A kind of recycling method of waste lithium iron phosphate battery cathode material

A technology for lithium iron phosphate batteries and positive electrode materials, applied in battery recycling, recycling technology, battery electrodes, etc., can solve problems such as long process, achieve low cost, simple process, and improve the effect of recycling economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

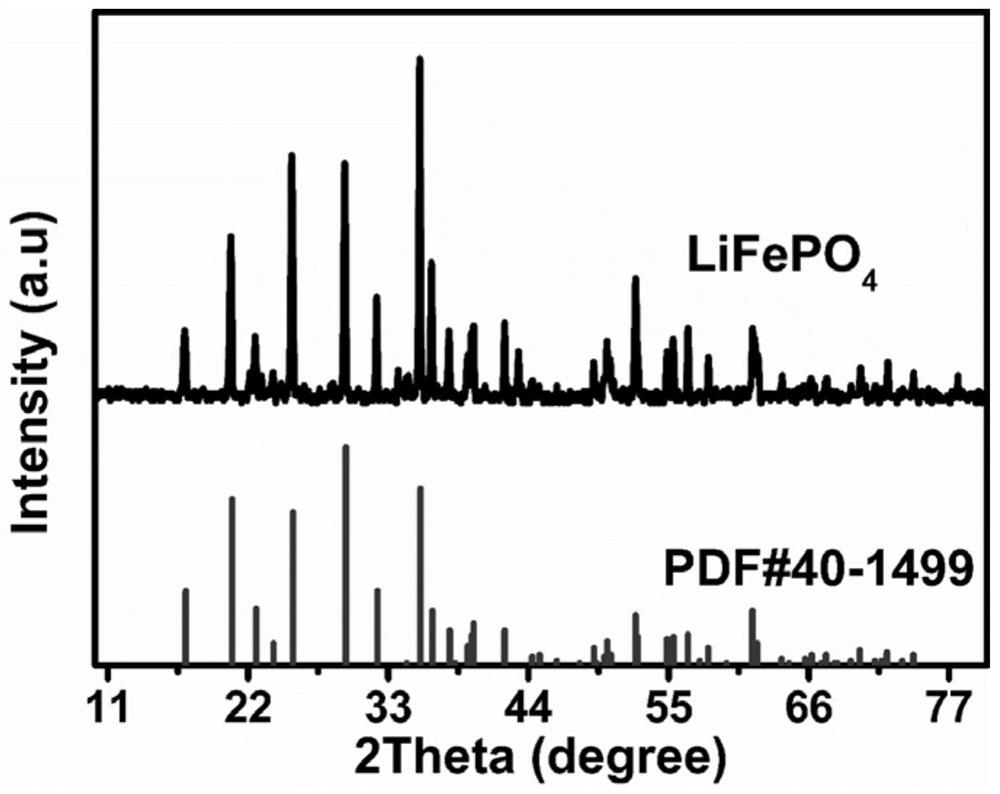

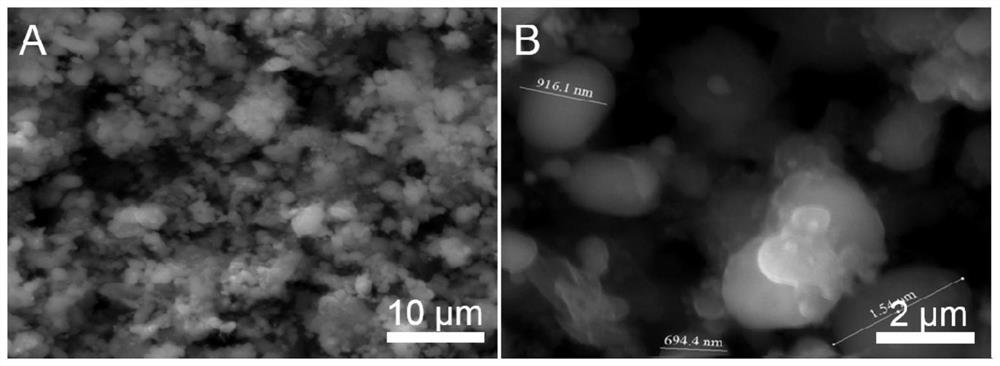

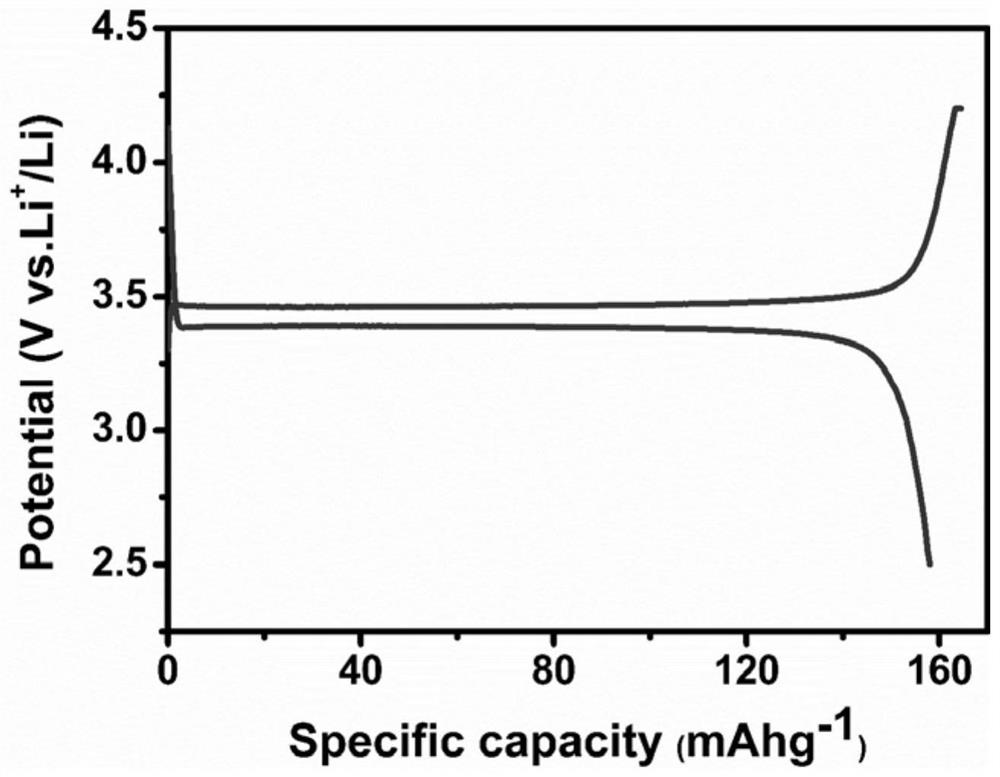

Image

Examples

Embodiment 1

[0025] 1) Disassemble the waste lithium iron phosphate battery, collect the positive electrode sheet and cut the positive electrode sheet into 1cm*1cm block electrode sheet, soak in 8mol / L sodium hydroxide solution to completely dissolve the aluminum foil, and then filter , drying the collected filter residue at 80°C for 8 hours to obtain lithium iron phosphate powder;

[0026] 2) Dissolve pyrophosphoric acid in water to prepare a 0.5mol / L pyrophosphoric acid solution; add the powder obtained in step 1) into the pyrophosphoric acid solution, control the concentration of lithium iron phosphate powder to 200g / L, and stir at room temperature React for 9 hours, then place it for 12 days; then filter the material, collect the filter residue and filtrate respectively; wherein the filter residue is a solid mainly composed of iron phosphate, and the filtrate is a solution containing lithium ions;

[0027] 3) prepare lithium hydroxide product by existing routine process with step 2) ga...

Embodiment 2

[0032] 1) Disassemble the waste lithium iron phosphate battery, collect the positive electrode sheet and cut the positive electrode sheet into 1cm*1cm block electrode sheet, soak in 8mol / L sodium hydroxide solution to completely dissolve the aluminum foil, and then filter , drying the collected filter residue at 80°C for 9 hours to obtain lithium iron phosphate powder;

