GSP film material for solar photo-thermal steam conversion and preparation method thereof

A film material, solar energy technology, applied in the steam generation method using solar energy, parts of solar collectors, solar thermal energy, etc., can solve the problems of low solar light absorption rate, low photothermal conversion efficiency, etc. efficiency, improving photothermal conversion efficiency, good toughness and filtering water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

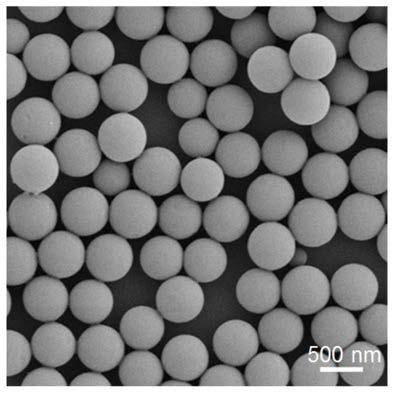

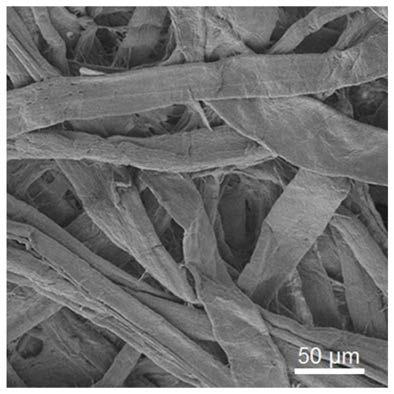

[0056] (1) Take 0.5g of γ-mercaptopropyltrimethoxysilane in 200mL of water, stir mechanically at 200 rpm until the solution is clear and transparent, then adjust the pH to about 9 with ammonia water, continue to stir mechanically for 12 hours, and the solution changes from a transparent solution to a Milky white solution, then centrifuge at 3000 rpm to remove the supernatant, add deionized water to wash 5 times, freeze in liquid nitrogen at -196°C, dry under 10 Pa vacuum condition for 24 h to obtain white silicone pellet powder, and set aside;

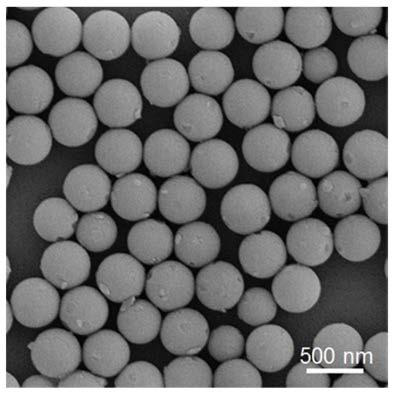

[0057] (2) Weigh 0.5 g of silicone pellets, disperse them uniformly in 50 mL of water, and then add 100 μL of 0.25 mol L -1 The solution was ultrasonically reacted until the color no longer changed, then centrifuged at 3000 rpm to remove the supernatant, and dried under 10 Pa vacuum for 12 h to obtain gold-complexed organosilicon pellet powder;

[0058] (3) Put the gold-complexed silicone pellet powder in a quartz boat, put it into a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com