A kind of washing flux paste, solder paste and preparation method thereof

A technology of flux paste and water washing, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as affecting the fluxing activity of fluxing paste, and achieve good tin melting effect, good fluxing activity, and enhanced solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of a kind of water-washing flux paste

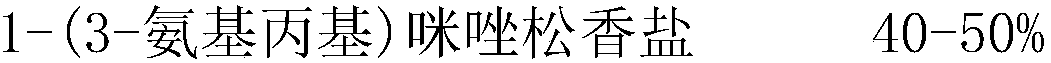

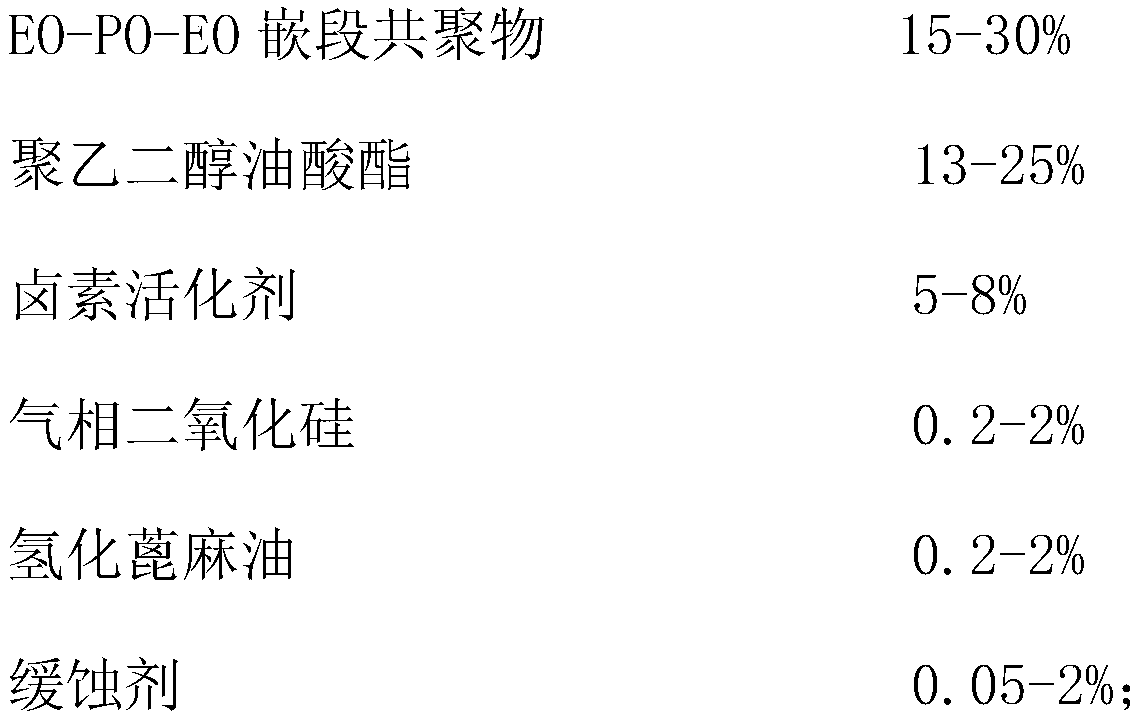

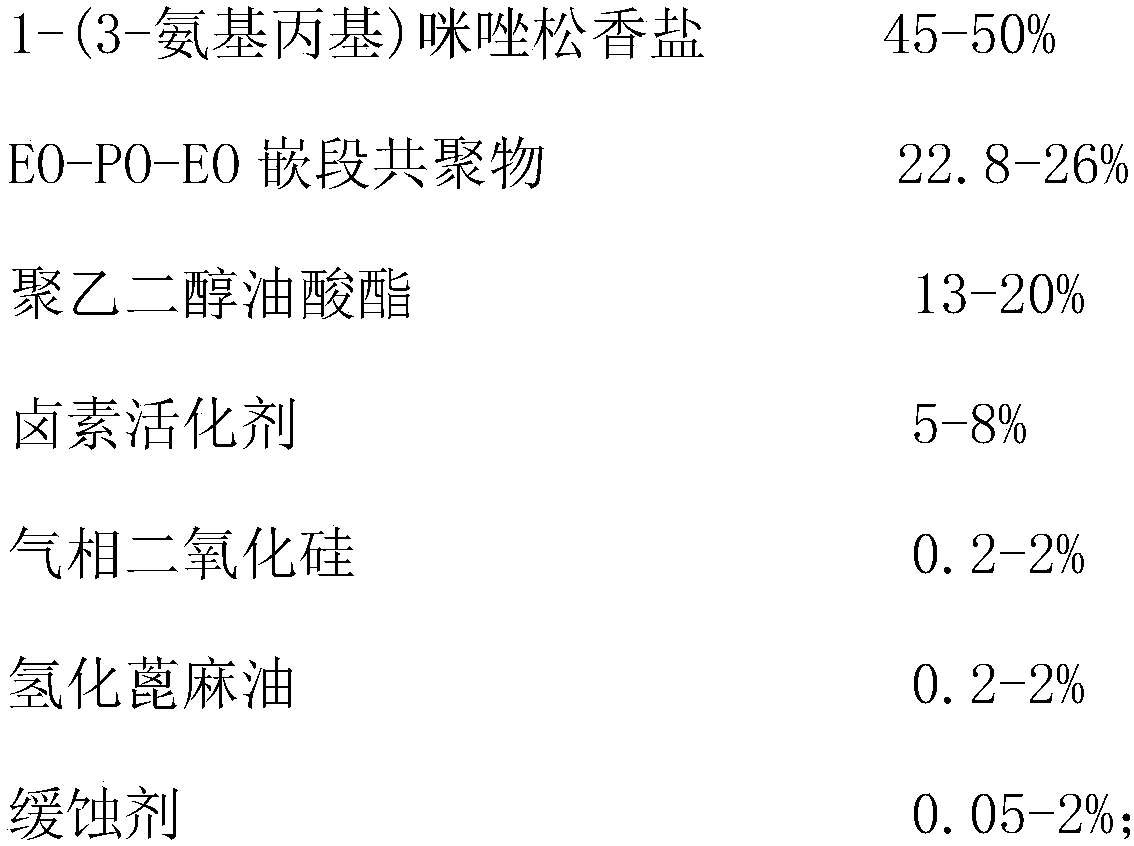

[0045] Table 1 Example 1-5 Washing Flux Paste Formulation (w / w%)

[0046]

[0047]

[0048] Preparation of 1-(3-aminopropyl)imidazole rosin salt: 1-(3-aminopropyl)imidazole and hydrogenated rosin are dissolved in isopropanol at a molar ratio of 1:1, neutralized and then dried.

[0049] Raw material formula: see Table 1.

[0050] Preparation:

[0051] 1-(3-aminopropyl)imidazole rosin salt, Add PE 3100, polyethylene glycol 400 monooleate, 1,2-ethylenediamine dihydroiodide, hydrogenated castor oil, and 1,2,3-benzotriazole into a beaker and mix, heat to a clear solution Finally, slowly stir and cool to obtain a paste mixture;

[0052] Mix the above paste mixture with 1,2-ethylenediamine dihydroiodide and WACKER model N20 fumed silica, and grind it with a three-roll mill to obtain a paste;

[0053] The paste obtained by grinding with a three-roller mill was tested with a scraper fineness meter, and...

Embodiment 2

[0054] Embodiment 2: Preparation of a kind of water-washing flux paste

[0055] Preparation of 1-(3-aminopropyl) imidazole rosin salt: 1-(3-aminopropyl) imidazole and maleic acid modified rosin are dissolved in isopropanol with a molar ratio of 1:1, after neutralization Dried.

[0056] Raw material formula: see Table 1. The preparation method is the same as in Example 1.

Embodiment 3

[0057] Embodiment 3: Preparation of a kind of water-washing flux paste

[0058] Preparation of 1-(3-aminopropyl) imidazole rosin salt: 1-(3-aminopropyl) imidazole and acrylic acid-modified rosin are dissolved in isopropanol with a molar ratio of 1:1, dried after neutralization and become.

[0059] Raw material formula: see Table 1. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com