Short-term degradable magnesium alloy material for uterine cavity stent and preparation method

A technology of magnesium alloy and uterine cavity, which is applied in the field of short-term degradable magnesium alloy material and preparation of uterine cavity stent, which can solve the problem of non-degradable uterine cavity stent, achieve excellent biocompatibility, reduce use, and reduce physical pain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

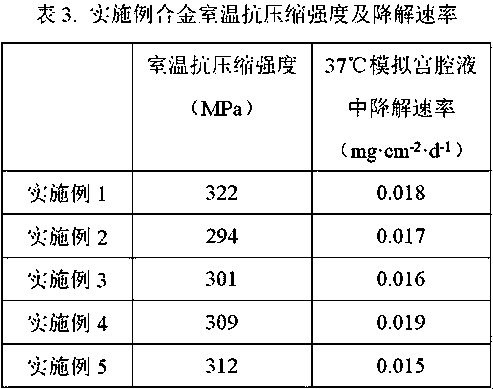

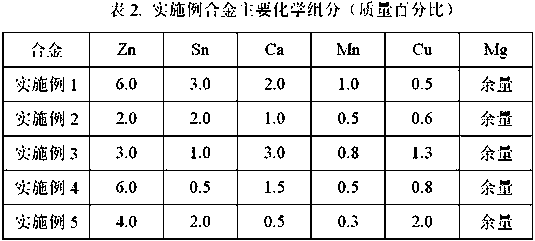

Embodiment 1

[0019] The short-term degradable magnesium alloy for preparing uterine cavity stent, its raw material composition and its weight percentage content are: Zn: 6%, Sn: 3%, Ca: 2%, Mn: 1.0%, Cu: 0.5%, and the rest is Mg and unavoidable impurity elements.

[0020] The preparation method of the short-term degradable magnesium alloy for the preparation of the uterine cavity bracket: firstly, the crucible is heated to 530°C, and pure magnesium, pure zinc, and pure tin are put into the crucible of the melting furnace, and a protective atmosphere is introduced at the same time; when the furnace temperature rises to 700 Above ℃, after all the furnace materials are melted, add the remaining metal, stir for two minutes, and keep warm for 15 minutes; after that, keep the preset time, remove the oxide on the surface, and cast into the iron mold metal mold preheated to 280℃. remain balanced.

Embodiment 2

[0022] The short-term degradable magnesium alloy for preparing uterine cavity stent, the preferred raw material composition and its weight percentage content are: Zn: 5%, Sn: 2%, Ca: 1%, Mn: 0.5%, Cu: 0.6%, and the rest is Mg and inevitable impurity elements.

[0023] The preparation method of the short-term degradable magnesium alloy for the preparation of the uterine cavity bracket: firstly, the crucible is heated to 540°C, and pure magnesium, pure zinc, and pure tin are put into the crucible of the melting furnace, and a protective atmosphere is introduced at the same time; when the furnace temperature rises to 720 ℃, after the furnace charge is completely melted, add the remaining metal, stir for two minutes, and keep warm for 10 minutes; after that, keep the preset time, remove the oxide on the surface, and cast it into the iron mold metal mold preheated to 250°C. smooth.

Embodiment 3

[0025] The short-term degradable magnesium alloy for preparing uterine cavity stent, its raw material composition and its weight percentage content are: Zn: 3.0%, Sn: 1.0%, Ca: 3.0%, Mn: 0.8%, Cu: 1.3%, and the rest is Mg and unavoidable impurity elements.

[0026] The preparation method of the short-term degradable magnesium alloy for the preparation of the uterine cavity bracket: firstly, the crucible is heated to 570°C, and pure magnesium, pure zinc, and pure tin are put into the crucible of the melting furnace, and a protective atmosphere is introduced at the same time; when the furnace temperature rises to 710 ℃, after the furnace charge is completely melted, add the remaining metal, stir for two minutes, and keep warm for 20 minutes; after that, keep the preset time, remove the oxide on the surface, and cast it into the iron mold metal mold preheated to 300°C. smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com