Surface gold-modified high-loading-capacity carbon-loaded platinum-cobalt catalyst as well as preparation method and application thereof

A technology of cobalt catalyst and carbon-supported platinum, which is applied in nanotechnology for materials and surface science, electrochemical generators, fuel cells, etc., can solve the problems of stable MA attenuation and cumbersome process, and achieve improved stability, The effect of simple process and close contact with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

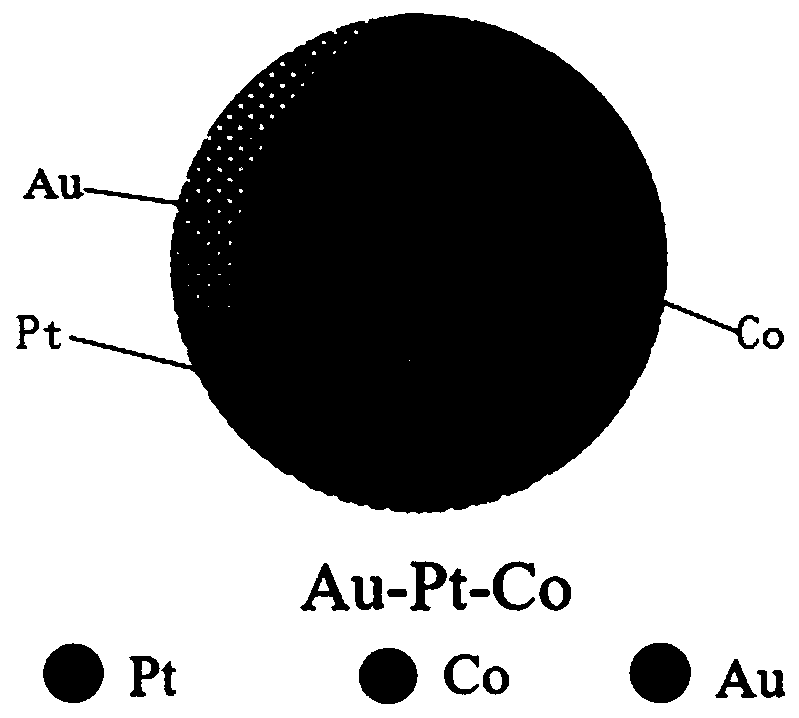

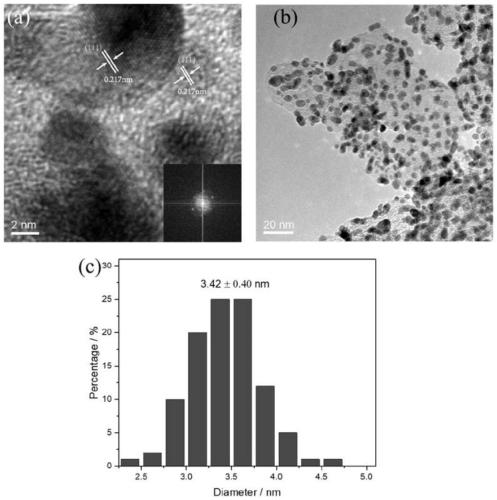

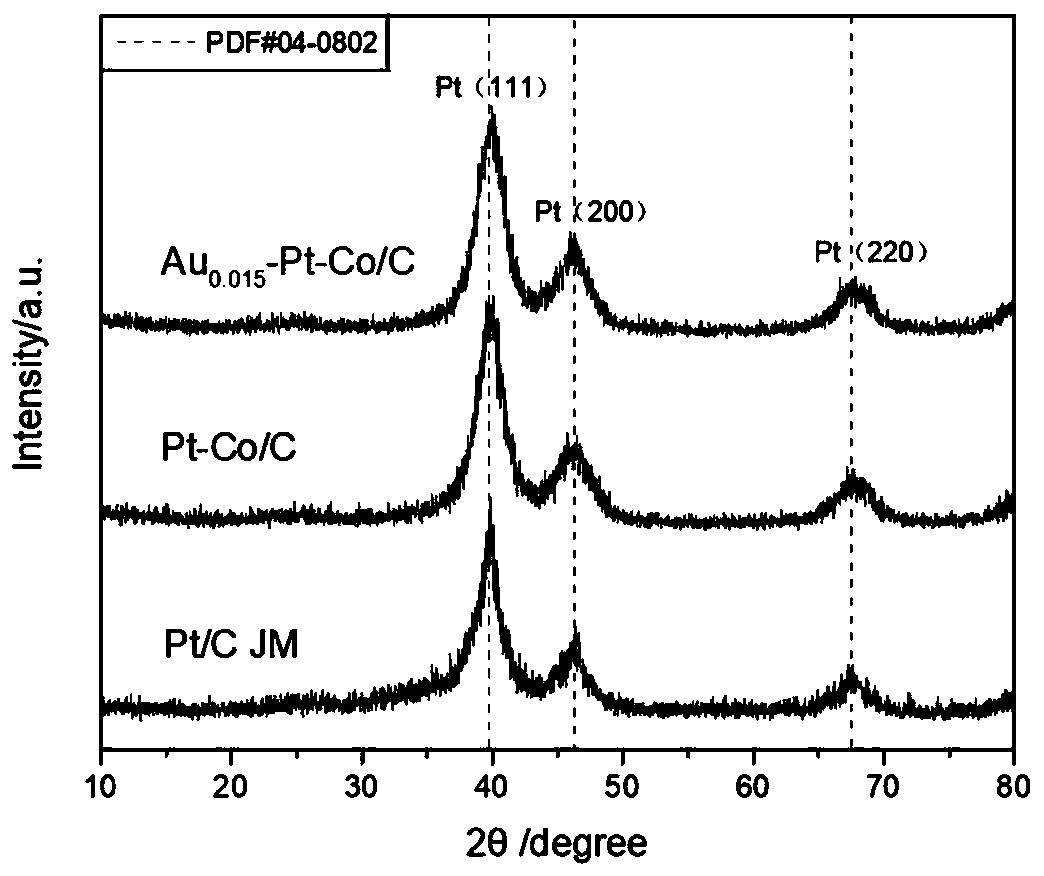

[0048] The surface gold-modified high-capacity carbon-supported platinum-cobalt catalyst of this embodiment includes a carbon support and gold-platinum-cobalt particles on it. The particle size of the particles is 2 to 5 nm. The particles have a Pt-rich surface, Co is distributed inside the particles, and Au Distributed on the particle surface, and the Pt loading in the catalyst is 50.2wt.%.

[0049] The preparation method of the catalyst in this example is as follows: take a three-necked round-bottomed flask with a capacity of 500 mL, wash and dry it for later use. Measure 175mL of ethylene glycol with a graduated cylinder and pour it into the flask, then add 14.48mL of chloroplatinic acid solution (38.6mM) prepared in advance. Weigh 123mg of cobalt chloride hexahydrate with an electronic balance, dissolve it in 10mL of ethylene glycol, and transfer the cobalt chloride solution to the flask after ultrasonic dissolution, then weigh 80mg of conductive carbon black (EC300) with ...

Embodiment 2

