A glass nanopore sensor for detecting oh and its preparation and application

A nanopore sensor and nanopore technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult probe synthesis, low steady-state concentration, high reactivity, and achieve selectivity and sensitivity, rapid response, and economical detection. The effect of simple cost and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

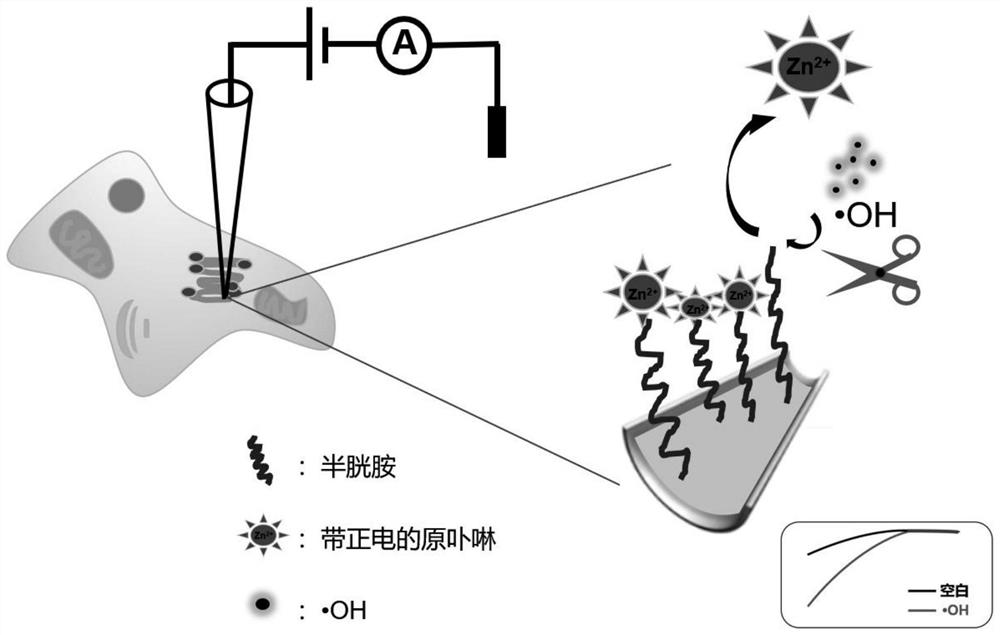

[0070] Embodiment 1 Utilizes the Fenton reaction to detect the OH produced in the aqueous solution

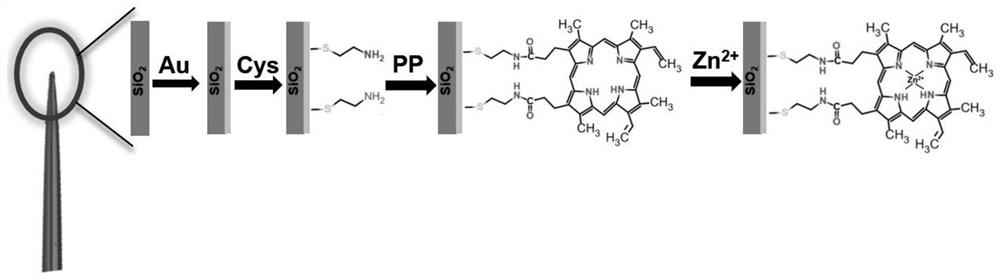

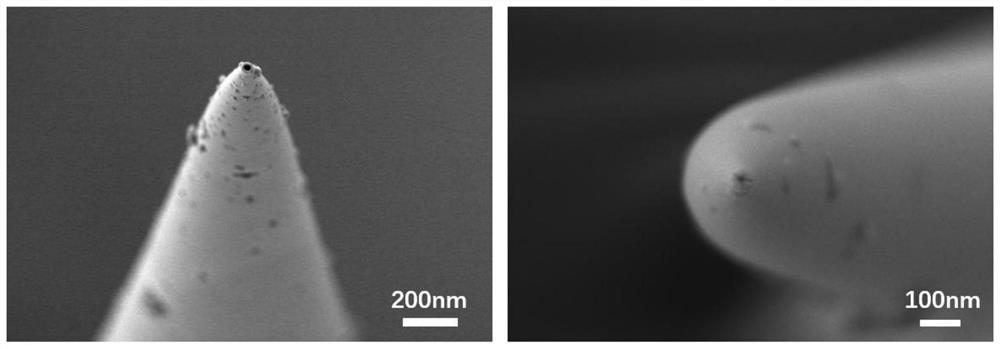

[0071] (1) Preparation of glass nanoporous sensors

[0072] Use drawing instrument to draw out aperture 70nm, the glass conical nanopore of conical nanopore angle 5 °, inject the ethanol solution (V of 8mmol / L chloroauric acid 氯金酸 :V 乙醇 =3:2) 10 μL, irradiated for 2 hours under a 254 nm ultraviolet lamp, washed the nanopore with ethanol, dried at room temperature, and baked at 100° C. for 1 hour, so that the gold film was firmly covered on the inner wall of the nanopore. Then configure 10 -2 mol / L ethanol solution of cysteamine hydrochloride, inject 10 μL into the nanopore, and let it stand at room temperature for 8 hours, so that the sulfhydryl group in the cysteamine molecule can bind to the gold film through the Au-S bond, and then wash with ethanol to remove excess or weakly bound cysteamine. Finally, take the protoporphyrin solution (10 -5 mol / L), (get commercially av...

Embodiment 2

[0078] Example 2 uses drugs to stimulate and inhibit cells, and detects OH in cells

[0079] (1) Preparation of glass nanoporous sensors

[0080] The preparation method is the same as in Example (1).

[0081] (2) Detection of OH in cells

[0082] Before detection, inject 10 into the glass nanopore sensor -4 mol / L Zn 2+ Solution, at room temperature (25°C±3°C), let it stand for 8 hours to remove unbound or weakly bound Zn 2+ solution and washed with distilled water. Then inject pH7.0 electrolyte solution (containing 0.1mol / L KCl, pH7.0, 10mmol / L HEPES buffer solution) into the hole.

[0083] RAW264.7 mouse mononuclear macrophages in cell culture medium (composition includes 10% bovine serum albumin, 100unit / mL penicillin, 100ug / mL streptomycin), 37 ℃, 5% CO 2 On the day before the test, the cells were transferred to a petri dish with a diameter of 35 mm and a height of 14 mm, allowing the cells to adhere and grow freely for 24 hours. Before the test, under a confocal mic...

Embodiment 3

[0087] Example 3 Non-destructive cell insertion experiment

[0088] (1) Preparation of glass nanoporous sensors

[0089] The preparation method is the same as in Example (1).

[0090] (2) Non-destructive cell insertion experiment

[0091] Before detection, inject 10 into the glass nanopore sensor -4 mol / L Zn 2+ Solution, at room temperature, let it stand for 8 hours, remove unbound or weakly bound Zn 2+ solution and washed with distilled water. Then inject pH7.0 electrolyte solution (containing 0.1mol / L KCl, pH7.0, 10mmol / L HEPES buffer solution) into the hole.

[0092] In this example, Hela cells were used, and the culture method was the same as that of the mouse mononuclear macrophage RAW264.7 in Example 2. Before the experiment, the cells were stained with fluorescent dyes: Calcein-AM was used to stain live cells and PI was used to stain dead cells. Insert the glass nanopore sensor into the cell for 15 minutes and then take it out, and compare the changes in the numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com