Method for synthesizing ultrahigh-viscosity lithium carboxymethyl cellulose of ultralow solvent system

A technology of carboxymethyl cellulose and synthesis method, which is applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of low conversion efficiency of carboxymethyl cellulose lithium, many residual ions, and large amount of solvent, etc., and achieve product conversion Efficiency improvement, low residual sodium salt content, and small amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

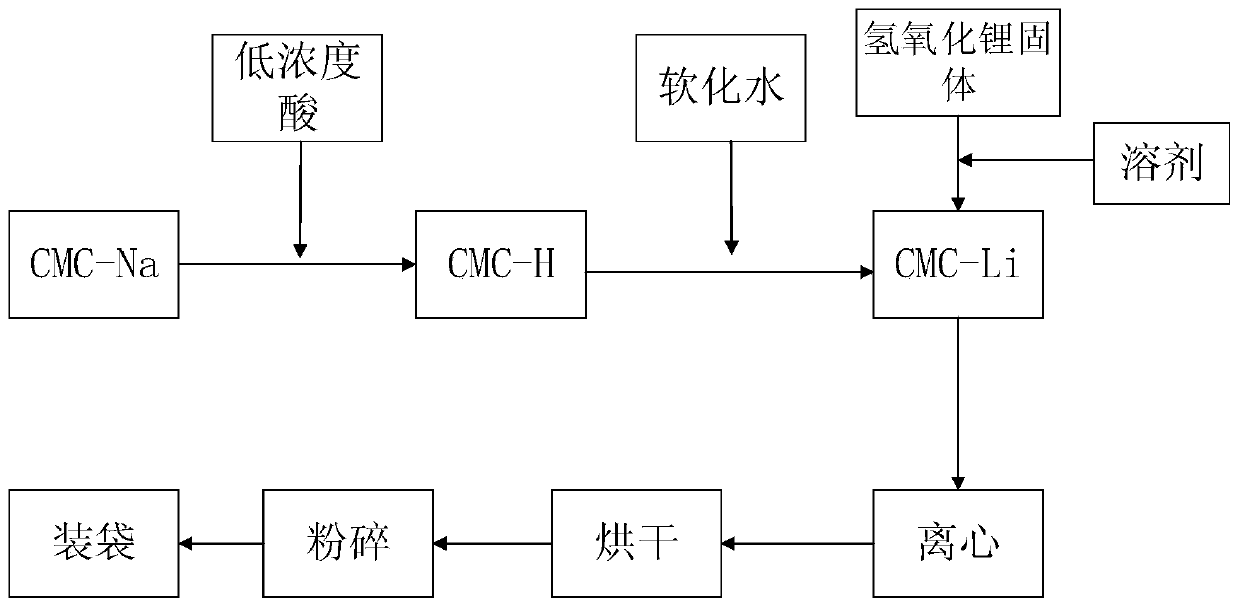

Embodiment 1

[0028] In a 5-liter vertical enamel reactor, take 1000g of CMC-Na and 4050g of 10% sulfuric acid solution into the glass-lined reactor. Stir continuously at 20°C. After 120min, stop the reaction and centrifuge to remove the mother liquor. Later, the solid was retained to obtain CMC-H. Spray and wash the materials in the centrifuge with demineralized water at 40°C for 20 minutes, and discharge the materials. Add all the CMC-H obtained by centrifugation to 5 times the mass of an 80% alcohol system, stir continuously, add 0.36kg of solid lithium hydroxide, react at 35°C for 120min, and then centrifuge. After the mother liquor is removed by centrifugation, the material in the centrifuge is sprayed and washed with 70% ethanol for 20 minutes, and the material is discharged to obtain CMC-Li, which can be dried, crushed and sieved.

Embodiment 2

[0030] In a 5-liter vertical reactor, take 1 kg of CMC-Na and 2 kg of sulfuric acid solution with a concentration of 30% and add it to the glass-lined reactor. Stir continuously at 35 ° C. After 100 minutes, stop the reaction and perform centrifugation. After the mother liquor is removed by centrifugation , The solid was retained to give CMC-H. Spray and wash the materials in the centrifuge with demineralized water at 50°C for 18 minutes, and discharge the materials. Add all the CMC-H obtained by centrifugation to 8 times the mass of an 85% alcohol system, stir continuously, add 0.36kg of solid lithium hydroxide, react at 40°C for 120min, and then centrifuge. After the mother liquor is removed by centrifugation, the material in the centrifuge is sprayed and washed with 75% ethanol for 20 minutes, and the material is discharged to obtain CMC-Li, which can be dried, crushed and sieved.

Embodiment 3

[0032] In a 5-liter vertical reactor, take 200g of CMC-Na and 972g of 25% sulfuric acid solution into the glass-lined reactor. Stir continuously at 40°C. After 150min, stop the reaction and centrifuge. After the mother liquor is removed by centrifugation , The solid was retained to give CMC-H. Spray and wash the materials in the centrifuge with demineralized water at 35°C for 16 minutes, and discharge the materials. Add all the CMC-H obtained by centrifugation to 10 times the mass of an 85% alcohol system, stir continuously, add 35g of solid lithium hydroxide, react at 40°C for 120min, and then centrifuge. After the mother liquor is removed by centrifugation, the materials in the centrifuge are sprayed and washed with 80% ethanol for 15 minutes, and the materials are discharged to obtain CMC-Li, which can be dried, pulverized and sieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com