Composite functional coating and film, and preparation method and application thereof

A composite, coating technology, applied in coatings, anti-corrosion coatings, luminescent coatings, etc., can solve problems such as micro- and nano-scale gaps, and achieve the effect of improving performance, enhancing ion transmission and embedding effect, and enhancing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

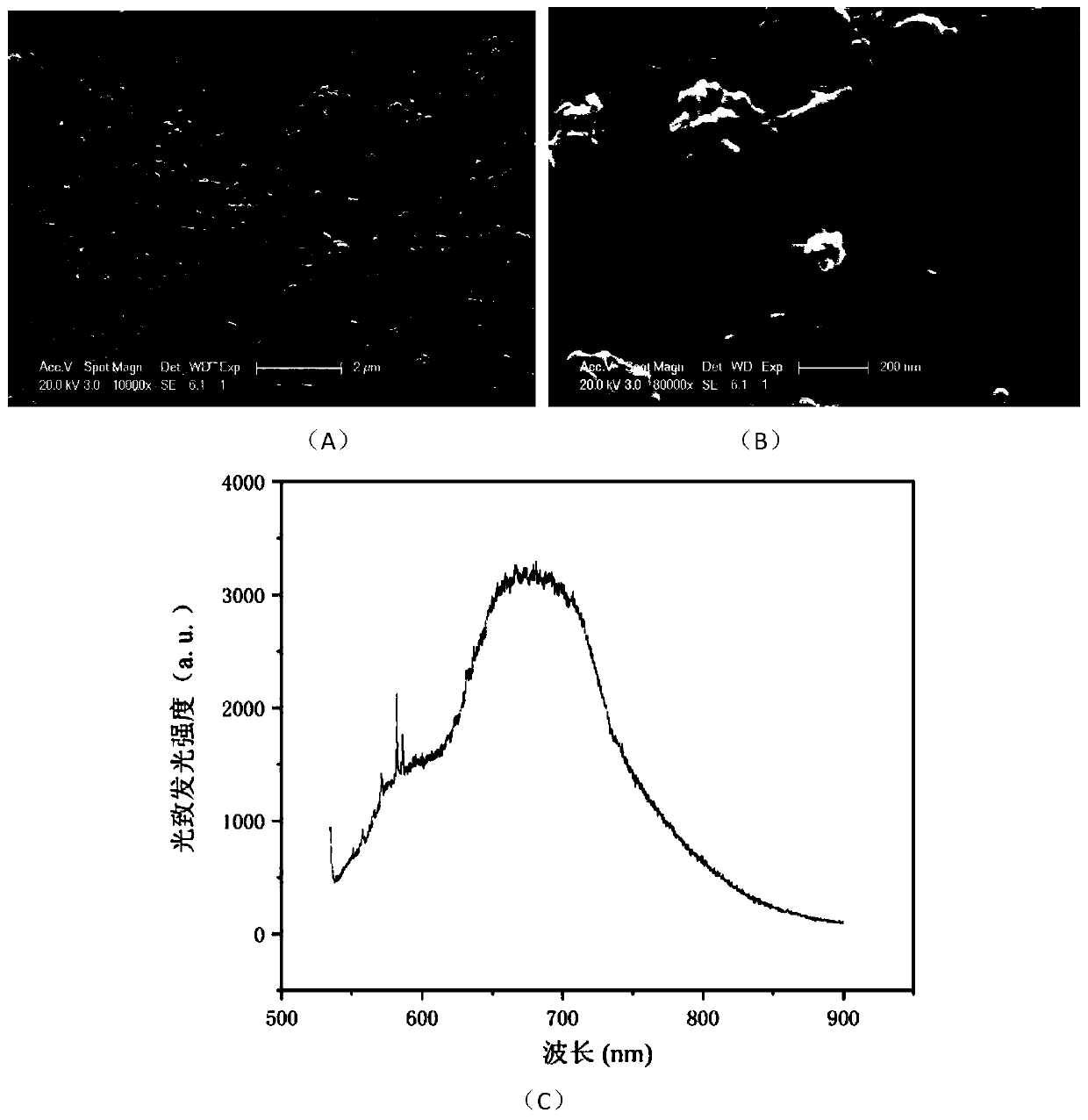

Embodiment 1

[0046] Prepare 0.1 mol / L zinc sulfate (ZnSO 4 ) aqueous solution, 0.5 mol / liter sodium thiocyanate (NaSCN) aqueous solution, for later use.

[0047] For the preparation method of the cuprous oxide nanowire film, refer to the previous invention patents. [(1) Xu Wei, Xiao Xingxing, Xia Peng, A cuprous oxide nanowire porous film and its preparation method and application, invention patent application number: 2014100140030].

[0048] Copper films were deposited on flexible plastic substrates by vacuum thermal evaporation. The copper film is immersed in the thiocyanate aqueous solution to react, and after completion, it is taken out, washed, and then reacted with the sodium hydroxide aqueous solution to prepare the cuprous oxide nanowire film grown on the flexible plastic substrate, which is ready for use.

[0049] Mix 10 ml of 0.5 mol / L sodium thiocyanate solution with 20 ml of 0.1 mol / L zinc sulfate aqueous solution to form a "zinc ion-thiocyanate" aqueous solution system, and ...

Embodiment 2

[0055] The preparation method is similar to Example 1, but the precipitating agent uses sodium tungstate aqueous solution.

