A kind of solder paste and preparation method thereof

A solder paste and flux paste technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of affecting electrical conductivity and strength, high arc welding cost, low rivet connection efficiency, etc., to improve production efficiency, Improve printing resistance and good soldering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

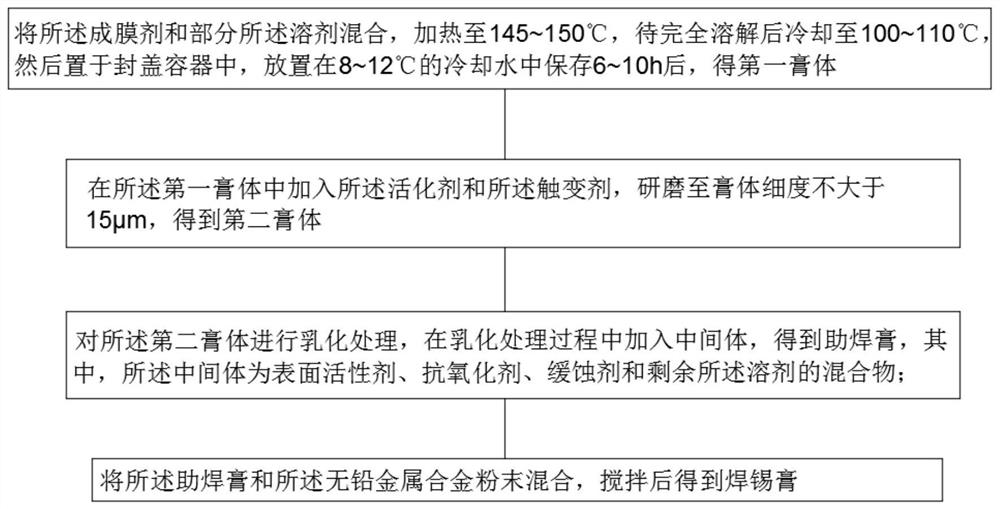

[0032] The embodiment of the present invention also provides the preparation method of the above-mentioned solder paste, comprising the following steps:

[0033] S1, mix the film-forming agent and part of the above-mentioned solvents, heat to 145-150°C, cool to 100-110°C after completely dissolving, then place in a container with a cover, and store in cooling water at 8-12°C for 6 After ~10 hours, the first paste was obtained.

[0034] S2, adding an activator and a thixotropic agent to the first paste, and grinding until the fineness of the paste is not greater than 15 μm, to obtain a second paste. In this step, an activator and a thixotropic agent are firstly added and ground together with the first paste to prevent the paste from forming micelles. In a preferred embodiment, the grinding step is: rough grinding twice and then fine grinding once, repeating the above grinding process until the fineness of the paste is less than 15 μm.

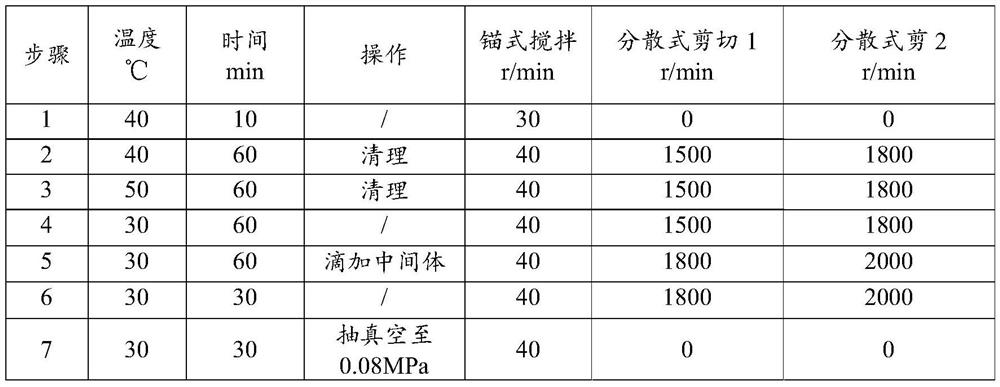

[0035] S3, emulsifying the second paste...

Embodiment 1

[0053] A kind of solder paste provided by this embodiment is prepared according to the following steps:

[0054] 1) The components of the solder paste were obtained in the following parts by weight: 30 parts of hydrogenated rosin resin, 8 parts of polymerized rosin, 5 parts of pentaerythritol rosin ester, 20 parts of dibutyl succinate, 16 parts of ethylene glycol phenyl ether, 4-n- 6 parts of butyl benzoic acid, 6 parts of polyacid, 1.2 parts of 2,3-dibromosuccinic acid, 4 parts of polyamide wax, 0.8 parts of fumed silica, 2 parts of tetrakis (2-hydroxypropyl) ethylenediamine 0.5 part, 0.5 part of antioxidant 1010, 0.5 part of triallyl isocyanurate.

[0055] 2) Add hydrogenated rosin resin, polymerized rosin, and pentaerythritol rosin ester to part of the solvent, heat to 150°C to dissolve, cool naturally to 105°C, and cover in initial cooling water (10±2°C) for eight hours Then grind.

[0056] 3) Add an activator and a thixotropic agent to the above 2) and grind until the p...

Embodiment 2

[0065] A kind of solder paste provided by this embodiment is prepared according to the following steps:

[0066] 1) Obtain the components of the soldering paste according to the following parts by weight: 28 parts of acrylic rosin, 6 parts of polymerized rosin, 7 parts of polyethylene glycol 1500, 18 parts of triethylene glycol propyl ether, and 18 parts of dibutyl maleate , 5 parts of p-hydroxyphenylacetic acid, 8 parts of maleic acid, 1.8 parts of 2,3-dibromobutene diol, 4.5 parts of ethylene bislauric acid amide, 0.6 parts of fumed silica, 2.2 parts of aniline, anti 0.6 part of oxygen agent BHT, 0.3 part of 2-phenylimidazole.

[0067] 2) Add acrylic rosin, polymerized rosin, and polyethylene glycol 1500 to an organic solvent, heat to 150°C to dissolve, cool naturally to 105°C, and cover in initial cooling water (10±2°C), Grind after eight hours.

[0068] 3) Add an activator and a thixotropic agent to the above 2) and grind until the paste fineness is less than 15 μm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com