A low contraction, low-modular, heat-resistant UV-thermal dual-curing adhesive and preparation method

A low-modulus, low-shrinkage technology, used in adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problems of poor storage stability, poor process regulation, poor mutual solubility, etc. Good flexibility, low modulus, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

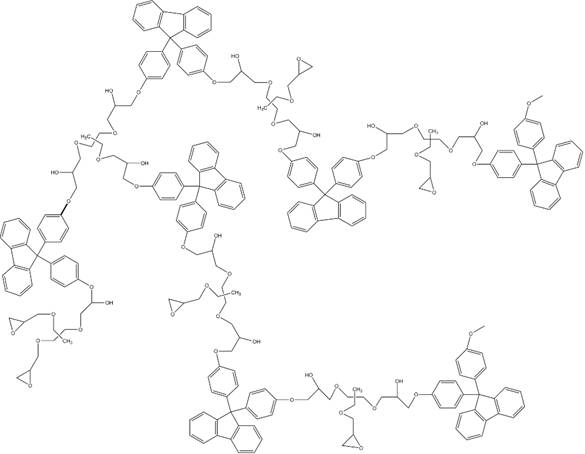

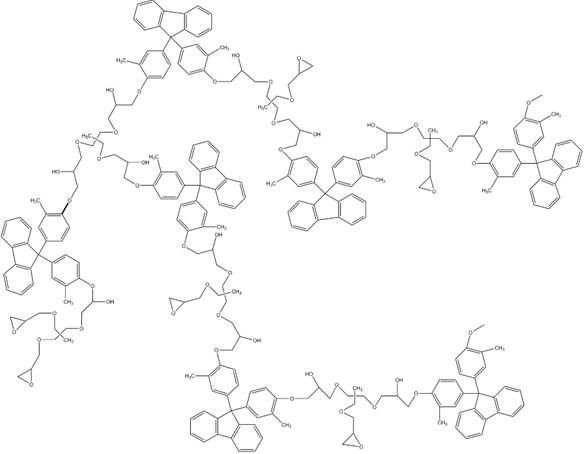

Image

Examples

Embodiment 1

[0058] 15 parts of self-made hyperbranched epoxy resin containing fluorene skeleton, 20 parts of bisphenol A epoxy resin, 10 parts of DAP, 5 parts of tetrahydrofuran methacrylate, 4 parts of 1-hydroxycyclohexyl benzophenone, 1 part of Parts of 3-(2,3-glycidoxy)propyltrimethoxysilane, 1.5 parts of benzoic acid were added to the above-mentioned premix, under vacuum and dark state, revolution 30r / min, autorotation 800r / Under the condition of 1 min, stir for 30 min; add 0.2 part of carbon black, 20 parts of tetrakis (3-mercaptopropionic acid) pentaerythritol ester, control the temperature not higher than 35 ℃, in the state of vacuum and dark, revolution 15r / min, rotate 600r / min Under the conditions, stir for 30min; add 20 parts of silicon micropowder, control the temperature not to be higher than 25℃, under the condition of vacuum and light-proof, under the condition of revolution 10r / min, stir for 30min; add 3.5 parts of PN-23.5 parts, control the temperature not to be higher tha...

Embodiment 2

[0062] 20 parts of self-made hyperbranched epoxy resin containing fluorene skeleton, 15 parts of bisphenol F epoxy resin, 10 parts of DAIP, 8 parts of 3,3,5 trimethylcyclohexane acrylate, 5 parts of 1- Hydroxycyclohexyl benzophenone, 1 part of 3-(2,3-glycidoxy)propyltrimethoxysilane, 1.8 parts of benzoic acid were added to the above premix, and revolutionized in a vacuum and dark state. 30 r / min, under the condition of autorotation 800 r / min, stir for 30 min; add 0.2 part of carbon black, 20 parts of trimethylolpropane tris(3-mercaptopropionate), control the temperature not higher than 35 ℃, avoid in vacuum Under the condition of light state, under the condition of revolution 15r / min, under the condition of autorotation 600r / min, stir for 30min; add 15 parts of talc powder, control the temperature not higher than 25 ℃, under the condition of vacuum and dark, under the condition of revolution 10r / min, stir for 30min; Add 3.5 parts of EH-5031S, control the temperature not to be ...

Embodiment 3

[0066] 20 parts of self-made hyperbranched epoxy resin containing fluorene skeleton, 18 parts of novolac epoxy resin, 5 parts of triallyl isocyanurate, 10 parts of isobornyl methacrylate, 5 parts of 2 -Hydroxy-2-methyl-1-phenylacetone, 1 part of bis(2,4,6-trimethylbenzoyl)phenylphosphonium oxide, 1.5 parts of 3-aminopropyltriethoxysilane , 1 part of barbituric acid is added to the above premix, under the condition of vacuum and dark, revolution 40 r / min, under the condition of autorotation 800 r / min, stir for 30min; add 0.2 part of carbon black, trimethylol 25 parts of propane trimercaptoacetate, the control temperature is not higher than 35 ℃, under the condition of vacuum and dark, revolution 15r / min, under the condition of autorotation 600r / min, stir for 30min; add 15 parts of silicon powder, control the temperature not higher than 25℃, under the condition of vacuum and light-proof, under the condition of revolution 10r / min, stir for 30min; add 4.5 parts of EH-4070S, contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com