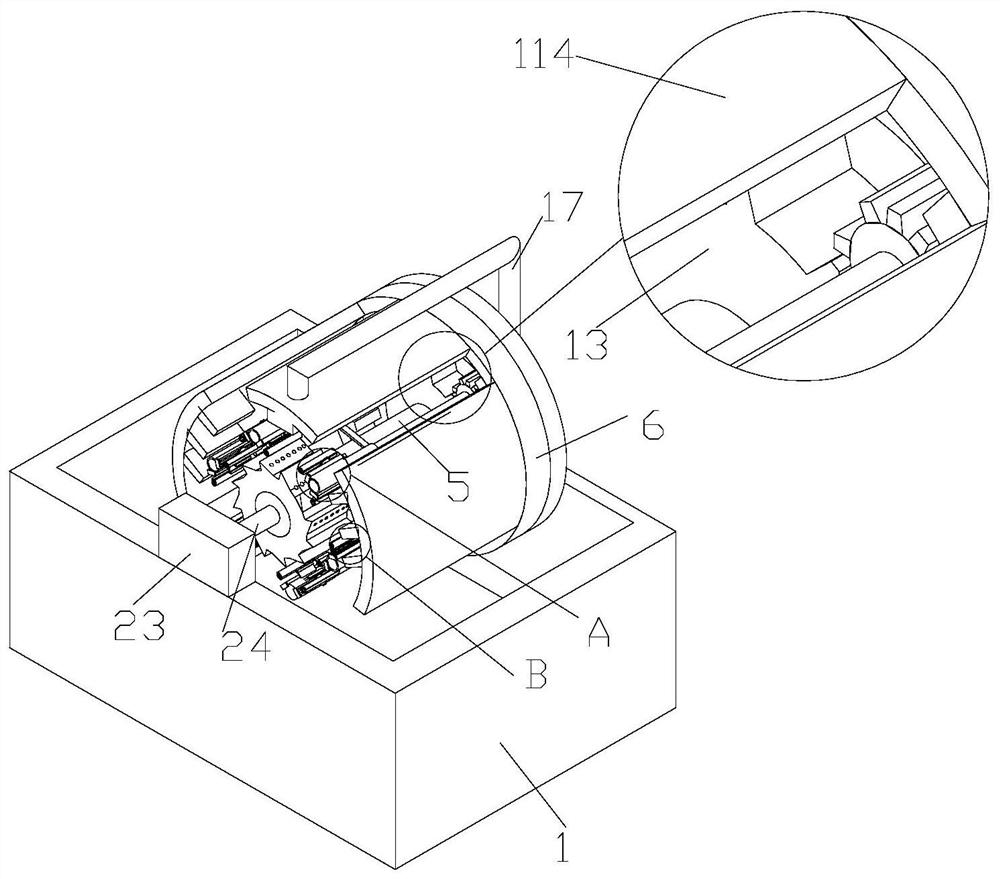

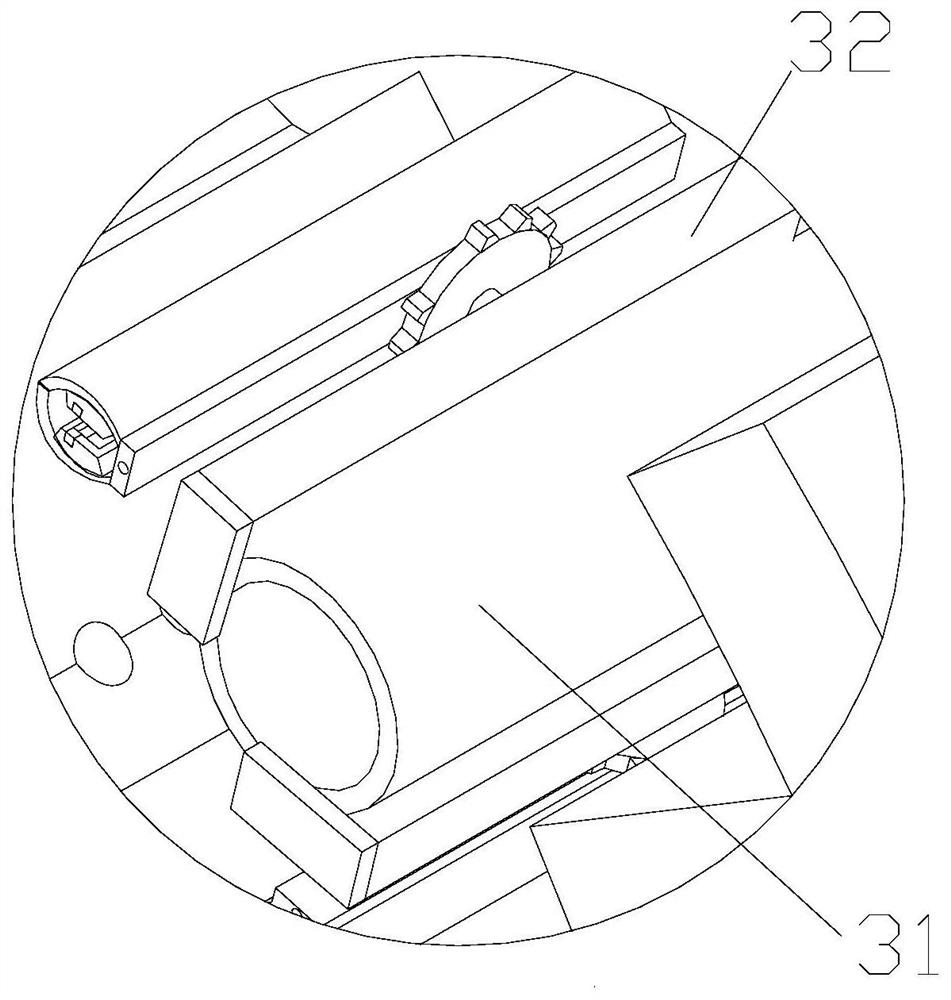

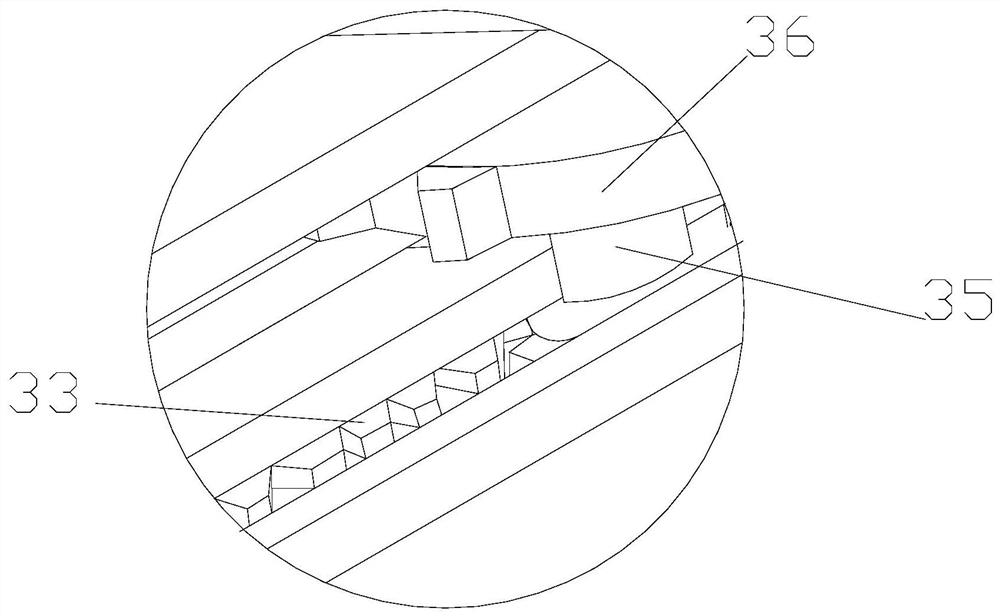

[0039] A chain processing method for evenly painting the chain, the steps of the processing method can be divided into:

[0040] In order to achieve the above object, the present invention adopts the following technical solutions: a chain processing method for evenly painting the chain, comprising the following steps:

[0041] a. Assembly: Assemble the inner chain plate, outer chain plate, sleeve, pin shaft and roller into a chain;

[0042] b. Heat treatment: put the assembled chain into heat treatment equipment for heat treatment;

[0043] c. Shot peening: Use shot peening equipment to spray steel shot on the surface of the chain to form small pits;

[0044] d. Painting; use chain painting equipment to paint the chain;

[0045] e. Drying: use baking equipment to dry the painted chain;

[0046] The heat treatment includes carburizing, quenching, tempering, blackening, and bluing.

[0047] The paint components in the varnish include oil, resin, pigment and thinner.

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com