Efficient raw material disinfection device for textile processing

A disinfection device and high-efficiency technology, which is applied in the direction of processing textile material equipment configuration, processing textile material carrier, disinfection, etc., can solve the problems of affecting the quality of fabrics, increasing the production process of drying and drug removal, and achieve the effect of improving the dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

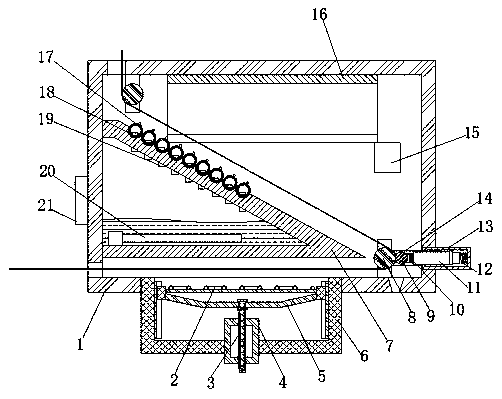

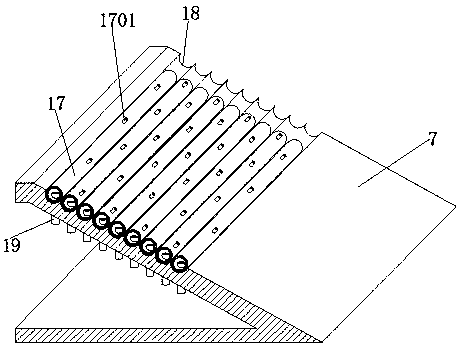

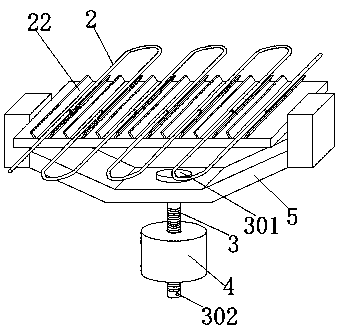

[0030] refer to Figure 1-5 , a high-efficiency disinfection device for raw materials for textile processing, comprising a box body 1 with a cavity in a cuboid structure, the top inner wall and the bottom inner wall of the box body 1 are provided with conveying rollers 8 near the diagonals, and the rollers of the conveying rollers 8 The outer wall of the body is wound with the same cloth body, and the inner wall of the box body 1 is provided with a steam box 7 near the bottom of the cloth body, and the upper surface of the steam box 7 is provided with an inclined plane consistent with the inclination angle of the cloth body, and there are equidistant Distributed arc-shaped grooves 18, and the bottom of the arc-shaped grooves 18 are clamped with steam nozzles 17, and the outer wall of the steam nozzles 17 is connected with a connecting pipe 19 connected to the inside of the steam box 7 near the middle. The inner diameter of the connecting pipe 19 is getting bigger and bigger fr...

Embodiment 2

[0039] refer to Figure 1-3 , a high-efficiency disinfection device for raw materials for textile processing. Compared with Embodiment 1, this embodiment also includes a water collecting plate 16 with an arc-shaped structure with an opening downward fixed on the top inner wall of the box body 1, and the water collecting plate 16 A sump 1601 is fixed on the inner edge of the bottom.

[0040] Wherein, a water collecting bucket 15 is fixed on the lower surface of the end of the water collecting tank 1601, and the water collecting bucket 15 communicates with the inside of the steam box 7 through a water diversion pipe.

[0041] Working principle: When in use, after the water vapor discharged from the nozzle on the steam nozzle is pre-cooled and liquefied, it will flow along the inner wall of the water collecting plate 16 to the water collecting tank 1601 at the bottom for unified collection, so as to avoid water droplets falling Cloth body to reduce the later drying speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com