A High Side Conductance Enhanced Power Switch Driving Circuit

A driving circuit and power switch technology, which is applied in electronic switches, output power conversion devices, electrical components, etc., can solve problems such as low hole mobility, large conduction resistance, and occupied output resistance, and achieve a simplified design method , Improving the current drive capability and reducing the on-resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

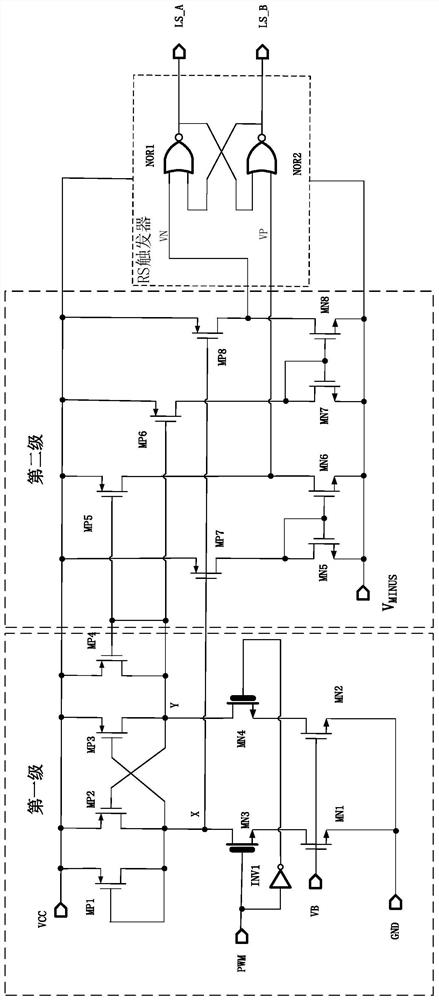

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

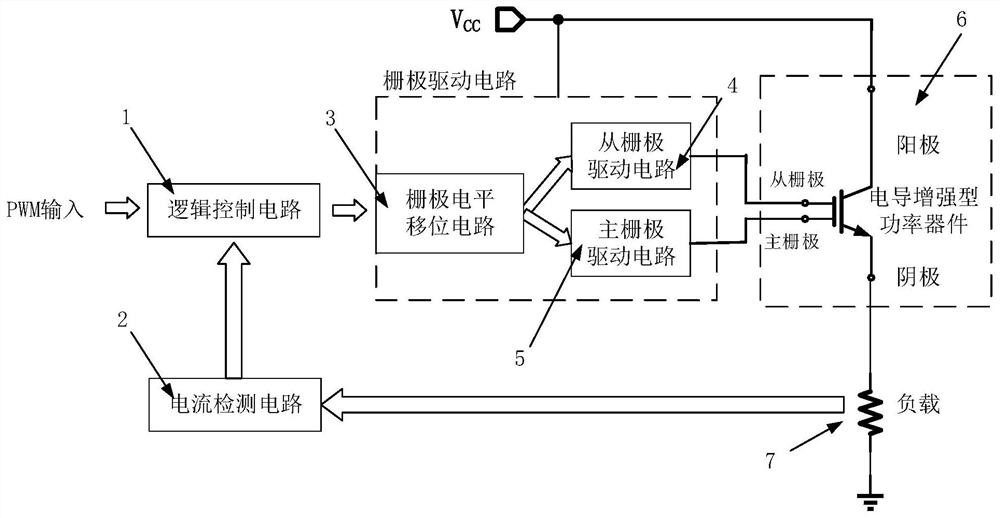

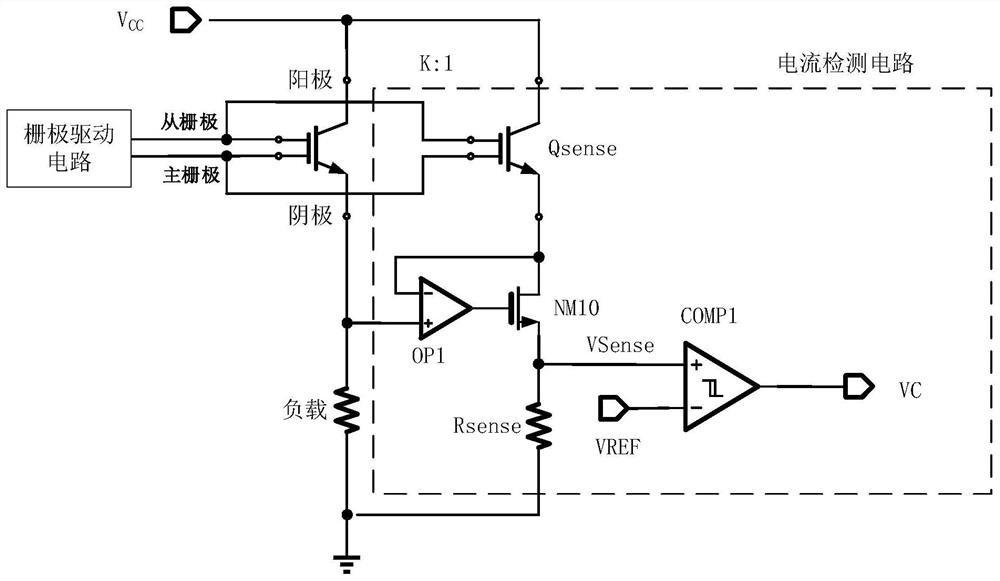

[0032] Such as figure 1 As shown, a high-side conductance-enhanced power device drive circuit includes: a conductance-enhanced power device 6, a current detection circuit 2, a logic control circuit 1, a gate level shift circuit 3, a main gate drive circuit 5, a slave Gate drive drive circuit 4, load 7 and power supply V CC .

[0033] The conductance-enhanced power device 6 has a main gate, a slave gate, an anode and a cathode, the conductance-enhanced power device main gate is connected to the output end of the main gate drive circuit, the slave gate is connected to the output end of the slave gate drive circuit, and the anode is connected to Power V CC , the cathode is grounded through the load; the conductance-enhanced power device is placed on the high side, and different operating modes are switched according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com