Sodium alginate microspheres of coenzyme Q10 and preparation method thereof

A sodium alginate and coenzyme technology, applied in the chemical field, can solve the problems of coenzyme Q10 drug loading, encapsulation efficiency and stability, etc., to improve drug loading and encapsulation efficiency, which is conducive to wide application and storage long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

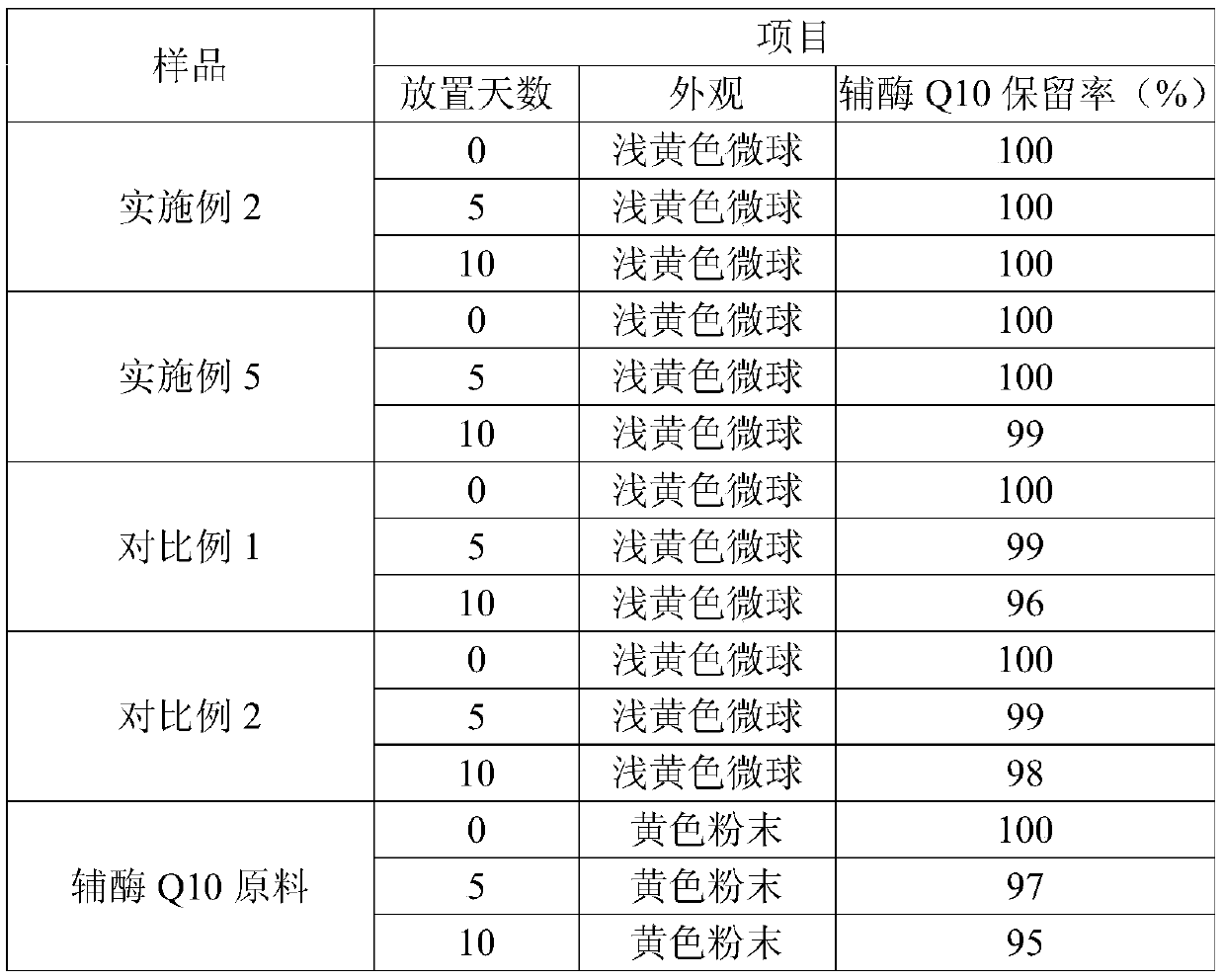

Examples

Embodiment 1

[0047] Embodiment 1, the preparation of the sodium alginate microsphere of coenzyme Q10

[0048] In this embodiment, the sodium alginate microspheres of coenzyme Q10 include the following raw materials in weight percentage: 40 wt% of coenzyme Q10, 30 wt% of cyclodextrin, and 30 wt% of sodium alginate.