[0071] The surface gold-modified high-capacity carbon-supported platinum-cobalt catalyst of this embodiment includes a carbon support and gold-platinum-cobalt particles on it. The particle size of the particles is 2 to 5 nm. The particles have a Pt-rich surface, Co is distributed inside the particles, and Au Distributed on the particle surface, and the Pt loading in the catalyst is 60wt.%.

[0072] The preparation method of the catalyst in this example is as follows: take a three-necked round-bottomed flask with a capacity of 500 mL, wash and dry it for later use. Measure 175mL of ethylene glycol with a graduated cylinder and pour it into the flask, then add 15mL of chloroplatinic acid solution (38.6mM) prepared in advance. Weigh 128mg of cobalt chloride hexahydrate with an electronic balance, dissolve it in 10mL of ethylene glycol, transfer the cobalt chloride solution to the flask after ultrasonic dissolution, then weigh 60mg of conductive carbon black (EC300) with an electr...

Embodiment 3

[0075] The surface gold-modified high-capacity carbon-supported platinum-cobalt catalyst of this embodiment includes a carbon support and gold-platinum-cobalt particles on it. The particle size of the particles is 2 to 5 nm. The particles have a Pt-rich surface, Co is distributed inside the particles, and Au Distributed on the particle surface, and the Pt loading in the catalyst is 55.6wt.%.

[0076] The preparation method of the catalyst in this example is as follows: take a three-necked round-bottomed flask with a capacity of 500 mL, wash and dry it for later use. Use a graduated cylinder to measure 175mL of ethylene glycol and pour it into the flask, then add 12.4mL of a pre-prepared chloroplatinic acid solution (38.6mM). Weigh 105mg of cobalt chloride hexahydrate with an electronic balance, dissolve it in 10mL of ethylene glycol, and transfer the cobalt chloride solution to the flask after ultrasonic dissolution, then weigh 55mg of conductive carbon black (EC300) with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com