A kind of strong acid type high temperature resistant cationic resin catalyst and preparation method thereof

A cationic resin, high temperature resistant technology, used in catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of difficult to meet technical needs, limited application scope, inability to balance catalytic activity and temperature resistance, etc. problem, to achieve the effect of having both catalytic activity and high temperature resistance, improving electron distribution, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

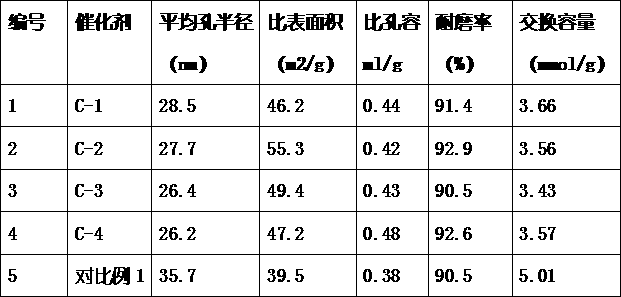

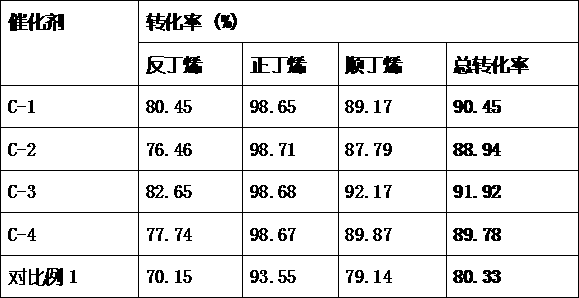

Examples

Embodiment 1

[0018] Embodiment 1——preparation of catalyst C-1

[0019] ①. Suspension polymerization: add the water phase to the stainless steel stirred tank with a condensing reflux device, add the oil phase when the temperature rises to 60°C, continue to heat up to 80°C during stirring, and react for 8 hours, and the stirring speed is 80 rpm;

[0020] Wherein, by weight, the water phase is a mixture of 20 parts of disodium lauryl sulfosuccinate monoester, 20 parts of potassium monododecyl phosphate and 4000 parts of water; the oil phase is a mixture of 500 parts of styrene parts, 1000 parts of divinylbenzene and 30 parts of benzoyl peroxide;

[0021] ②. Stable structure

[0022] Soak the polymerized white balls obtained in step ① in a solvent, stir and soak for 10 hours at a stirring speed of 80 rpm, then raise the temperature to 80°C and keep it constant for 5 hours, wherein the solvents are n-hexane, n-octane and one of cyclohexane;

[0023] ③.Halogenation

[0024] Soak the resin wh...

Embodiment 2

[0030] Embodiment 2——preparation of catalyst C-2

[0031] ①. Suspension polymerization: Add the water phase to the stainless steel stirred tank with condensing reflux device, add the oil phase when the temperature rises to 70°C, continue to heat up to 90°C during stirring, and react for 10 hours, and the stirring speed is 100 rpm;

[0032] Wherein, by weight, the water phase is a mixture of 50 parts of disodium lauryl sulfosuccinate monoester, 30 parts of potassium monododecyl phosphate and 4200 parts of water; the oil phase is a mixture of 800 parts of styrene 700 parts of divinylbenzene and 30 parts of benzoyl peroxide;

[0033] ②. Stable structure

[0034] Soak the polymerized white balls obtained in step ① in a solvent, stir and soak for 11 hours, the stirring speed is 110 rpm, then raise the temperature to 90°C, and keep it constant for 6 hours, wherein the solvent is n-hexane, n-octane and one of cyclohexane;

[0035] ③.Halogenation

[0036] Immerse the resin white b...

Embodiment 3

[0042] Embodiment 3——preparation of catalyst C-3

[0043] ①. Suspension polymerization: Add the water phase to the stainless steel stirred tank with a condensing reflux device, add the oil phase when the temperature rises to 65°C, continue to heat up to 80°C during stirring, and react for 9 hours, and the stirring speed is 120 rpm;

[0044] Wherein, by weight, the water phase is a mixture of 50 parts of disodium lauryl sulfosuccinate monoester, 40 parts of potassium monododecyl phosphate and 4500 parts of water; the oil phase is 500 parts of styrene parts, 1000 parts of divinylbenzene and 30 parts of benzoyl peroxide;

[0045] ②. Stable structure

[0046] Soak the polymerized white balls obtained in step ① in a solvent, stir and soak for 10 hours at a stirring speed of 100 rpm, then raise the temperature to 90°C and keep it constant for 6 hours, wherein the solvents are n-hexane, n-octane and one of cyclohexane;

[0047] ③.Halogenation

[0048] Immerse the resin white ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com