Preparation method of composite fiber film

A composite fiber membrane and composite fiber technology, which is applied in fiber processing, textile and papermaking, non-woven fabrics, etc., to achieve wide application prospects, simple and flexible processes, and fewer types of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

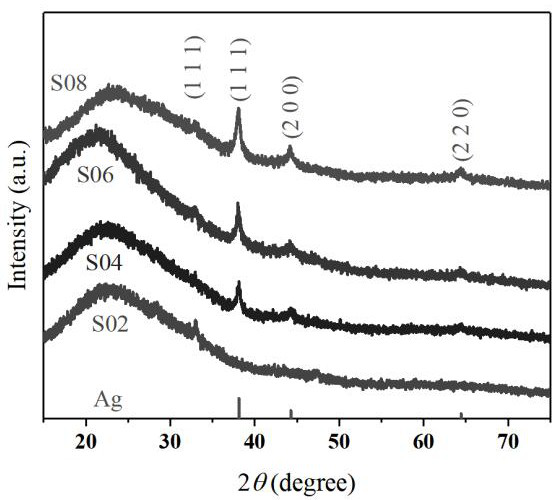

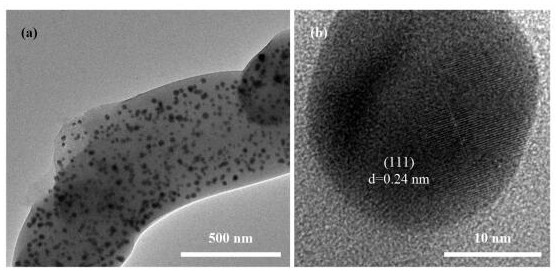

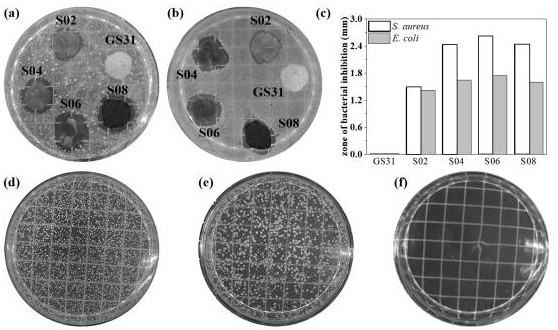

[0044]Weigh 2.000 g of gelatin, 0.17 g of silver nitrate (or 0.41 g of chloroauric acid) and 0.666 g of silk fibroin in a beaker, slowly add 5 mL of formic acid dropwise, and stir in a constant temperature water bath at 35°C until transparent and uniform And the solution has a certain viscosity, the positive and negative voltages are -7 kV and +15 kV respectively, and the injection speed is 0.2 mm min -1 , the spinning distance between the needle and the receiving plate is 15 cm, the left and right translation distance of the needle is 10 mm, and the translation speed is 200 mm s -1 Fibrous membranes were obtained under the spinning conditions. The film was placed in a vacuum oven at 60 °C overnight to remove excess water and residual solvent, and then placed under ultraviolet light for 2 h to completely reduce the precious metals on the fiber film. And through water vapor transmission test and antibacterial performance test to characterize its related properties.

[0045] ...

Embodiment 2

[0049] Weigh 3.000 g of gelatin, 0.41 g of chloroauric acid and 1.000 g of silk fibroin into a beaker, slowly add 7.5 mL of formic acid dropwise, and stir in a constant temperature water bath at 35 °C until a transparent and uniform solution with a certain viscosity is obtained. The positive and negative voltages were -10 kV and +12.5 kV respectively, the injection speed was 0.15 mm min-1, the spinning distance between the needle and the receiving plate was 20 cm, the left and right translation distance of the needle was 15 mm, and the translation speed was 200 mm s Fibrous membranes were obtained under the spinning conditions of -1. The film was kept in a vacuum oven at 60°C overnight to remove excess water and residual solvent, and then transferred to a vacuum oven at 160°C for 2 h to heat-treat the fiber membrane. And through water vapor transmission test and antibacterial performance test to characterize its related properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com