[0033] 2) Dissolve pyrophosphoric acid in water to prepare a 2.5mol / L pyrophosphoric acid solution; add the powder obtained in step 1) into the pyrophosphoric acid solution, control the concentration of lithium iron phosphate powder to 100g / L, and stir at room temperature React for 7 hours, then place it for 8 days; then filter the material, collect the filter residue and filtrate respectively; wherein the filter residue is a solid mainly composed of iron phosphate, and the filtrate is a solution containing lithium ions;

[0034] 3) prepare lithium carbonate product by existing routine process with step 2) gai...

Embodiment 3

[0039] 1) Disassemble the waste lithium iron phosphate battery, collect the positive electrode sheet and cut the positive electrode sheet into 1cm*1cm block electrode sheet, soak in 8mol / L sodium hydroxide solution to completely dissolve the aluminum foil, and then filter , drying the collected filter residue at 80°C for 6 hours to obtain lithium iron phosphate powder;

[0040] 2) Dissolve pyrophosphoric acid in water to prepare a 1.5mol / L pyrophosphoric acid solution; add the powder obtained in step 1) into the pyrophosphoric acid solution, control the concentration of lithium iron phosphate powder to 80g / L, and stir at room temperature React for 10 hours, then place it for 12 days; then filter the material, collect the filter residue and filtrate respectively; wherein the filter residue is a solid mainly composed of iron phosphate, and the filtrate is a solution containing lithium ions;

[0041] 3) prepare lithium carbonate product by existing routine process with step 2) ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com