Conductive crosslinked polyethylene composite material and preparation method thereof

A technology of cross-linked polyethylene and composite materials, which is applied in the field of conductive cross-linked polyethylene composite materials and its preparation, can solve the problems of easy fracture of carbon nanotubes, low conductive threshold, poor dispersion of carbon nanotubes, etc., and achieve industrialization Operation, high quality and high yield, and the effect of keeping the shape intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

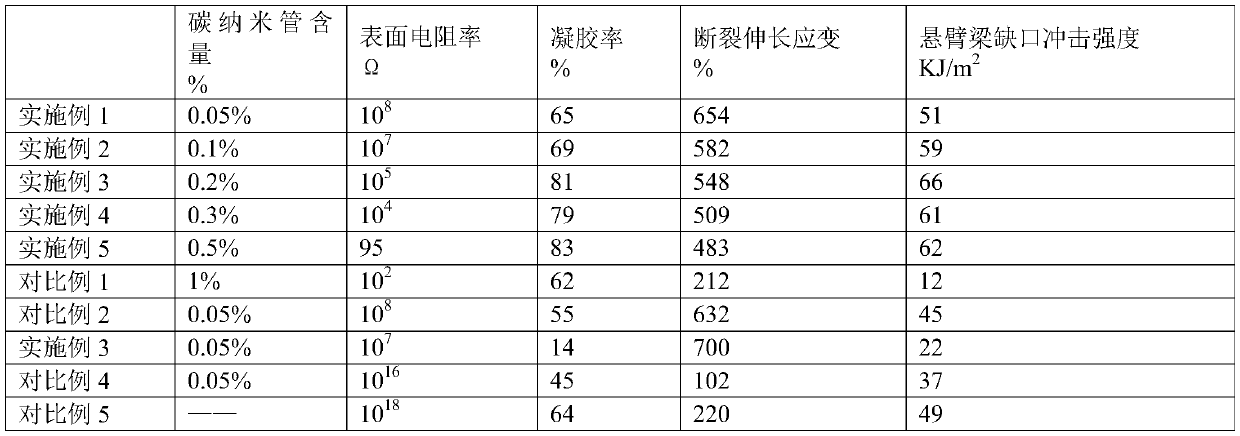

Examples

Embodiment 1

[0034] The preparation method of the conductive cross-linked polyethylene composite material, the preparation process is carried out according to the following steps:

[0035] a) 0.05Kg single-walled carbon nanotubes, 1Kg neodecyl tert-amyl peroxide and 7.95Kg triallyl cyanurate were mixed, stirred at 50° C., and ultrasonically dispersed for 90 minutes; the diameter of the carbon nanotubes was 0.5-500nm, aspect ratio ≥ 100.

[0036] b) When the temperature of the system is lowered to 40°C, add 1Kg of peroxide B2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and stir for 3 minutes to prepare a suspension of carbon nanotubes;

[0037] c) Grinding the polyethylene into powder in a plastic mill, so that the particle size of the polyethylene powder is D95≤1mm;

[0038] d) Place 90Kg of polyethylene powder in a mixer equipped with a heating mantle, heat to 40°C, pour 10Kg of carbon nanotube suspension at 40°C, and keep stirring for 10 minutes to obtain the finished product.

[0039] ...

Embodiment 2

[0041] The preparation method of the conductive cross-linked polyethylene composite material, the preparation process is carried out according to the following steps:

[0042] a) Mix 0.1Kg single-walled carbon nanotubes, 1.0Kg isopropyl peroxydicarbonate, 0.2Kg ditetradecyl peroxydicarbonate, and 7.2Kg diallyl terephthalate at 54°C Stirring is carried out, and ultrasonic dispersion is carried out for 100 minutes at the same time; the diameter of carbon nanotubes is 0.5-500nm, and the aspect ratio is ≥100.

[0043] b) When the temperature of the system is lowered to 44° C., add 1.5 Kg of di-tert-amyl peroxide, and stir for 3.5 minutes to prepare a suspension of carbon nanotubes;

[0044] c) Grinding the polyethylene into powder in a plastic mill, so that the particle size of the polyethylene powder is D95≤1mm;

[0045]d) Place 92Kg of polyethylene powder in a mixer equipped with a heating mantle, heat to 45°C, pour 8Kg of carbon nanotube suspension at 45°C, keep stirring for 1...

Embodiment 3

[0048] The preparation method of the conductive cross-linked polyethylene composite material, the preparation process is carried out according to the following steps:

[0049] a) Mix 0.2Kg single-walled carbon nanotubes, 1.4Kg (2-ethylhexyl) peroxydicarbonate and 6.4Kg triallyl cyanurate, stir at 60°C, and ultrasonically disperse for 105min at the same time ; The carbon nanotube diameter is 0.5-500nm, and the aspect ratio is ≥100.

[0050] b) When the temperature of the system is lowered to 40-60°C, add 1Kg of tert-amyl peroxybenzoate and 1Kg of dicumyl peroxide, and stir for 4 minutes to prepare a suspension of carbon nanotubes;

[0051] c) Grinding the polyethylene into powder in a plastic mill, so that the particle size of the polyethylene powder is D95≤1mm;

[0052] d) Place 94Kg of polyethylene powder in a mixer equipped with a heating mantle, heat to 50°C, pour 6Kg of carbon nanotube suspension at 50°C, keep it warm and stir for 25min to obtain the finished product.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com