Impedance measurement-based PC steel bar electric induction excitation frequency control apparatus and method

A technology of impedance measurement and excitation frequency, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of affecting the rolling process, uneven temperature field of steel bars, unstable performance of electrical components, etc. The effect of improving the quality of the system, improving the uniformity of the temperature field, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

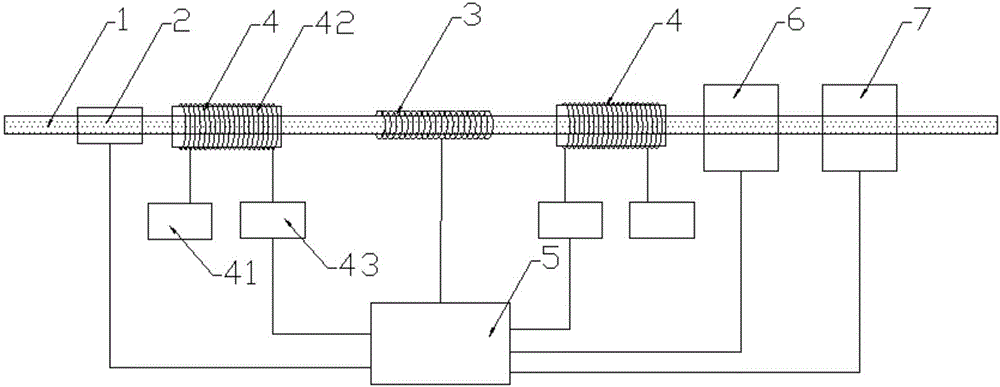

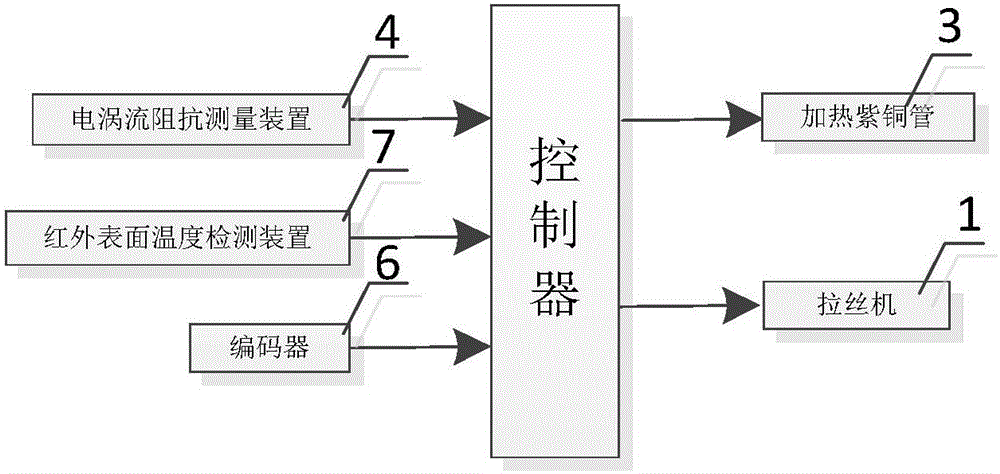

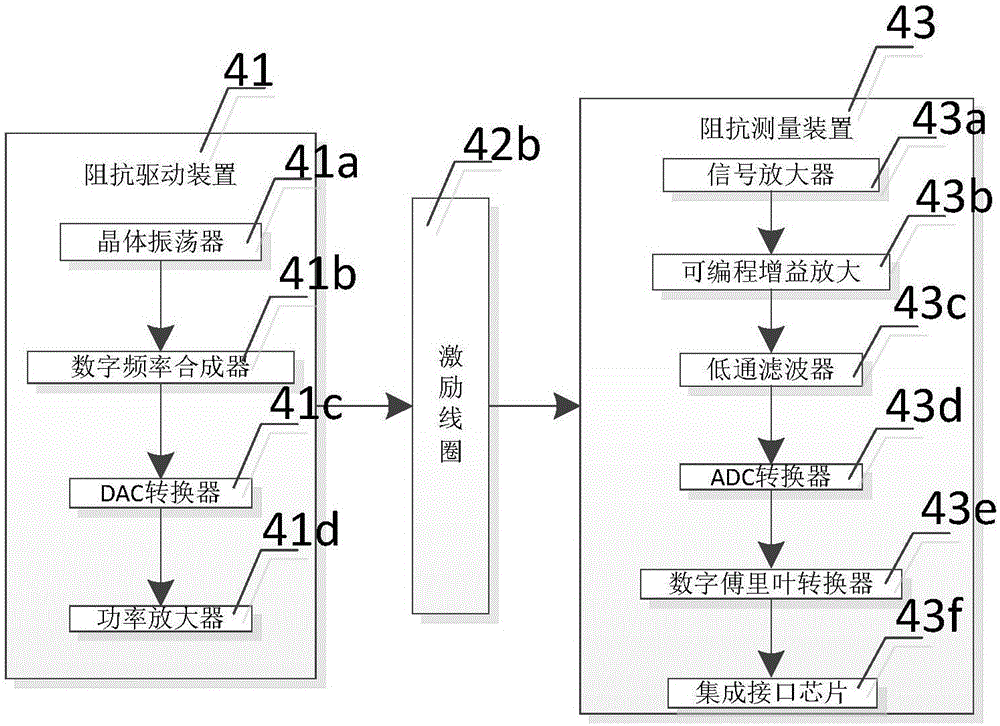

[0039] From figure 1 and figure 2 It can be seen that a PC steel bar electric induction excitation frequency control device based on impedance measurement includes a wire drawing machine 2 arranged on a steel bar conveyor belt 1, a heating copper tube 3 is also arranged on the steel bar conveyor belt 1, and a heating copper tube 3 is installed on the steel bar conveyor belt 1. The upstream and downstream of 3 are respectively provided with an eddy current impedance measuring device 4 with the same structure; the impedance output terminals of the two eddy current impedance measuring devices 4 are respectively connected with the two impedance input terminals of the controller 5, and the two eddy current impedance measuring devices The device 4 transmits the impedance values of the steel bars before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com