Preparation method of titanium-doped iron oxide photo-anode with high photoelectric water decomposition performance

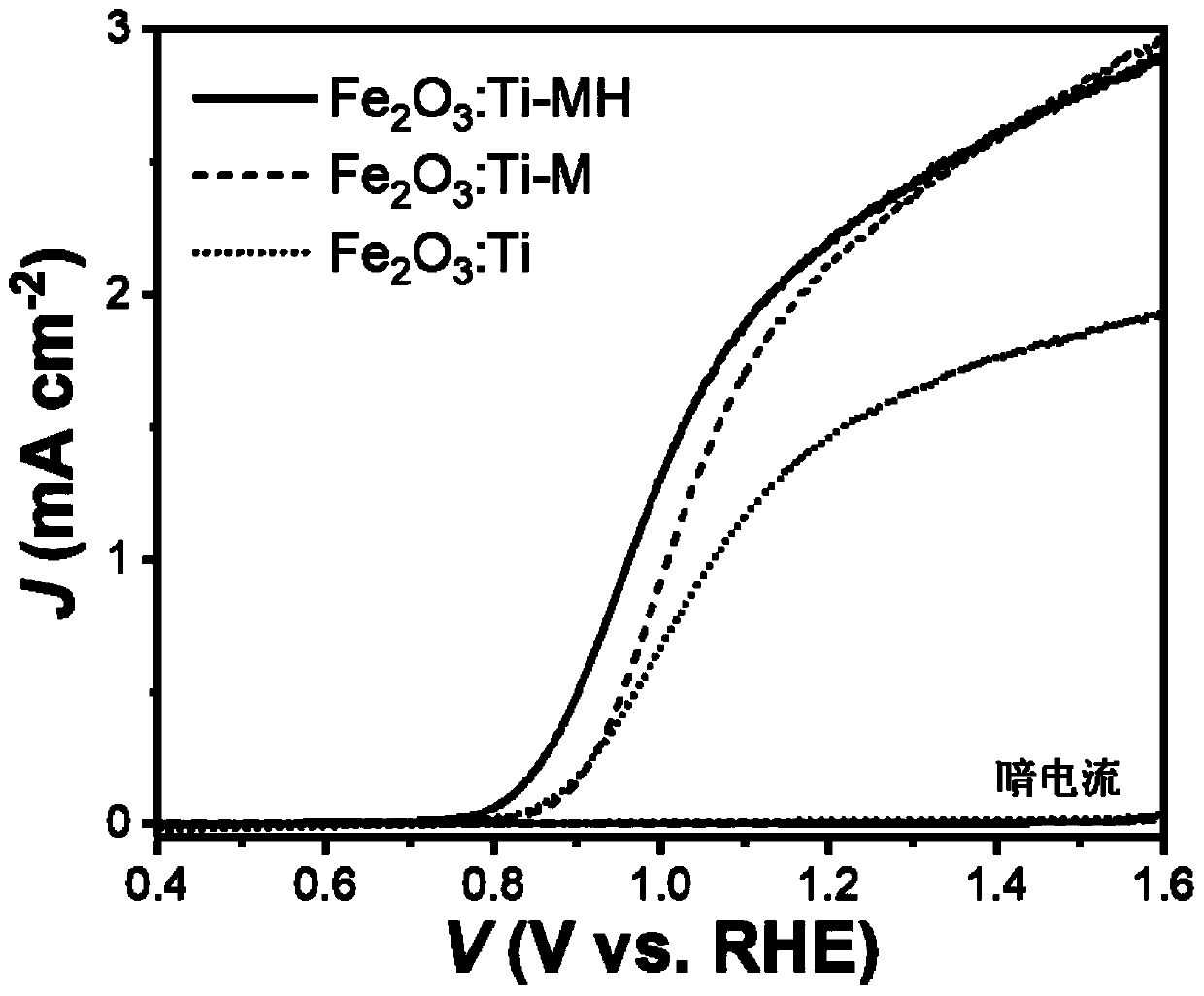

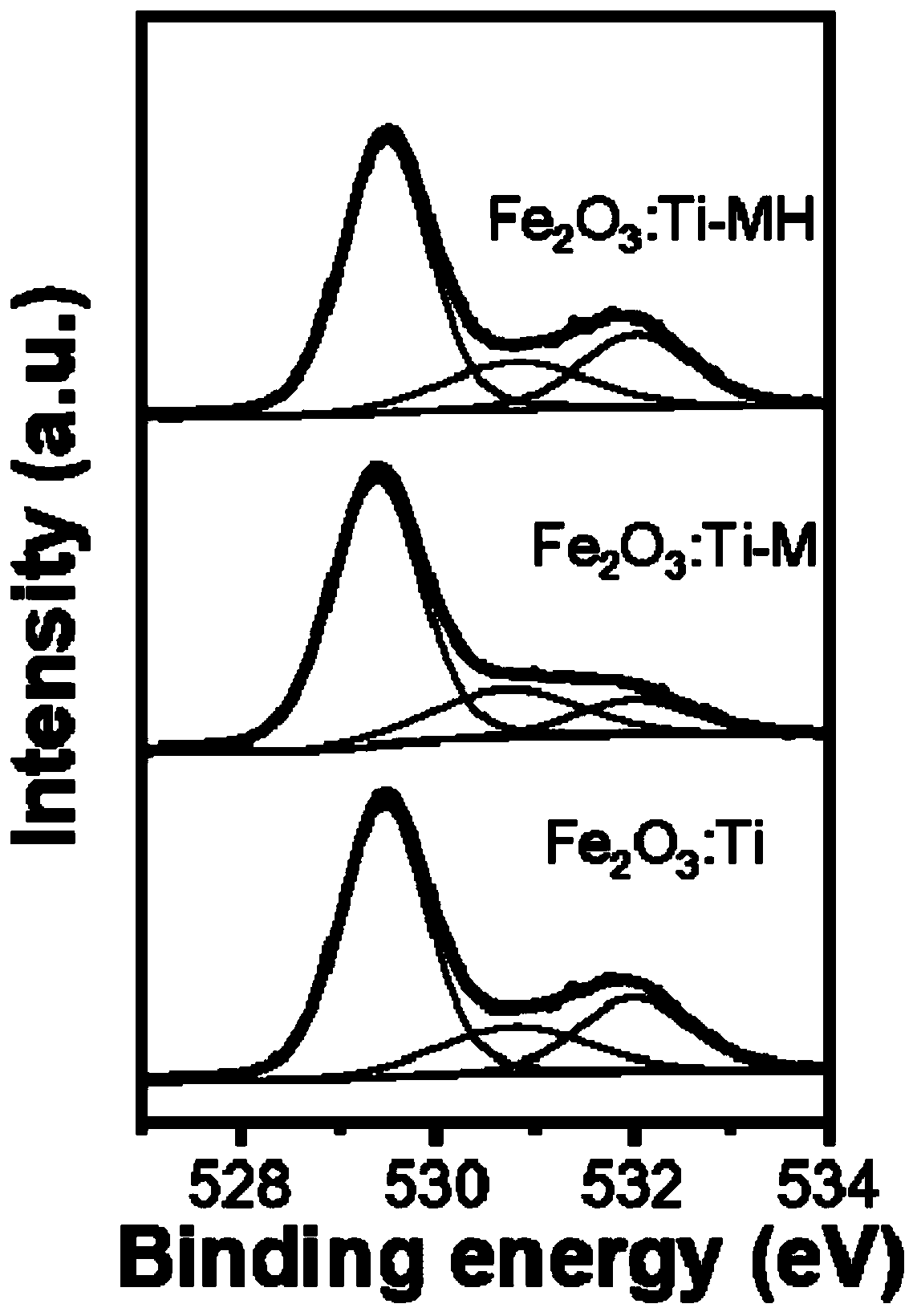

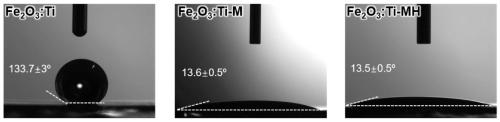

A technology of decomposition performance and iron oxide light, applied in chemical instruments and methods, electrodes, electrolysis process, etc., can solve the problems of high turn-on voltage and low photocurrent density of titanium-doped iron oxide photoelectrode, so as to reduce turn-on voltage and improve Photoelectric water splitting performance and high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a titanium-doped iron oxide photoanode with high photoelectric water splitting performance in this embodiment comprises the following steps:

[0030] 1) 0.61g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Dissolve in 100mL water, stir to dissolve, then add 0.34g sodium acetate (CH 3 COONa), after continuing to stir and dissolve, adjust the pH to 1.5 with 37% concentrated hydrochloric acid, after stirring for 10min, pour it into a 50mL hydrothermal reaction kettle, take 1×2cm 2 A clean FTO glass of the size is vertically immersed in the mixed solution. The reaction kettle was placed in an oven at 95°C for 3 h. After the reaction, the FTO glass was taken out, washed and dried to obtain a β-FeOOH electrode.

[0031] 2) Prepare a butyl titanate ethanol solution with a volume fraction of 1%. The specific preparation method is as follows: add 40 μL of butyl titanate into 4 mL of ethanol, shake to dissolve. Immerse the β-FeOOH electrode in the butyl ...

Embodiment 2

