Preparation method and preparation equipment of shell water-based coating material taking mesh macromolecules as film-forming material

A film-forming material, water-based paint technology, applied in the field of paint, can solve the problems of volatile, fire, hazardous chemical components, etc., and achieve the effect of reducing formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

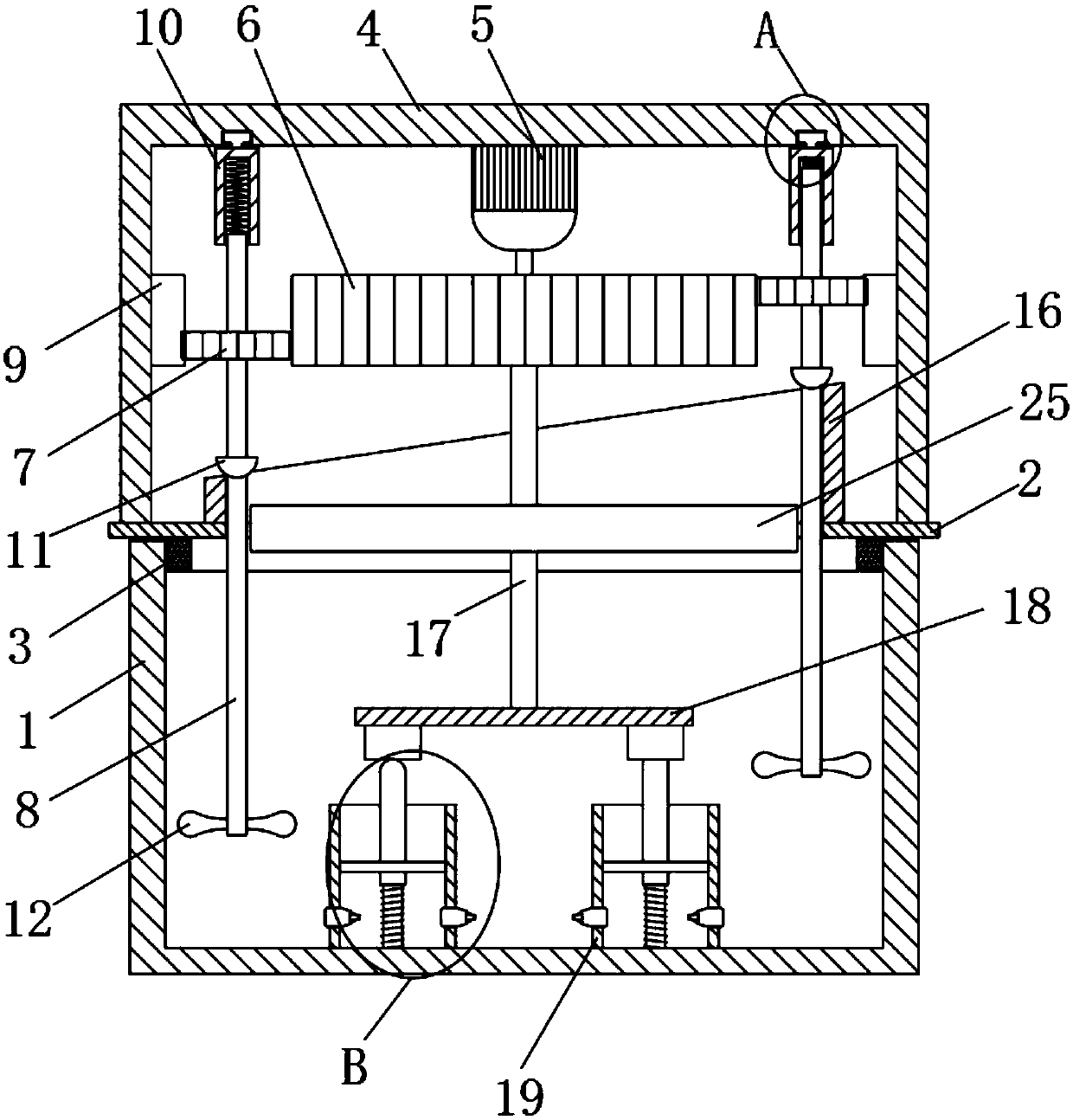

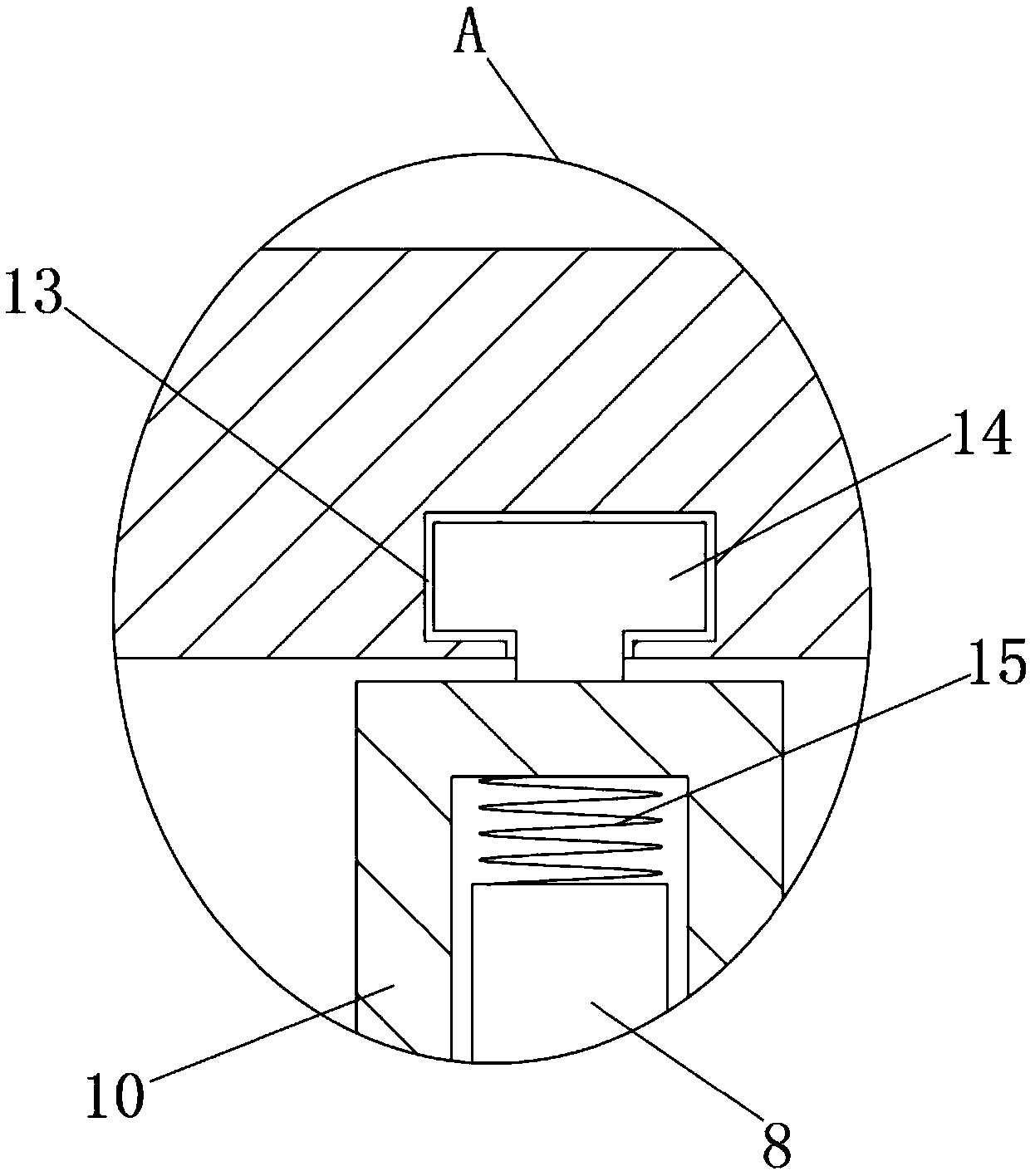

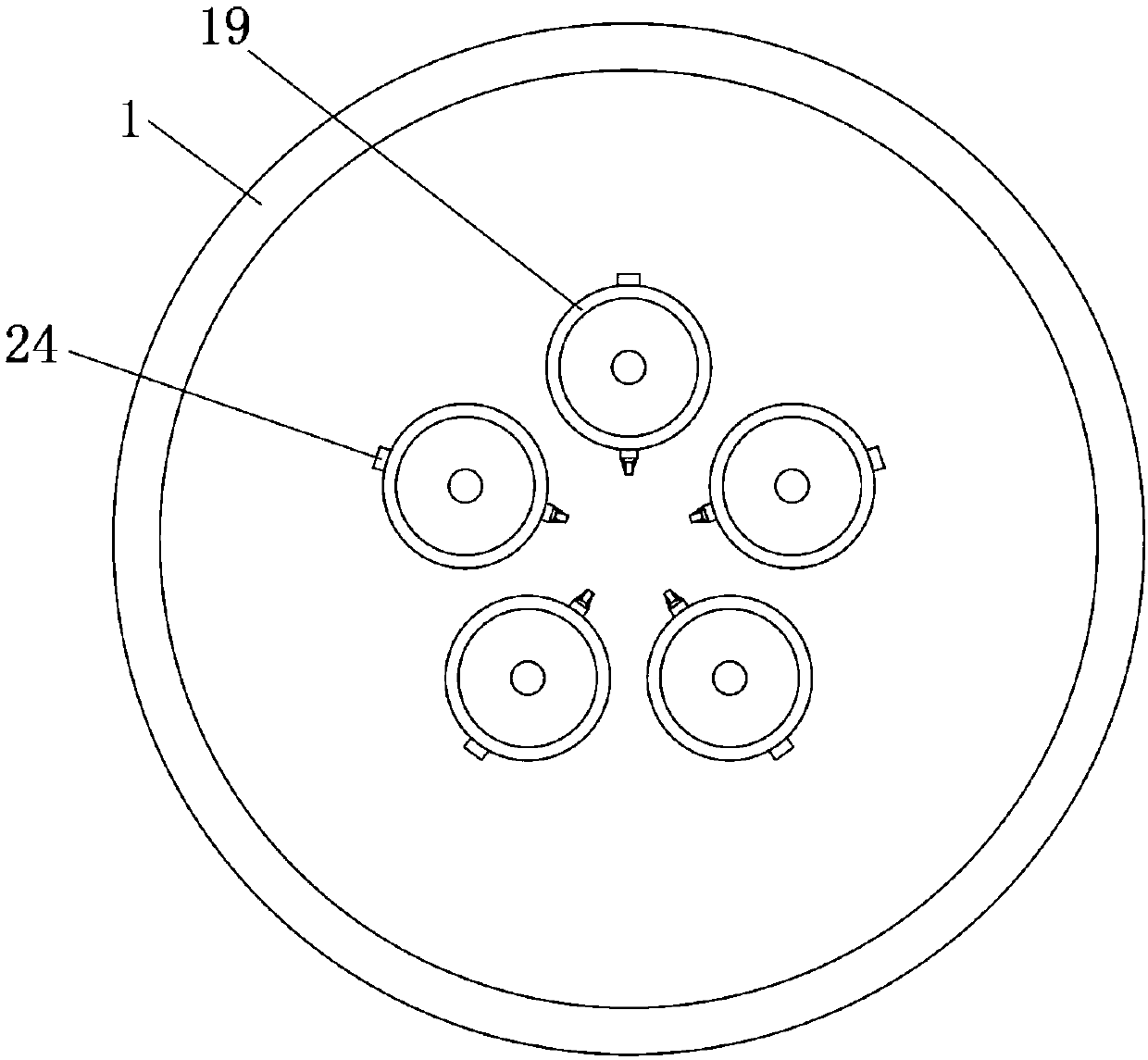

Image

Examples

Embodiment

[0033] A kind of preparation method of the shell water-based coating that takes mesh macromolecule as film-forming material, comprises the following steps:

[0034] S1: Put the dispersant, shell powder and deionized water in a container with a stirring device, perform mechanical stirring for 1 to 2 hours, add fillers in corresponding parts by weight, and continue stirring for 30 to 60 minutes to obtain a mixture;

[0035] S2: Add the corresponding weight portion of mesh film-forming material to the mixture, continue to stir for 15-20 minutes, disperse evenly and sieve to obtain the finished product.

[0036] The parts by weight of the above-mentioned ingredients are as follows: 2-8 parts of dispersant, 70-95 parts of shell powder, 80-100 parts of filler, 2-10 parts of mesh film-forming material, and 20-60 parts of deionized water;

[0037] The above-mentioned fillers include the following ingredients by weight: 26-28 parts of polyacrylate, 27-30 parts of isocyanate, 26-29 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com