A polymer positive temperature coefficient heat-sensitive ceramic material and its preparation method

A positive temperature coefficient, polymer material technology, applied in the field of polymer positive temperature coefficient heat-sensitive ceramic materials and its preparation, can solve the problems of low room temperature resistivity, low room temperature resistivity, room temperature high resistivity, etc., and achieve low room temperature resistance rate, low room temperature resistivity, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

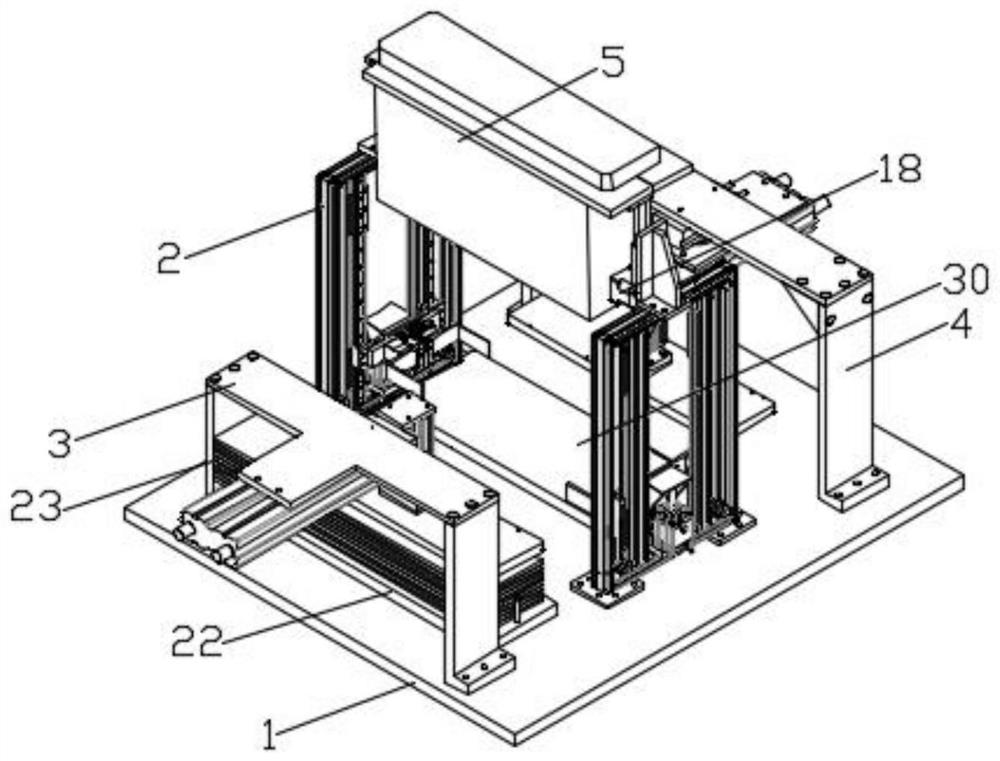

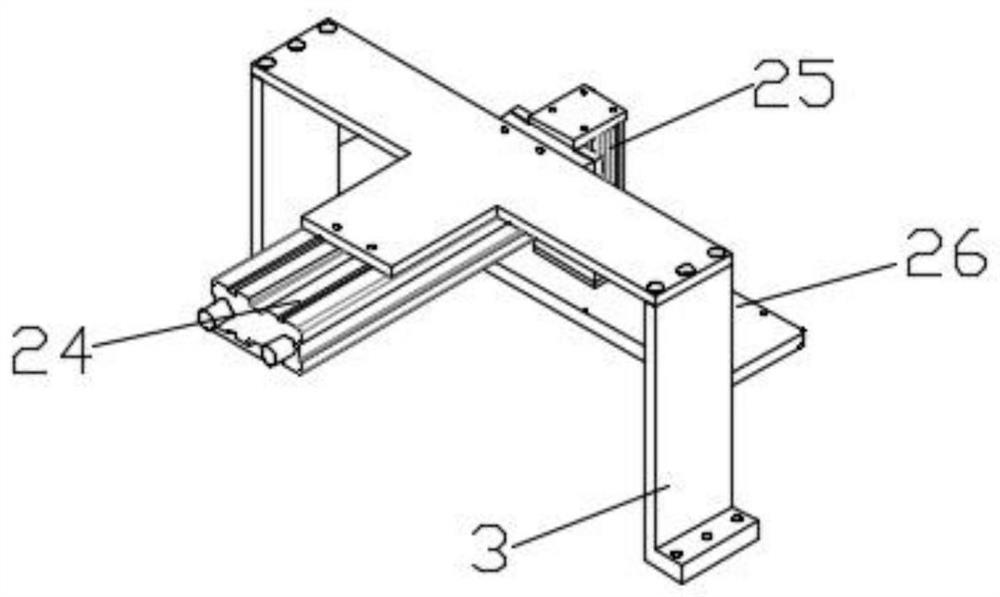

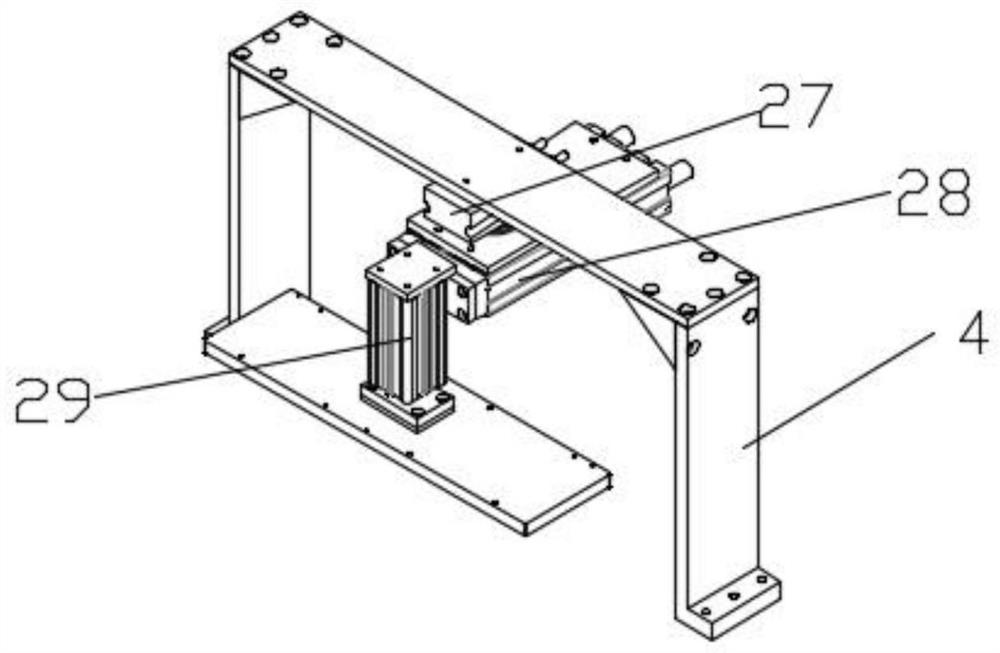

Image

Examples

Embodiment 1

[0033] A polymer positive temperature coefficient heat-sensitive ceramic material is prepared from the following parts by weight of raw materials: 65 parts of BaTiO 3 , 25 parts of PbTiO 3 , 5 parts Cr, 3 parts Ni, 0.5 parts CaCO 3 , 0.4 part SiO 2 , 0.2 part Al 2 O 3 , 0.1 part of Nb 2 O 5 , 0.03 part of MnCO 3 , 20 parts of thermosetting polymer materials;

[0034] Wherein, this polymer positive temperature coefficient thermosensitive ceramic material is prepared through the following steps:

[0035] Step 1: Weigh each raw material according to the above weight portion, and mix the BaTiO 3 , Nb 2 O 5 , PbTiO 3 , Al 2 O 3 , SiO 2 , CaCO 3 , MnCO 3 Mixing to obtain mixture A, wet ball milling, and drying to obtain ball abrasive A;

