Coating prepared from by-products in production of coal pitch-based carbon material and method thereof

A technology of carbon materials and coal tar pitch, which is applied in the field of coatings prepared by by-products, can solve the problems of waste of raw materials, manufacturing costs, and compatibility troubles with epoxy asphalt, etc., achieve good waterproofing, improve brittleness and easy cracking, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

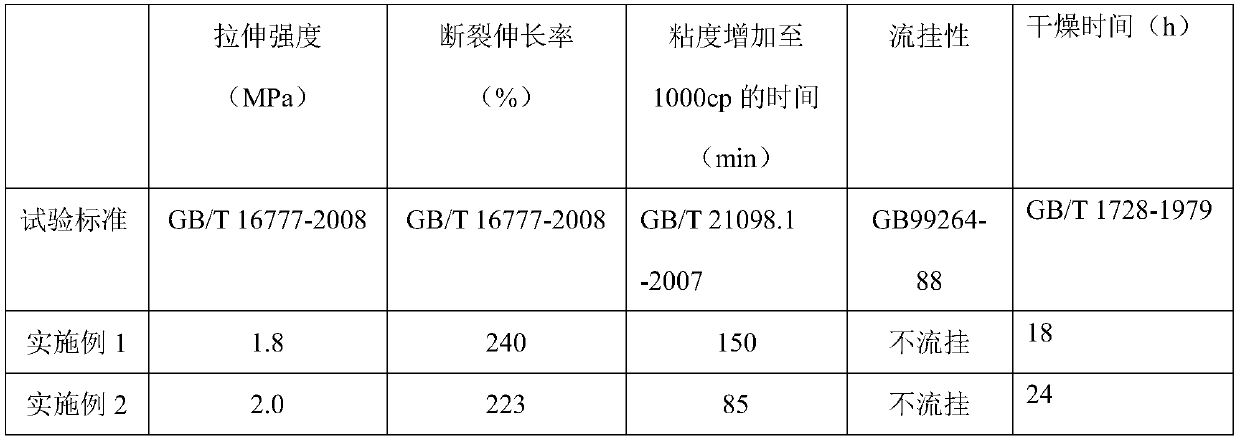

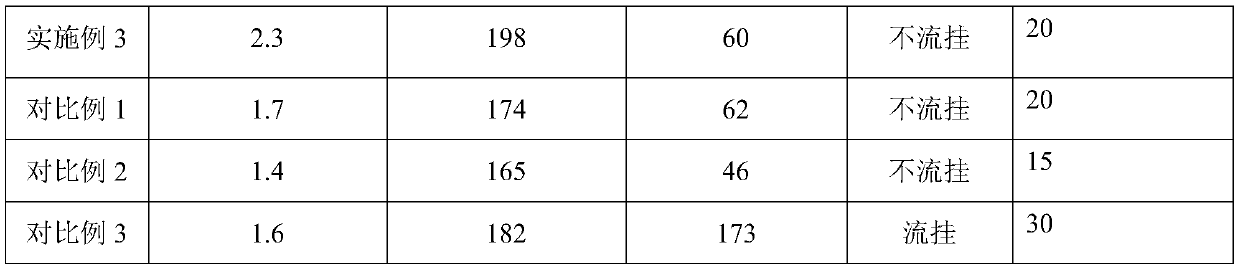

Embodiment 1

[0021] Melt and dehydrate medium temperature coal tar pitch at 100°C, dissolve and filter with toluene solvent to obtain toluene soluble pitch (toluene content 10%), take 50g of toluene soluble pitch and melt it at 50°C after dehydration, add 5g of ZnO powder, asbestos 5g of powder, 5g of chopped carbon fiber with a length of 10mm, 20g of epoxy 269 resin, mixed evenly, as component A. During construction, add 3g of DA-134 ketimine curing agent as component B, and stir evenly to obtain a coating prepared by using the by-products in the production of coal tar pitch-based carbon materials.

Embodiment 2

[0023] Melt and dehydrate high-temperature coal tar pitch at 150°C, dissolve and filter with toluene solvent to obtain toluene-soluble pitch (toluene content 20%), take 65g of toluene-soluble pitch, add 4g of ZnO powder, 3g of asbestos powder in sequence, and a length of 5mm Chopped carbon fiber 5g, epoxy 269 resin 25g, mixed evenly, as A component. During construction, add 5 g of DA-315 ketimine curing agent as component B, stir evenly, and obtain a coating prepared by using the by-products in the production of coal tar pitch-based carbon materials.

Embodiment 3

[0025] Melt and dehydrate medium-temperature coal tar pitch at 100°C, dissolve and filter with toluene solvent to obtain toluene-soluble pitch (15% toluene content), take 70g of this toluene-soluble pitch, heat it to 100°C, and add 3g of ZnO powder and asbestos powder in sequence 8g, 5g of chopped carbon fiber with a length of 10mm, 25g of epoxy 269 resin, mixed evenly, as component A. During construction, add 4 g of DA-134 ketimine curing agent as component B, stir evenly, and obtain a coating prepared by using the by-products in the production of coal tar pitch-based carbon materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com