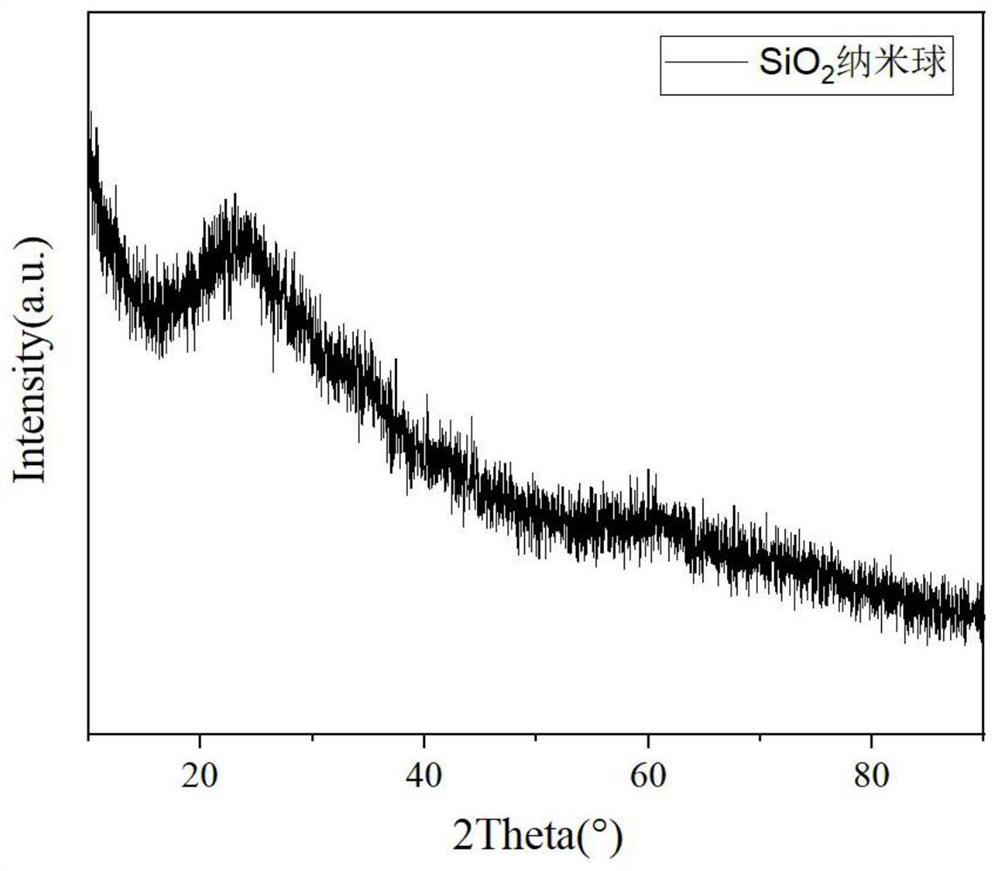

Mesoporous silica nanosphere with ultrahigh specific surface area and preparation method thereof

A mesoporous silica, ultra-high specific surface area technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of large particle diameter, difficult pore size and shape, particle agglomeration, etc., to achieve particle size Easy to control, short preparation time, good spherical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing mesoporous silica nanospheres with an ultrahigh specific surface area, comprising the following steps:

[0051] (1) Preparation of precursor solution:

[0052] Dissolve ethyl orthosilicate in ethanol solution, and mix evenly with magnetic stirring to obtain precursor solution A;

[0053] Mix ammonia water, water and pore-forming agent uniformly to obtain precursor solution B;

[0054] (2) Equally draw the precursor solutions A and B, place them on a micro-injection pump, and mix them quickly through a microchannel reactor at the same injection speed to obtain a microemulsion;

[0055] (3) After the microemulsion is left to stand, it is subjected to demulsification, suction filtration, washing, drying, and high-temperature calcination to obtain the mesoporous silica nanospheres with ultra-high specific surface area.

[0056] Preferably, in the precursor solution A, the volume ratio of ethyl tetrasilicate to ethanol solution is 1-10:450;

[0057]...

Embodiment 1

[0067] The specific operation steps are as follows:

[0068] (1) Dissolve 5ml of ethyl orthosilicate in 450ml of ethanol solution (the volume ratio of ethanol to water in the ethanol solution is 1:1), stir and mix evenly to obtain the precursor A;

[0069] (2) After dissolving 4.10g of cetyltrimethylammonium bromide (CTAB) in 450ml of deionized water, quickly drop 15ml of ammonia water to obtain the precursor solution B;

[0070] (3) Take equal amounts of precursor solutions A and B, place them on a micro-injection pump, set the injection speed to 60ml / min, and mix quickly through a microchannel reactor to prepare a transparent microemulsion by mixing precursor solution A and precursor solution B system;

[0071] (4) After the microemulsion was allowed to stand for 20 minutes, add 100 ml of acetone, heat and reflux at 60° C. for 20 minutes to make the colloid coagulate and achieve the effect of breaking the emulsion, and then suction filter at room temperature;

[0072] Afte...

Embodiment 2

[0078] The operating steps of Example 2 are the same as those of Example 1, except that the amount of cetyltrimethylammonium bromide (CTAB) is 1.00 g.

[0079] The silicon dioxide nanosphere prepared in this embodiment is measured, and the specific surface area is 1322m 2 / g, the pore volume is 0.99cm 3 / g and an average pore diameter of 3nm ultra-high specific surface area mesoporous silica nanospheres.

[0080] Compared with Example 1, it can be seen that the amount of pore forming agent will affect the specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com