[0036] Step 2: Mix the ball abrasive A with Cr and Ni, and perform the dual-frequency ultrasonic alternating oscillation treatment for 2 hours to obtain the full batch. Take the polyvinyl alcohol aqueous solution equivalent to 7% o...

Embodiment 2

[0042] A polymer positive temperature coefficient heat-sensitive ceramic material is prepared from the following parts by weight of raw materials: 60 parts of BaTiO 3 , 30 parts of PbTiO 3 , 8 parts Cr, 6 parts Ni, 1 part CaCO 3 , 0.8 parts of SiO 2 , 0.4 part Al 2 O 3 , 0.15 part of Nb 2 O 5 , 0.05 part of MnCO 3 , 30 parts of thermosetting polymer materials;

[0043] Wherein, step 2: mixing the ball abrasive A with Cr and Ni, and performing the dual-frequency ultrasonic alternating oscillation treatment for 3 hours to obtain the full batch, taking the polyvinyl alcohol aqueous solution equivalent to 9% of the mass of the full batch and 1% of glycerol and the full batch, The thermosetting polymer material is mixed evenly, granulated, and passed through a 60-mesh sieve to obtain a granulated material. The granulated material is pressed and formed at 150 MPa to obtain a green body. Sintering and infiltration for 15min to prepare a heat-sensitive ceramic material;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com