Halogen-free flame-retardant polycarbonate alloy resistant to cold and hot alternation and preparation method thereof

A flame retardant polycarbonate and polycarbonate technology, which is applied in the field of halogen-free flame retardant polycarbonate alloy and its preparation, can solve the problems of insufficient dense intermolecular stacking, poor processing fluidity, stress cracking, etc., and achieves improved dispersion and distribution. effect, ensure processing fluidity, and improve the effect of flame retardant stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a halogen-free flame retardant polycarbonate alloy resistant to alternating cold and heat and a preparation method thereof. The specific steps are as follows:

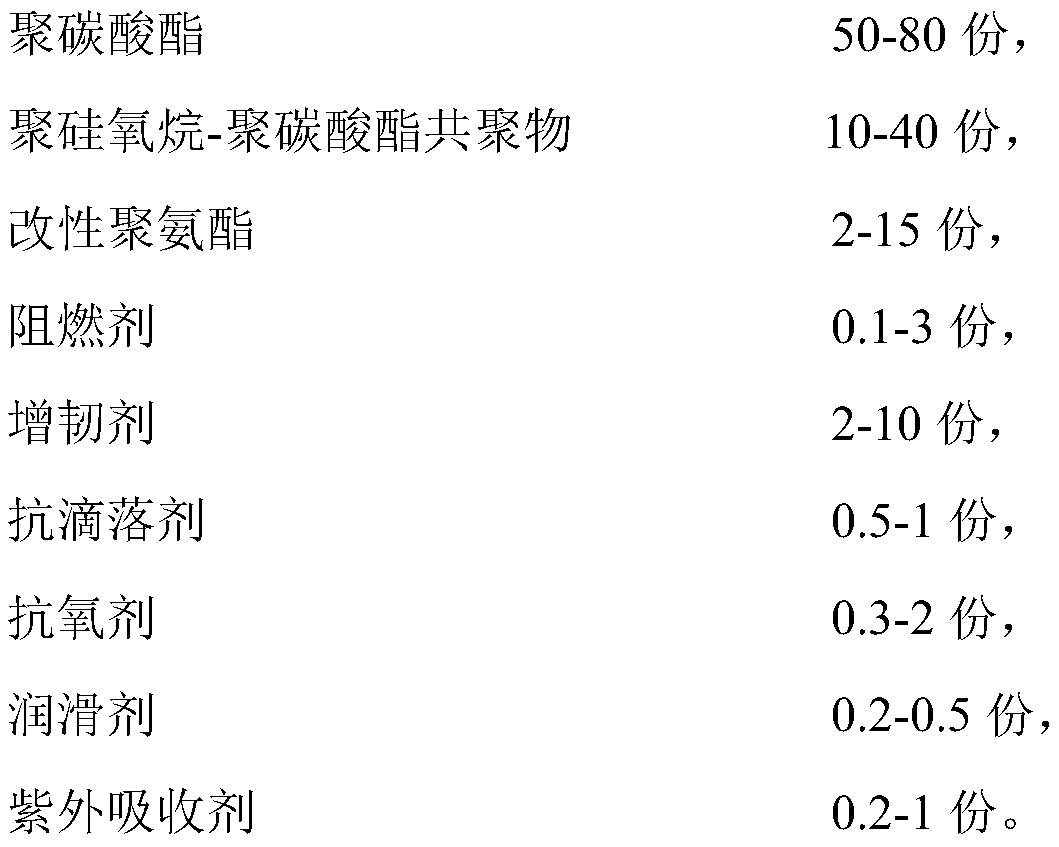

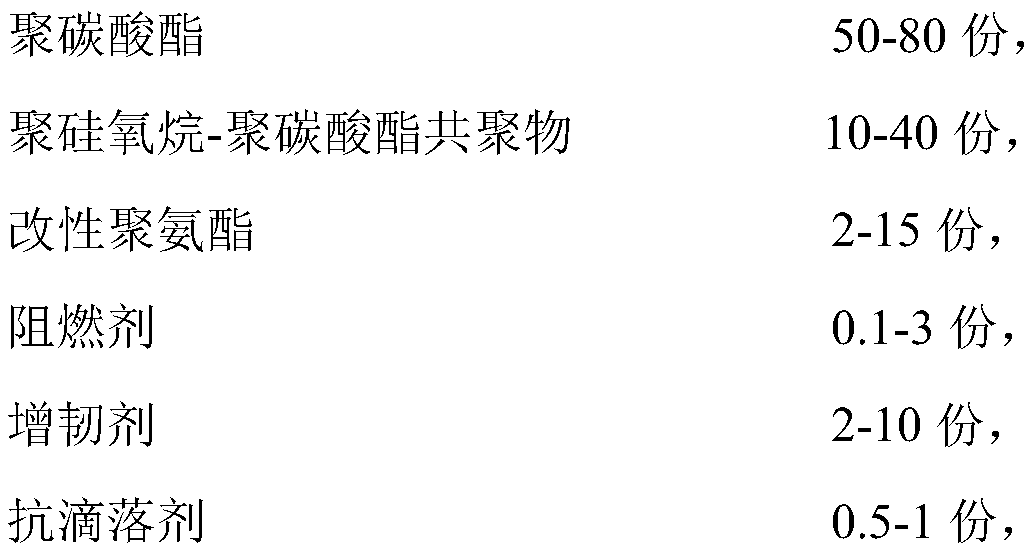

[0038] Weigh each component according to the weight ratio in Table 1;

[0039] Mix the weighed flame retardant, toughening agent and part of polycarbonate in a high-speed mixer, enter from the main feed of the twin-screw extruder, and obtain flame-retardant masterbatch through melt extrusion, cooling, drying and pelletizing. , the weight ratio of flame retardant and polycarbonate in the flame retardant masterbatch is 1:15; the flame retardant masterbatch and other remaining raw material components are mixed in a high-speed mixer, from the main part of the twin-screw extruder Feeding in, through melt extrusion, cooling, drying, and pelletizing to obtain samples. The screw extruder is a co-rotating twin-screw extruder, the length-diameter ratio of the screw is 50, and the screw bar...

Embodiment 2

[0041] This embodiment provides a halogen-free flame retardant polycarbonate alloy resistant to alternating heat and cold and a preparation method thereof.

Embodiment 3

[0043] This embodiment provides a halogen-free flame retardant polycarbonate alloy resistant to alternating heat and cold and a preparation method thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com