Electrolytic capacitor module, filter circuit and power converter

A technology of electrolytic capacitors and power converters, which is applied in the direction of electrolytic capacitors, capacitor electrodes, capacitors, etc., can solve the problems of large loss of aluminum electrolytic capacitors, etc., and achieve the effects of simplifying cooling components, improving ripple current tolerance, and reducing the rate of capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0068]

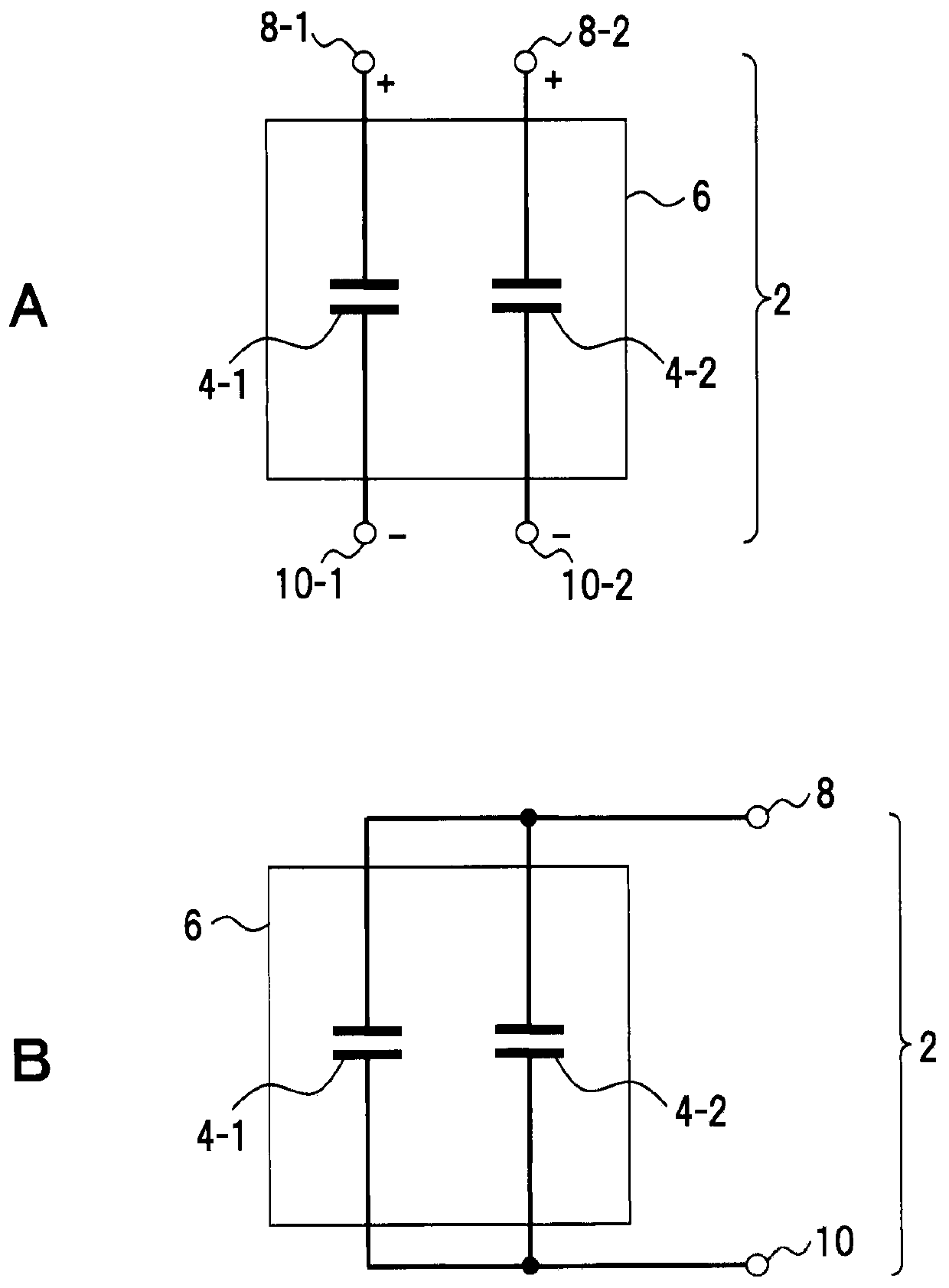

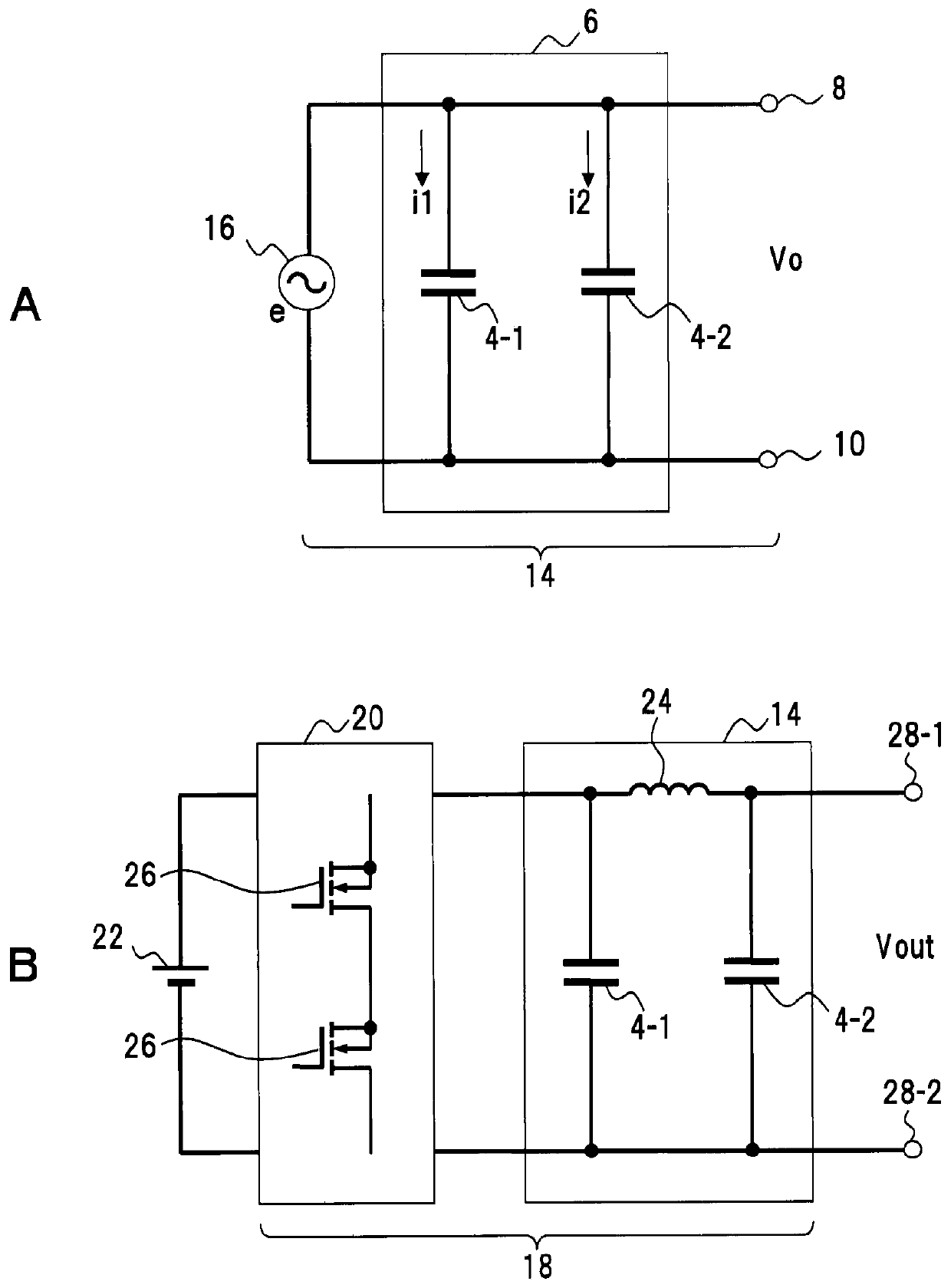

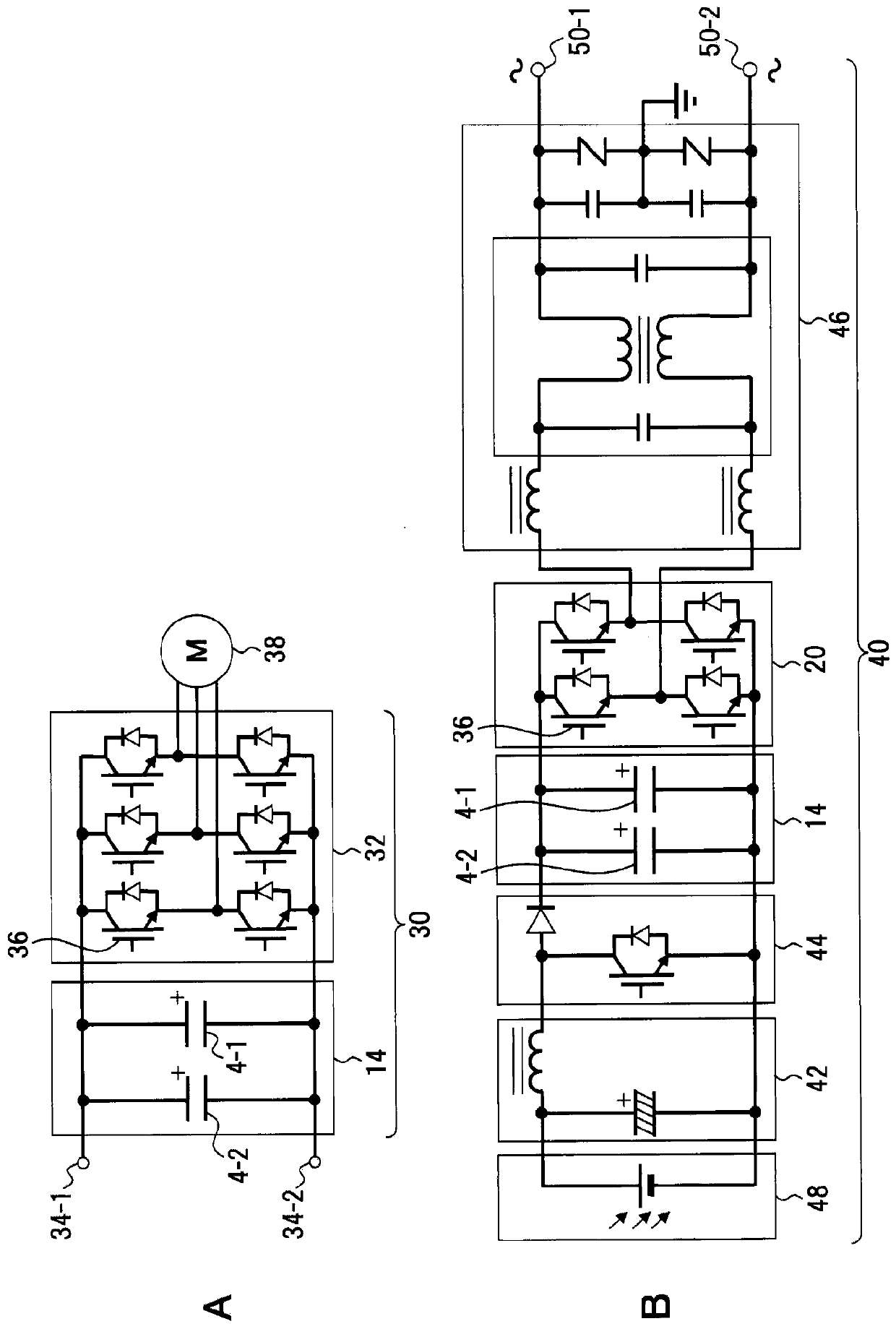

[0069] figure 1 A shows an embodiment of an electrolytic capacitor module. figure 1 The configuration shown is an example and is not limited to the configuration described above.

[0070] This electrolytic capacitor module (hereinafter simply referred to as “capacitor module”) 2 includes at least two electrolytic capacitors in which electrode foils have etching pits formed