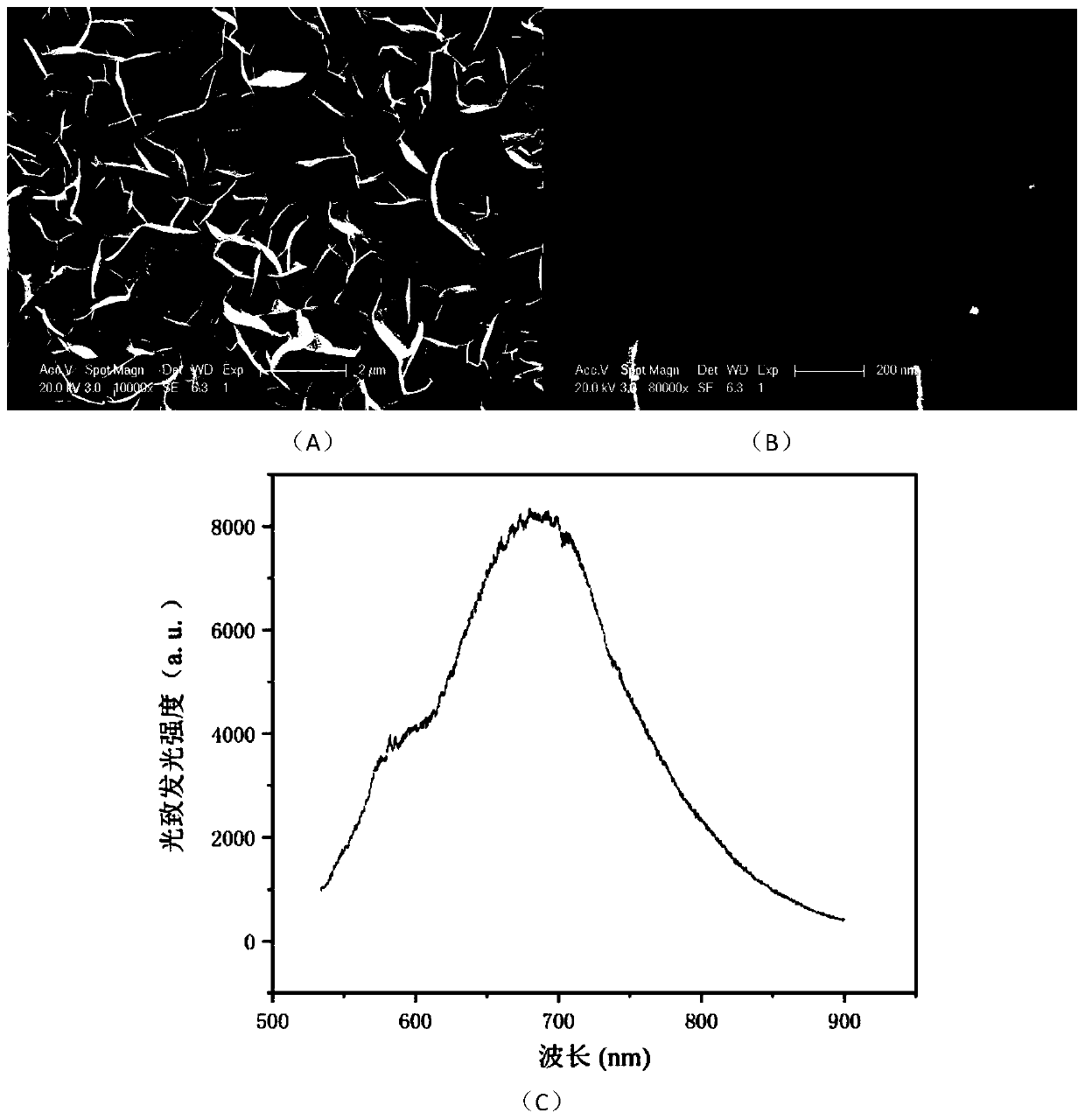

[0056] The composite product obtained by this method should be a composite of zinc tungstate nanomaterials and cuprous oxide nanowires, and there may also be other components or different aggregation forms. The SEM image shows that the aggregated morphology of the film is very special, which is connected into a honeycomb-like structure by ultra-thin nanosheets, such as figure 2 (A) and 2(B).

[0057] Further tests have demonstrated that this simple complex-precipitate film has even stronger photoluminescent properties. Under the excitation of green light (532 nm), it can emit higher brightness red light, such as figure 2 (C) shown.

[0058] Many kinds of composite functional coatings and functional films can be prepared by changing the experimental formula, including the amount of thiocyanate, using similar methods. Such films can be used as lumine...

Embodiment 3

[0061] Referring to the method in Example 1, replace the plastic substrate with other substrates, and then use a similar method to prepare zinc oxide and cuprous oxide nanowire composite films to obtain photoelectric functional films on different substrates.

[0062] This method also allows the preparation of marine antifouling coatings:

[0063] Copper film is deposited on the surface of steel and alloy components by chemical coating method (or electrochemical coating method), and then reacted with thiocyanate aqueous solution and sodium hydroxide aqueous solution in turn to prepare cuprous oxide nanowire film. Then adopt the method similar to Example 1, replace the "zinc ion-thiocyanate" aqueous solution with various "metal ion-thiocyanate" aqueous solutions, prepare cuprous oxide nanowire film and various "metal ion-thiocyanate" respectively Acid radical” aqueous solution composite solid-liquid interface system, and then treated with alkali solution, can prepare composite c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com