Reverse-flow PRMD-PRO system and method based on waste heat recovery and desalination

A waste heat recovery, countercurrent technology, applied in chemical instruments and methods, general water supply conservation, water/sewage multi-stage treatment, etc., can solve the problems of lack of advanced treatment technology for industrial wastewater, inability to directly use wastewater, and threats to human survival. Achieve the effect of alleviating membrane fouling, small footprint, and alleviating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

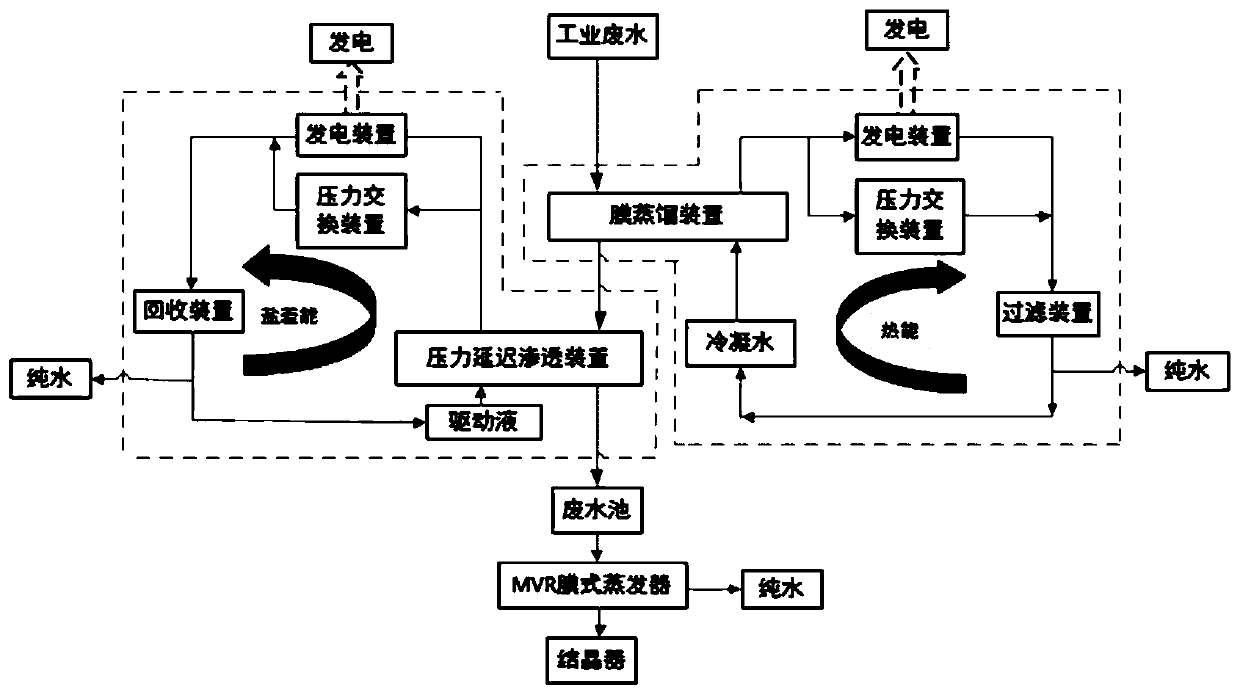

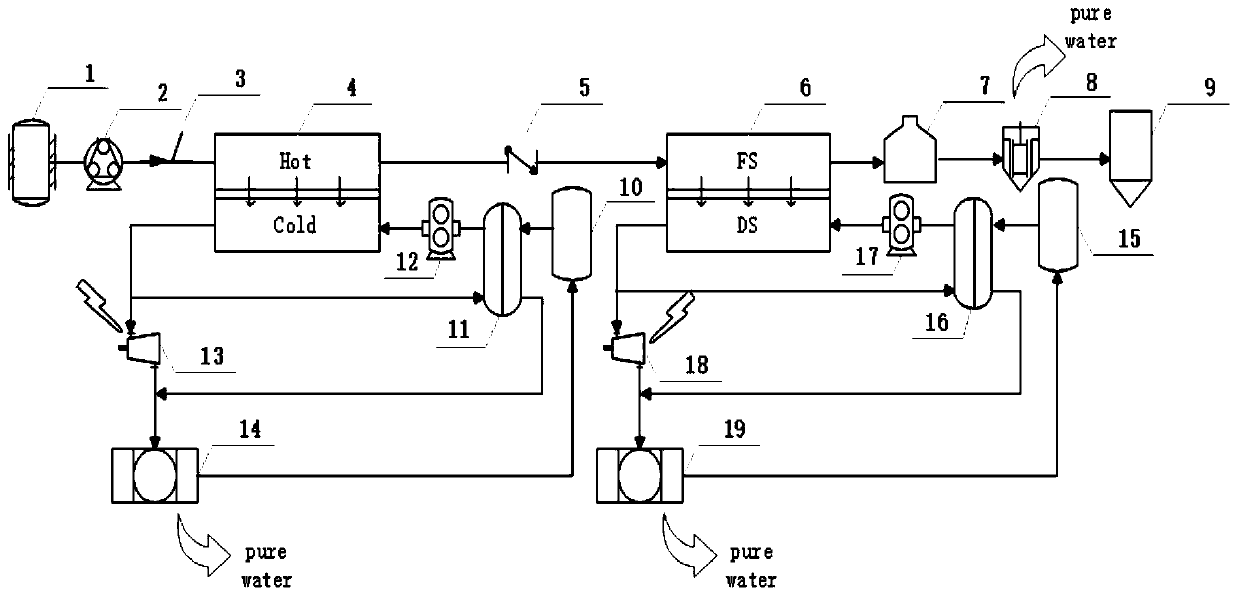

[0061] Such as figure 1 and figure 2 As shown, a countercurrent PRMD-PRO system based on waste heat recovery and desalination includes a raw material liquid pool 1, a cooling liquid pool 10, a pressure-delayed membrane distillation module 4, a pressure-delayed osmosis module 6, a first pressure exchanger 11, Coolant gear pump 12, first turbine 13, filter device 14, drive fluid pool 15, second pressure exchanger 16, drive fluid gear pump 17, second turbine 18, drive fluid recovery device 19, waste water pool 7, MVR membrane Type evaporator 8 and crystallizer 9. The outlet of the coolant pool 10 is connected to the upper inlet of the first pressure exchanger 11; the upper inlet of a pressure exchanger 11 is connected to the inlet of the coolant gear pump 12; the outlets of the raw material pool 1 and the coolant gear pump 12 are respectively connected to the pressure Two inlets on both sides of the delayed membrane distillation assembly 4; the outlet of the cooling liquid of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com