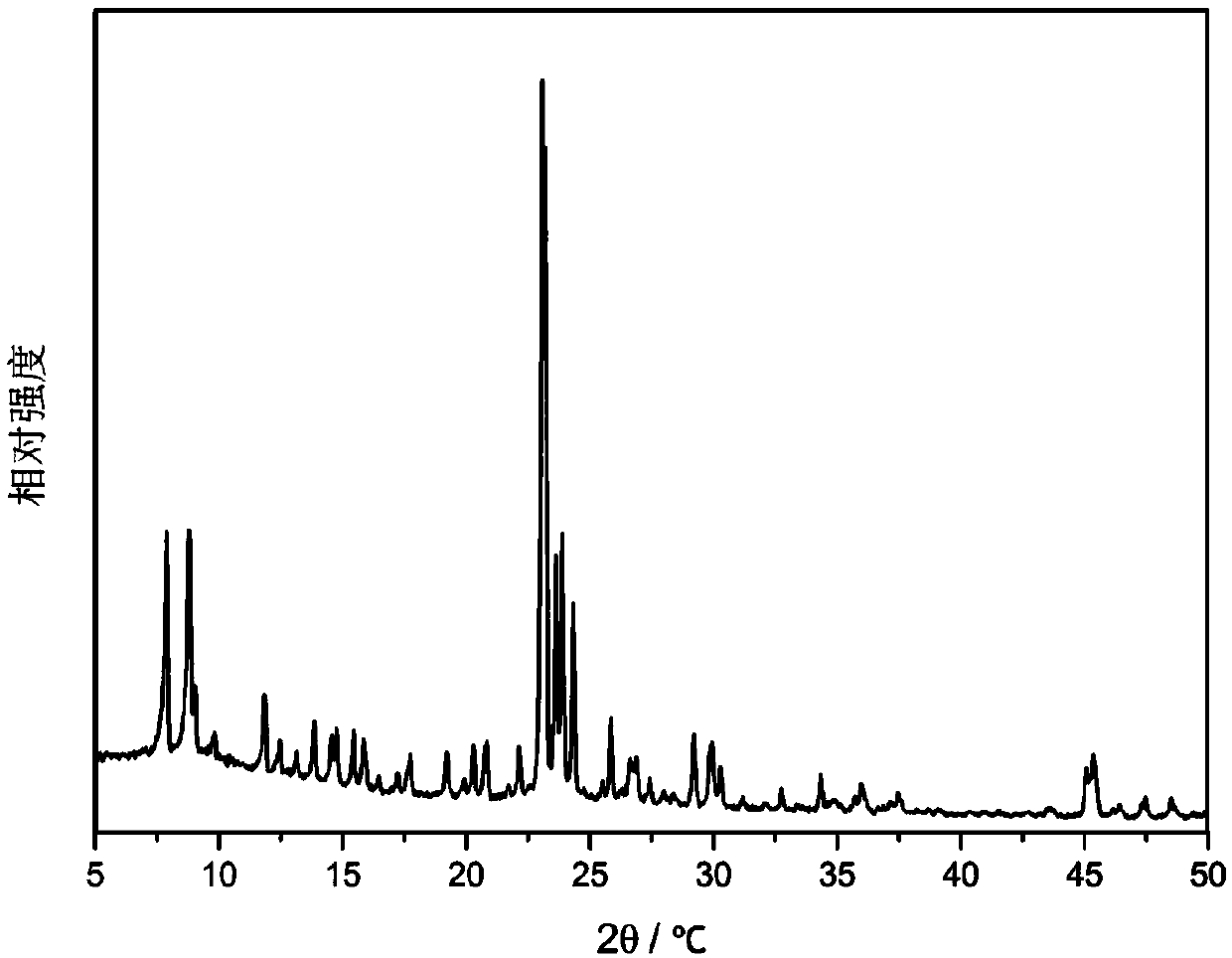

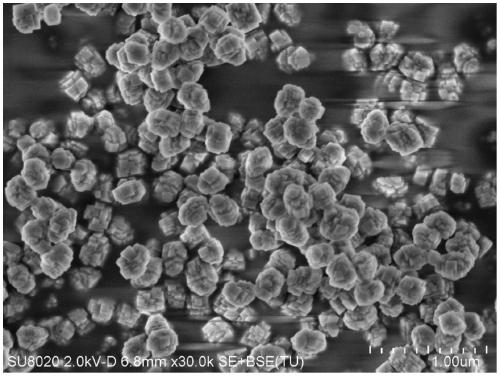

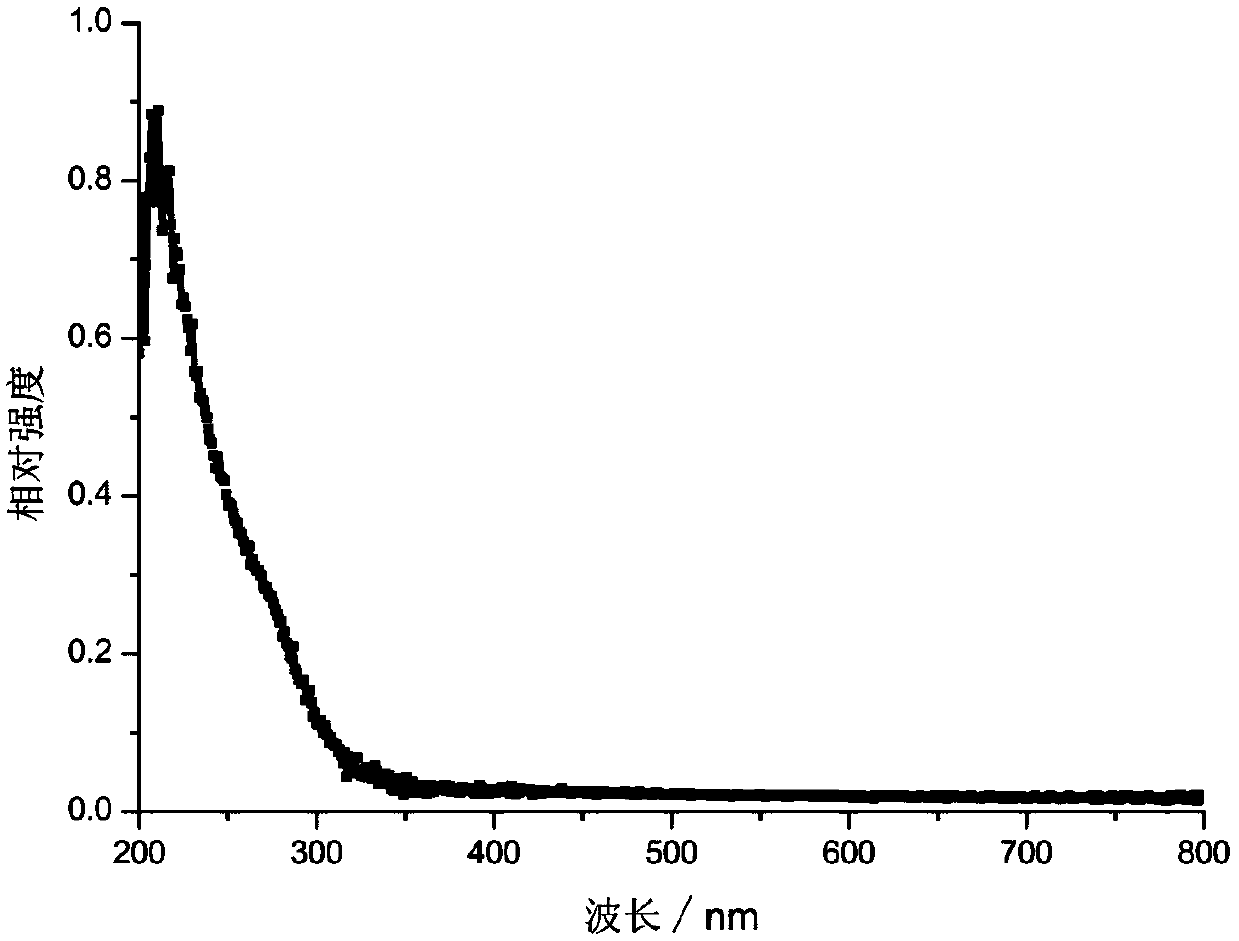

Preparation method of hierarchical pore TS-1 molecular sieve

A TS-1, multi-stage pore technology, applied in molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic metal phosphates, etc., to achieve narrow pore size distribution and prevent precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0134] According to one embodiment of the present application, the method for preparing the hierarchically porous TS-1 molecular sieve is as follows:

[0135] a) Add silicate, titanate and polyols into a three-necked flask and mix evenly, carry out transesterification reaction under stirring, connect to a distillation device, protect with nitrogen, the reaction temperature is between 80-180°C, and the reaction time is between After 2 to 10 hours, the conversion rate of the transesterification reaction is between 60% and 80%.

[0136] b) Connect the device after the reaction in step a) to a water pump or an oil pump for vacuum distillation to make the transesterification reaction more complete. The vacuum degree of the control system is 0.01-5KPa, the reaction temperature is between 170-230°C, and the reaction time is between After 0.5-5 hours, the conversion rate of the transesterification reaction is greater than 90%, and the silicon-titanium ester polymer is obtained.

[01...

Embodiment 1

[0162] The specific batching process is as follows: add 5g tetraethyl titanate, 0.29g tetraethyl titanate and 10g polyethylene glycol 200 into the three-necked flask and mix evenly, carry out the transesterification reaction under stirring, connect the distillation device, and pass nitrogen gas Protection, heating