Preparation of molybdenum carbide supported nickel-based catalyst, and application of molybdenum carbide supported nickel-based catalyst in ethanol preparation through carbon dioxide hydrogenation

A technology for supporting catalyst and carbon dioxide, which is applied to nickel-based catalyst and its preparation and application in carbon dioxide hydrogenation to prepare ethanol, can solve the problems of low product ethanol selectivity, low catalyst conversion rate, and high reaction energy consumption, and achieves preparation Simple method, large market application value, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

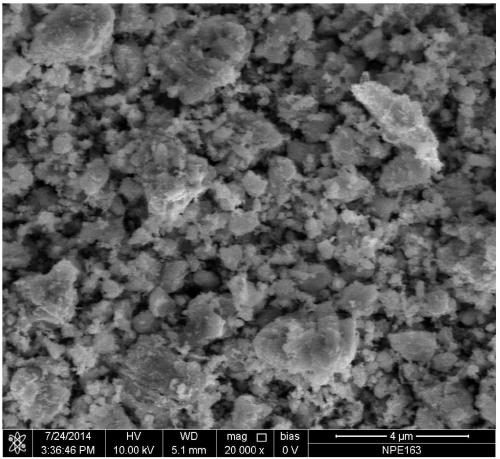

[0031] Preparation of 5% Ni / Mo 2 Sample of C: Weigh Ni(NO 3 ) 2 ·nH 2 O 0.0662g, 1.039g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in deionized water to form a solution. Stir at room temperature for 2 to 3 hours, let stand for 2 hours, then dry at 110°C, and then bake at 550°C for 4 hours in an air atmosphere to obtain NiMoO x composite oxides.

[0032] Shape the composite oxide prepared above (20-40 meshes), weigh the amount of catalyst required for the reaction and place it in a quartz reactor, 4 -H2 (CH 4 / H 2 =1:4) in a mixed atmosphere of temperature-programmed carbonization, when the temperature rises from room temperature to 300°C, the heating rate is 5°C / min, and from 300°C to the final carbonization temperature (700°C), the heating rate is 1°C / min, At the final carbonization temperature, keep the temperature constant for 120 minutes, drop to room temperature in an argon atmosphere, and use 1% O 2 / Ar passivation for 12h, finally get NiMo 2 C catalyst (labe...

Embodiment 2

[0034] Preparation of 5% Ni / Mo 2 The sample of C: experiment with the method similar to embodiment 1, the content of preparation nickel becomes 1%, Ni(NO 3 ) 2 ·6H 2 The quality of O was changed to 0.01324g, and other specific steps were referred to Example 1 to obtain product A2.

Embodiment 3

[0036] Carry out experiment with the method similar to embodiment 1, ammonium molybdate is changed into molybdenum oxide, other specific steps refer to embodiment 1, can obtain product B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com