[0036] The difference between embodiment 2 and embodiment 1 is: 0.61g ferric trichloride hexahydrate (FeCl 3 ·6H 2 O) Dissolve in 100mL water, stir to dissolve, then add 0.34g sodium acetate (CH 3 COONa), after continuing to stir and dissolve, adjust the pH to 1.5 with 37% concentrated hydrochloric acid, after stirring for 10min, pour it into a 50mL hydrothermal reaction kettle, take 1×2cm 2A clean FTO glass of the size is vertically immersed in the mixed solution. The reaction kettle was placed in an oven at 95°C for 6 h. After the reaction, the FTO glass was taken out, washed and dried to obtain a β-FeOOH electrode. Prepare a butyl titanate ethanol solution with a volume fraction of 1%, put the obtained β-FeOOH:Ti electrode into a muffle furnace for roasting, and roast it at a heating rate of 10 °C / min to 750 °C for 15 min to obtain Fe 2 o 3 : Ti electrode. the Fe 2 o 3 : The Ti electrode was immersed in a 50mL hydrothermal kettle containing 10mL of methanol, placed ...

Embodiment 3

[0038] 0.61g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Dissolve in 100mL water, stir to dissolve, then add 0.21g sodium nitrate (NaNO 3 ), continue stirring and dissolving, adjust the pH to 1.5 with 37% concentrated hydrochloric acid, stir for 10 minutes, pour into a 50mL hydrothermal reaction kettle, take 1×2cm 2 A clean FTO glass of the size is vertically immersed in the mixed solution. The reaction kettle was placed in an oven at 95°C for 3 h. After the reaction, the FTO glass was taken out, washed and dried to obtain a β-FeOOH electrode. Prepare a butyl titanate ethanol solution with a volume fraction of 1%, immerse the β-FeOOH electrode in the butyl titanate solution, take it out after 5s, place it on a flat surface, and let it dry naturally. Put the obtained β-FeOOH:Ti electrode into a muffle furnace and bake it at a heating rate of 10°C / min to 750°C for 15 minutes to obtain Fe 2 o 3 : Ti electrode. the Fe 2 o 3 : The Ti electrode was immersed in a 50mL hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com