up to 175°C, reaction time 5 hours, the conversion rate of the transesterification reaction is 75%, connected to a water pump for vacuum distillation to make the transesterification reaction more complete, control the vacuum degree of the system at 3KPa, the reaction temperature is 200°C, the reaction After 1 hour, the conversion rate of the transesterification reaction was 92%, and the silicon-titanium polyethylene glycol ester polymer was obtained. The obtained silicon-titanium polyethylene glycol ester polymer was mixed with 8g tetrapropylammonium hydroxide (25wt.% aqueous solution) and 12g water, stirred and aged at room temperature for 2 hours, and then transferr...

Embodiment 2

[0164] The specific batching process is as follows: add 5g tetraethyl titanate, 0.05g tetraethyl titanate and 3.13g ethylene glycol into the three-necked flask and mix evenly, carry out transesterification reaction under stirring, connect the distillation device, and pass nitrogen protection , the temperature was raised to 100°C, the reaction time was 5 hours, and the conversion rate of the transesterification reaction was 70%. Connected to a water pump for vacuum distillation to make the transesterification reaction more complete, the vacuum degree of the control system was at 3KPa, the reaction temperature was 170°C, and the reaction time was After 1 hour, the conversion rate of the transesterification reaction was 90%, and the silicon-titanium glycol ester polymer was obtained. The obtained silicon-titanium glycol ester polymer was mixed with 2g tetrapropylammonium hydroxide (25%wt. aqueous solution) and 3g water, stirred and aged at room temperature for 2 hours, and then tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com