[0049] The preparation method of the sodium alginate microspheres of the coenzyme Q10 of the present embodiment comprises the following steps:

[0050](1) Weigh 20g of coenzyme Q10, heat to 50°C to form a coenzyme Q10 melt; weigh 15g of sodium alginate, dissolve it in 200g of water, and heat to 50°C to completely dissolve the sodium alginate to form a sodium alginate solution; Weigh 5g of calcium chloride and dissolve it in 250g of water to form an aqueous solution of calcium chloride; weigh 15g of β-cyclodextrin, add it to 300g of water, put it in a high-speed shearing machine, and heat it to 75°C to make β-cyclodextrin The alcohol is completely dissolved to form an aqueous s...

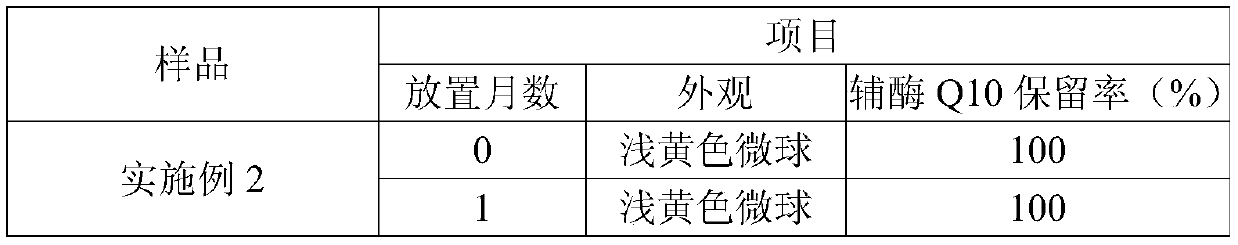

Embodiment 2

[0055] Embodiment 2, the preparation of the sodium alginate microsphere of coenzyme Q10

[0056] In this embodiment, the sodium alginate microspheres of coenzyme Q10 include the following raw materials in weight percentage: coenzyme Q10 10wt%, cyclodextrin 30wt%, sodium alginate 60wt%.

[0057] The preparation method of the sodium alginate microspheres of the coenzyme Q10 of the present embodiment comprises the following steps:

[0058] (1) Weigh 5g of coenzyme Q10, heat to 50°C to form a coenzyme Q10 melt; weigh 30g of sodium alginate, dissolve it in 300g of water, and heat to 60°C to completely dissolve the sodium alginate to form a sodium alginate solution; Weigh 30g of calcium chloride, dissolve it in 300g of water to form an aqueous solution of calcium chloride; weigh 15g of β-cyclodextrin, add it to 450g of water, put it into a high-speed shearing machine, and heat it to 50°C to make β-cyclodextrin The alcohol is completely dissolved to form an aqueous solution of β-cyc...

Embodiment 3

[0063] Embodiment 3, the preparation of the sodium alginate microsphere of coenzyme Q10

[0064] In this embodiment, the sodium alginate microspheres of coenzyme Q10 include the following raw materials in weight percentage: coenzyme Q10 10wt%, cyclodextrin 60wt%, and sodium alginate 30wt%.

[0065] The preparation method of the sodium alginate microspheres of the coenzyme Q10 of the present embodiment comprises the following steps:

[0066] (1) Weigh 5g of coenzyme Q10, heat to 50°C to form a coenzyme Q10 melt; weigh 15g of sodium alginate, dissolve it in 200g of water, and heat to 50°C to completely dissolve the sodium alginate to form a sodium alginate solution; Weigh 8g of calcium chloride and dissolve it in 350g of water to form an aqueous solution of calcium chloride; weigh 30g of β-cyclodextrin, add it to 500g of water, put it in a high-speed shearing machine, and heat it to 60°C to make β-cyclodextrin The alcohol is completely dissolved to form an aqueous solution of β...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com