Preparation method of low-temperature lithium ion battery

A lithium-ion battery, low-temperature technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as limited degree, achieve high energy density, improve low-temperature electrochemical performance, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

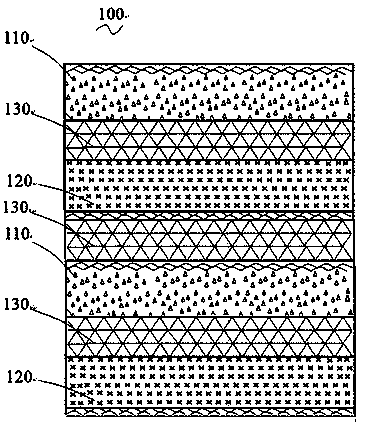

[0033] Such as figure 1 , 2 As shown, a method for preparing a low-temperature lithium-ion battery 100 includes the following steps,

[0034] Step 1: Add 7 grams of polyvinylidene fluoride copolymer (PVDF-HFP) into 180 grams of acetone to make it fully stirred and dissolved to form a viscous liquid.

[0035] Step 2: The production procedure of the positive electrode sheet 110 is as follows: 60 grams of plasticizer DBP and 140 grams of lithium iron phosphate positive electrode material (lithium iron phosphate material with secondary micron particles composed of primary nanoparticles) and 2.5% carbon The nanotube conductive agent and 1.5% SP conductive agent are fully mixed and added to the above viscous liquid, and stirred evenly with a mixer to form a viscous positive electrode slurry. The obtained positive electrode slurry was evenly coated on both sides of the carbon-coated aluminum foil, and kept in a vacuum oven at 80° C. for 4 hours to remove the solvent acetone. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com