Sealing method of acrylic glass micro-fluidic chip

A microfluidic chip and acrylic technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem that is not suitable for complex structures and complex sealing of multi-layer chips, and is not suitable for large areas And multi-layer chip sealing, reducing solvent solubility and other issues, to avoid corrosive damage and blockage channels, improve operability and applicability, and avoid obvious changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 double-layer PMMA microfluidic chip sealing

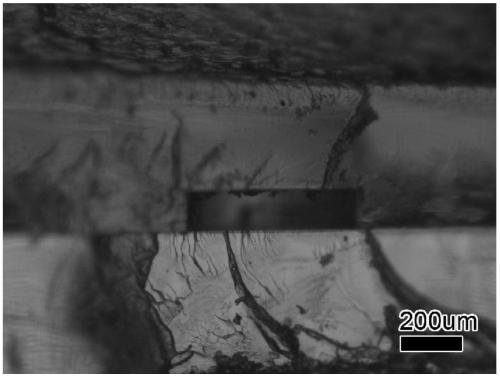

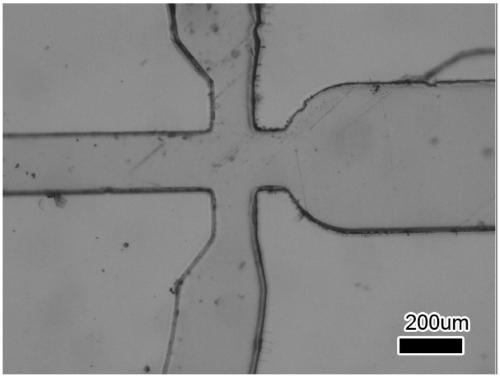

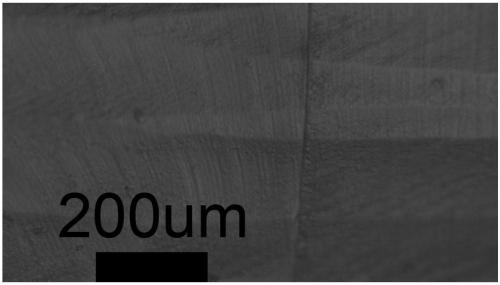

[0088] The PMMA material chip with a complex microchannel structure is self-made, (patent application number 201611114889.1, Example 3) and the other is a PMMA cover sheet, both of which have a thickness of 1mm and a size of 8cm x 8cm. Dilute 0.5ml of PMMA glue chloroform into 2ml of hexane to form an adhesion promoter. Put the PMMA chip with complex microchannel structure and the PMMA cover sheet together, take 0.2ml of adhesion promoter and add it to the two PMMA sheets, put it into the tablet machine, the temperature of the pressure plate on the tablet machine is 50 degrees, and apply 0.5Mpa And keep it for 2 minutes, vacuum to remove excess liquid, and complete the sealing after 10 minutes. The micrographs of microchannel section, front surface and sealing surface after sealing are as follows: figure 1 , figure 2 and image 3 shown. The channel size measurement results show that the original height of ...

Embodiment 2

[0089] Embodiment 2 Double-layer PMMA microfluidic chip sealing

[0090] The PMMA material chip with a complex microchannel structure is self-made, and the other is a PMMA cover sheet. The thickness of both is 1mm, and the size is 8cm x 8cm. Dilute 0.9ml of PMMA glue chloroform into 2ml of hexane to form an adhesion promoter. Combine the PMMA chip with a complex microchannel structure and the PMMA cover sheet, add 0.2ml of adhesion promoter into the two PMMA sheets, put it into a tablet press, apply a pressure of 0.4Mpa at room temperature, and keep it for 10 minutes to complete the sealing. catch. The microchannel cross section after sealing, the front surface, the photomicrograph of the sealing surface, the channel size measurement results, the roughness test of the original PMMA microchannel and the microchannel after sealing are similar to those in Example 1. The depth of the cover slip embedded in the channel was less than 2 μm, which was less than 2% of the original ch...

Embodiment 3

[0091] Embodiment 3 double-layer PMMA microfluidic chip sealing

[0092] The PMMA material chip with a complex microchannel structure is self-made, and the other is a PMMA cover sheet. The thickness of both is 1mm, and the size is 8cm x 8cm. Dilute 0.9ml of PMMA glue chloroform into 2ml of cyclohexane to form an adhesion promoter. Combine the PMMA chip with complex microchannel structure and the PMMA cover sheet, take 0.2ml of adhesion promoter and add it to the two PMMA sheets, then put it into the tablet machine, apply 0.6Mpa pressure at room temperature, and keep it for 5 minutes Complete the seal. The microchannel cross section after sealing, the front surface, the photomicrograph of the sealing surface, the channel size measurement results, the roughness test of the original PMMA microchannel and the microchannel after sealing are similar to those in Example 1. The depth of the cover slip embedded in the channel was less than 2 μm, which was less than 2% of the original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com