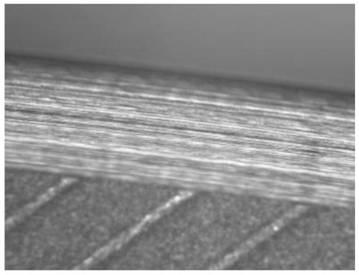

Diamond grinding wheel for precise grinding of semiconductor substrate chamfering

A diamond grinding wheel, precision grinding technology, applied in grinding devices, grinding/polishing equipment, abrasives, etc., can solve the problems of expensive imported grinding wheels, shutdown of semiconductor companies, and untimely after-sales service, and achieve good self-sharpening. , Good processing performance, consistent wear resistance and sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a kind of preparation method of described precision grinding diamond grinding wheel, comprises the steps:

[0043] (1) Mix the binder and diamond mechanically for 0.5 to 1.5 hours, and then put it into the mold cavity;

[0044] (2) Place the mold of step (1) in a sintering hot press under a nitrogen atmosphere to protect sintering, the sintering temperature is 700-1000°C, the sintering time is 1-2h, and the hot-pressing pressure is 50-100T;

[0045] (3) Process the material obtained in step (2) to a specified qualified shape and size on a lathe and a grinder, pack it, and put it into storage to obtain the grinding wheel.

[0046] Preferably, the preparation method of the diamond grinding wheel for precision grinding comprises the steps of:

[0047] (1) Mix the binder with the diamond machine for 1 hour, and then put it into the mold cavity;

[0048] (2) Put the mold of step (1) in a sintering hot press under nitrogen...

Embodiment 1

[0053] Embodiment 1 of the present invention provides a diamond grinding wheel for precision grinding, comprising the following raw materials in parts by weight: 230 parts of adhesive and 50 parts of diamond;

[0054] The binder includes cobalt powder, iron powder, silver powder and copper-tin alloy powder; the weight ratio of the cobalt powder, iron powder, silver powder and copper-tin alloy powder is 1:0.12:0.05:0.25;

[0055] Copper-tin alloy powder is spherical copper-tin alloy powder, 8020 copper-tin alloy powder;

[0056] The iron powder is hydroxyl iron powder, the model is YZ;

[0057] The particle diameter of described binding agent is 1800 orders;

[0058] The preparation method of the adhesive is as follows: first mechanically mix cobalt powder, iron powder, silver powder and copper-tin alloy powder for 1.5 hours, and then pass it through a 2000-mesh screen to obtain the required 2000-mesh adhesive;

[0059] Diamond is a diamond material with uniform particle size...

Embodiment 2

[0066] Embodiment 2 of the present invention provides a diamond grinding wheel for precision grinding, comprising the following raw materials in parts by weight: 380 parts of adhesive and 80 parts of diamond;

[0067] The binder includes cobalt powder, iron powder, silver powder and copper-tin alloy powder; the weight ratio of the cobalt powder, iron powder, silver powder and copper-tin alloy powder is 1:0.35:0.0.19:0.66;

[0068] Copper-tin alloy powder is spherical copper-tin alloy powder, 8020 copper-tin alloy powder;

[0069] The iron powder is hydroxyl iron powder, the model is YZ;

[0070] The particle diameter of described binder is 2100 meshes;

[0071] The preparation method of the adhesive is as follows: first mechanically mix cobalt powder, iron powder, silver powder and copper-tin alloy powder for 1.5 hours, and then pass it through a 2000-mesh screen to obtain the required 2000-mesh adhesive;

[0072] Diamond is a diamond material with uniform particle size dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com