Titanium/nickel alloy parts and preparation method based on explosive welding and laser additive manufacturing

A laser additive and nickel alloy technology, applied in laser welding equipment, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as limiting the application of alloy products, achieve connection and free forming, good application prospects, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

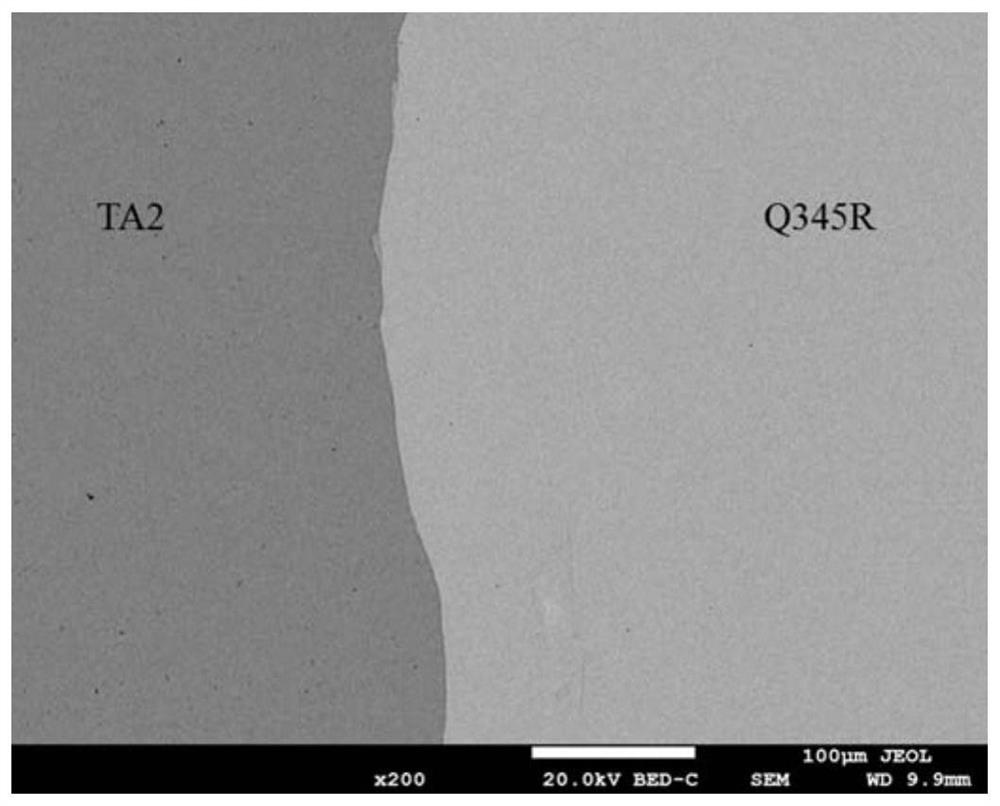

[0033] A titanium / nickel alloy preparation method based on explosive welding and laser additive manufacturing was used to prepare the TA15 / GH4169 double alloy, such as figure 1 As shown, the middle composite plate 1 adopts TA2 / Q345R.

[0034] This embodiment includes the following steps:

[0035] 1) The TA2 / Q345R composite plate is prepared by explosive welding, the surface of the Q345R steel plate 5 is polished to remove dirt and oxide film, the TA2 titanium plate 4 is preset on the steel plate, and the distance between the titanium plate 4 and the steel plate 5 is 4 mm; ammonium nitrate is used As an explosive, the detonation velocity of the explosive is 1500m / s, and the amount of explosive is 1.0g / cm -2 ;Arrange the explosives on the titanium plate and detonate through the detonator. The thickness of the TA2 plate and the Q345R plate are both 1mm;

[0036] 2) Use No. W14 metallographic sandpaper to grind both sides of the composite board to remove the oxide layer and othe...

Embodiment 2

[0046] The titanium / nickel double alloy preparation method based on explosive welding and laser additive manufacturing was used to prepare the TC4 / GH4169 double alloy, and the intermediate composite plate was made of TA1 / N6.

[0047] This embodiment includes the following steps:

[0048] 1) The TA1 / N6 composite plate was prepared by explosive welding, the surface of the N6 plate was polished to remove dirt and oxide film, and the titanium plate TA1 was preset on the nickel plate with a distance of 6 mm; ammonium nitrate was used as the explosive, and the detonation velocity of the explosive was 2000m / s, the amount of explosive is 1.5g / cm -2 ;Arrange the explosives on the titanium plate and detonate through the detonator. The thickness of the TA1 plate and the N6 plate are both 2mm;

[0049] 2) Use No. W14 metallographic sandpaper to grind both sides of the composite board to remove the oxide layer and other impurities, and then put the composite board into 99% alcohol for ult...

Embodiment 3

[0058] The titanium / nickel double alloy preparation method based on explosive welding and laser additive manufacturing was used to prepare the TA15 / GH4033 double alloy, and the intermediate composite plate was TA2 / Q235B.

[0059] This embodiment includes the following steps:

[0060] 1) The TA2 / Q235B composite plate is prepared by explosive welding, the surface of the Q235B steel plate is polished to remove dirt and oxide film, and a TA2 titanium plate is preset on the steel plate with a distance of 6mm; ammonium nitrate is used as the explosive, and the detonation velocity of the explosive is 2500m / s, the amount of explosive is 2.0g / cm -2 ;Arrange the explosives on the titanium plate and detonate through the detonator. The thickness of the TA2 plate and the Q235B plate are both 3mm;

[0061] 2) Use No. W14 metallographic sandpaper to grind both sides of the composite board to remove the oxide layer and other impurities, and then put the composite board into 99% alcohol for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com