therein. These electrolytic capacitors are a first electrolytic capacitor 4-1 and a second electrolytic capacitor 4-2 as two types of electrolytic capacitors having different etch pit lengths. Here, regarding the "two types of different etching pit lengths", the length (depth) of the tunnel-shaped etching pit formed in the electrode foil of the capacitor element used in the electrolytic capacitor is called the pit length, and the pit length is used as a classification concept Classified.

[0071] In this one embodiment, the electrolytic capacitor 4 - 1 shows the case of an electrolytic capacito...

Embodiment 1~ Embodiment 4 and comparative example 1~ comparative example 4

[0194] Hereinafter, Examples 1 to 4 and Comparative Examples 1 to 4 will be described. Figure 12 The pit length, the frequency, and the electrostatic capacitance as the measurement results of the first to third times, and their average values are shown.

Embodiment 1

[0196] The capacitor element of Example 1 in which the anode foil used the electrode foil whose etching pit length=27 [μm] was manufactured.

[0197] As the electrode foil on the anode side, an aluminum foil having a size of 20 [mm]×20 [mm] and a foil thickness of 125 [μm] was used as the anode foil. The electrode foil was subjected to two-stage etching treatment. In the first-stage etching treatment, the electrode foil was dipped in an aqueous solution containing hydrochloric acid, and the aluminum foil was electrochemically etched with DC voltage to form etching pits.

[0198] In the second-stage etching treatment, the electrode foil subjected to the first-stage etching treatment is immersed in an aqueous solution containing nitric acid, and the etching treatment is performed electrochemically or chemically to expand the etching pits formed in the first-stage. The electrode foil subjected to such etching treatment was subjected to a chemical conversion treatment in an ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com