Method for improving strength of rare earth-iron-boron permanent magnet

A permanent magnet and rare earth technology, which is applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of NdFeB instability in the main phase, reduce the magnetic polarization of magnets, and reduce the magnetic properties of materials to achieve continuity Reinforcement, high qualified rate of finished products, enhanced effect of grain boundary strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

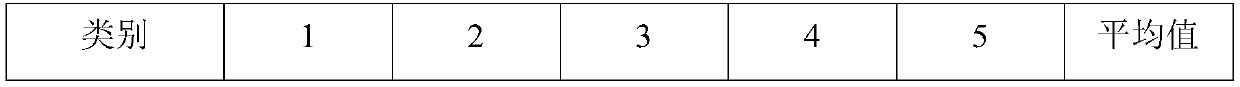

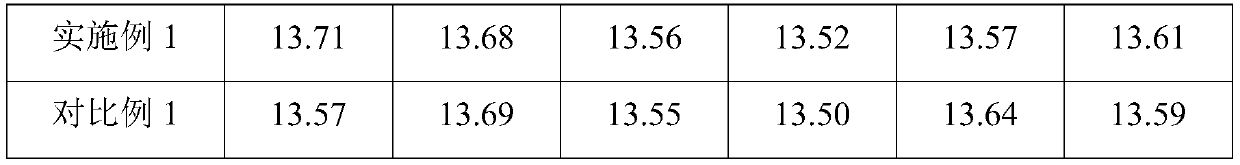

Embodiment 1

[0046] Select ferroniobium alloy with niobium Nb content of 65%, and the formula composition is (PrNd) 29.5 Dy 1.5 Fe 66.32 B 0.98 W 0.15 co 1.0 Cu 0.15 al 0.4 Praseodymium neodymium iron boron, vacuum smelted at 0.05Pa and 1460°C respectively, then rapidly cooled by rolling copper rolls to prepare niobium-iron Nb-Fe alloy with an average thickness of 0.20mm (the average thickness of 100 samples) Flakes and praseodymium neodymium iron boron alloy flakes;

[0047] The praseodymium-neodymium-iron-boron alloy flakes are crushed by hydrogen crushing process: first, put the praseodymium-neodymium-iron-boron alloy flakes into the hydrogen crushing furnace, vacuumize (vacuum degree below 1 Pa), and then pass in hydrogen gas for hydrogen absorption and crushing, and crush the flakes into coarse powder; then dehydrogenation treatment at 560°C for more than 10 hours, when the vacuum degree reaches below 10Pa, the dehydrogenation is completed, and the water is cooled to below 40°C...

Embodiment 2

[0063] Select ferroniobium alloy with niobium Nb content of 65%, and the formula composition is (PrNd) 29.5 Tb 1.0 Fe 67 B 1.0 V 0.15 co 0.8 Cu 0.15 Ga 0.2 al 0.2 Praseodymium neodymium iron boron, vacuum smelted at 0.05Pa and 1440°C respectively, and then rapidly cooled by rolling copper rolls to prepare ferroniobium Nb-Fe alloy with an average thickness of 0.30mm (the average thickness of 100 samples) Flakes and praseodymium neodymium iron boron alloy flakes;

[0064] The praseodymium-neodymium-iron-boron alloy flakes are crushed by hydrogen crushing process: first, put the praseodymium-neodymium-iron-boron alloy flakes into the hydrogen crushing furnace, vacuumize (vacuum degree below 1 Pa), and then pass in hydrogen gas for hydrogen absorption and crushing, and crush the flakes into coarse powder; then dehydrogenation treatment at a high temperature of 560°C for more than 10 hours, when the vacuum degree reaches below 6Pa, the dehydrogenation is completed, and the ...

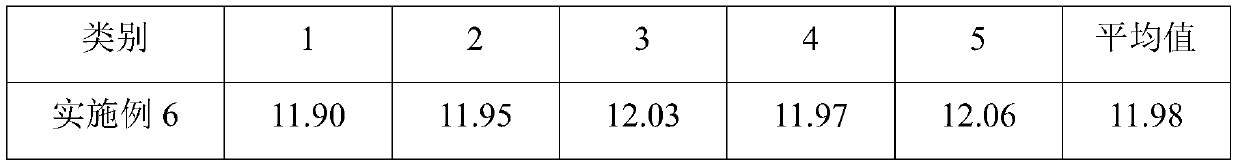

Embodiment 3

[0079] Select ferroniobium alloy with niobium Nb content of 65%, and the formula composition is (PrNd) 31 Dy 1 Fe 65.94 B 1.01 co 0.5 Cu 0.15 Al 0.4 Praseodymium neodymium iron boron, vacuum smelted at 0.05Pa and 1430°C respectively, then rapidly cooled by rolling copper rolls to prepare ferroniobium Nb-Fe alloy with an average thickness of 0.40mm (the average thickness of 100 samples) Flakes and praseodymium neodymium iron boron alloy flakes;

[0080] The praseodymium-neodymium-iron-boron alloy flakes are crushed by hydrogen crushing process: first, put the praseodymium-neodymium-iron-boron alloy flakes into the hydrogen crushing furnace, vacuumize (vacuum degree below 1 Pa), and then pass in hydrogen gas for hydrogen absorption and crushing, and crush the flakes into coarse powder; then dehydrogenation treatment at a high temperature of 560°C for more than 12 hours, when the vacuum degree reaches below 8Pa, the dehydrogenation is completed, and the water is cooled to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com