Cathode charcoal block set specific resistance measuring method

A cathode carbon block and measurement method technology, applied in the field of aluminum electrolysis, can solve the problems of poor reliability of detection data, long detection distance, and few detection points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

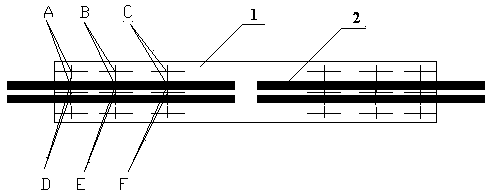

[0044] The specific technical solution of the measuring method of the present invention is: (1) Selection of the measuring position. When used in the electrolytic cell, the current is from the surface of the cathode carbon block to the cathode steel rod through the assembled bottom pad and vertical seam, and then from the cathode steel rod to the bus bar. The specific resistance of the carbon block group is the best choice. From the perspective of fracture mechanics, materials that appear to be very sound on the surface hide many cracks that are so small that the naked eye cannot detect them under the detection of modern flaw detection technology. Since there are cracks, it is clear that the cracks will affect the measured value. In order to reduce this error, the best way is to narrow the measurement interval. Therefore, the measurement position should be selected on the bottom surface of the cathode carbon block; (2) Selection of measurement distance. According to the vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com